cone to the bottom of the PVC, allowing the slight overlap to

cover the seam. In reviewing the prototype construction, this is

also more accurate.

Once the silos were completed, I used two-pipe brass railings

from Mike Rose Hobbies

for the walkway around

the top. These railings were the perfect solution, since the

brass easily forms to the radius of the silos. The trick to instal-

lation is laying the railings flat on a piece of masking tape and

pre-marking the holes with the correct spacing to accept the

pins of the railings. Then apply the masking tape around the

silos, and drill the holes. Once all the holes are drilled, remove

the masking tape and gently bend the railings around the silo

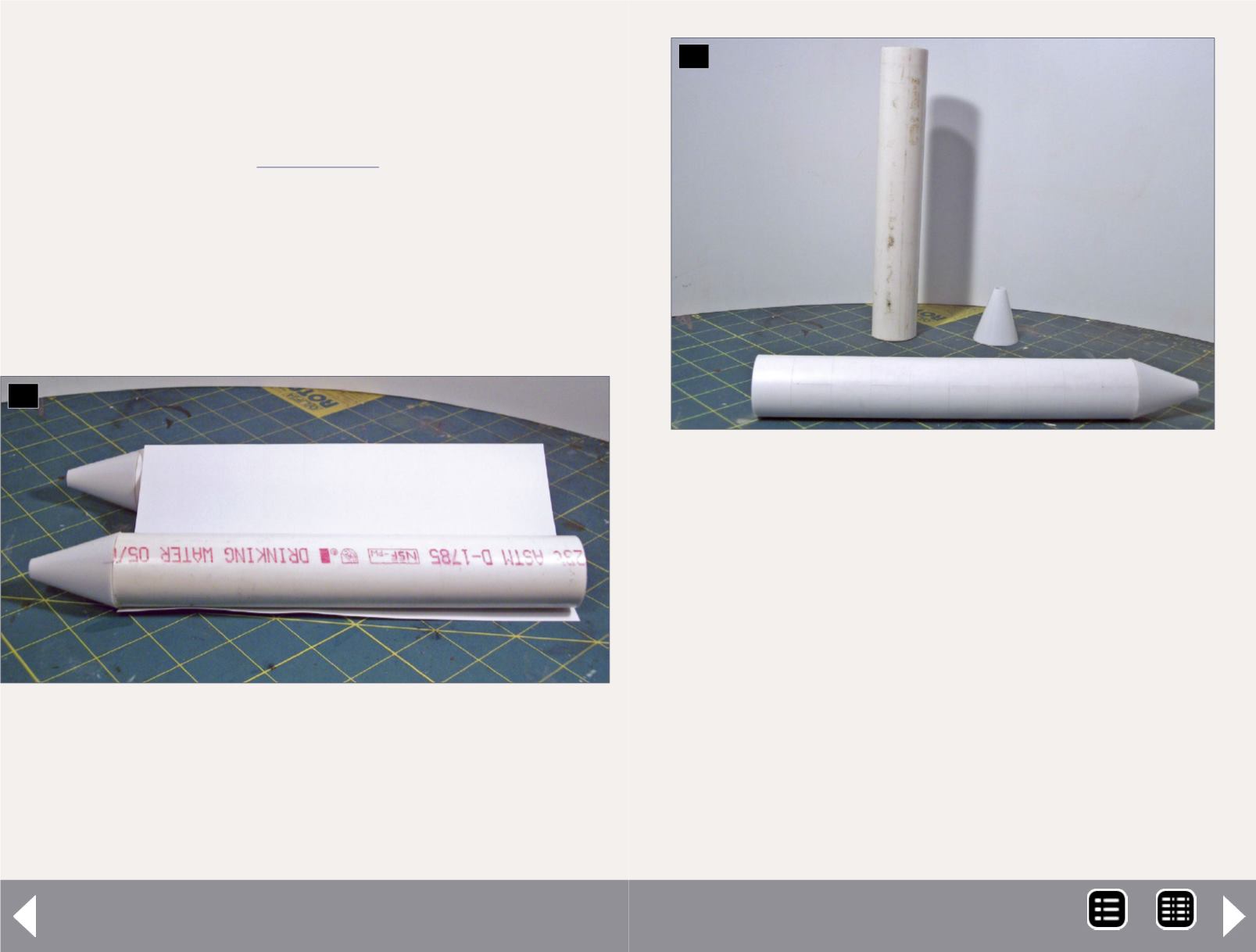

22. This photos shows the styrene temporarily tacked

with CA cement to the PVC silo. The next step is slowly

wrap the styrene around the PVC spreading CA cement

every half inch and firmly pressing the styrene against

the PVC to prevent bubbles from getting between the

PVC and styrene.

22

Agway Feed Mill - 12

and install the pins into the holes. If you are careful, the tape

can be reused on several silos.

The last silo to be constructed at the end was done using 2” PVC

laminated with .010” styrene [24-25]. To replicate the proto-

type, I cut the styrene into panels seven scale feet in height and

used the same pounce wheel to create vertical rivet lines every

5’ on the panels. A .030” by .030” strip of styrene was wrapped

around the silo between each panel to represent the segmented

construction of the prototype. After the panels were completed,

I added a .040” roof and more of the brass two-pipe railings in

the same manner as the other 10 silos. [24 and 25].

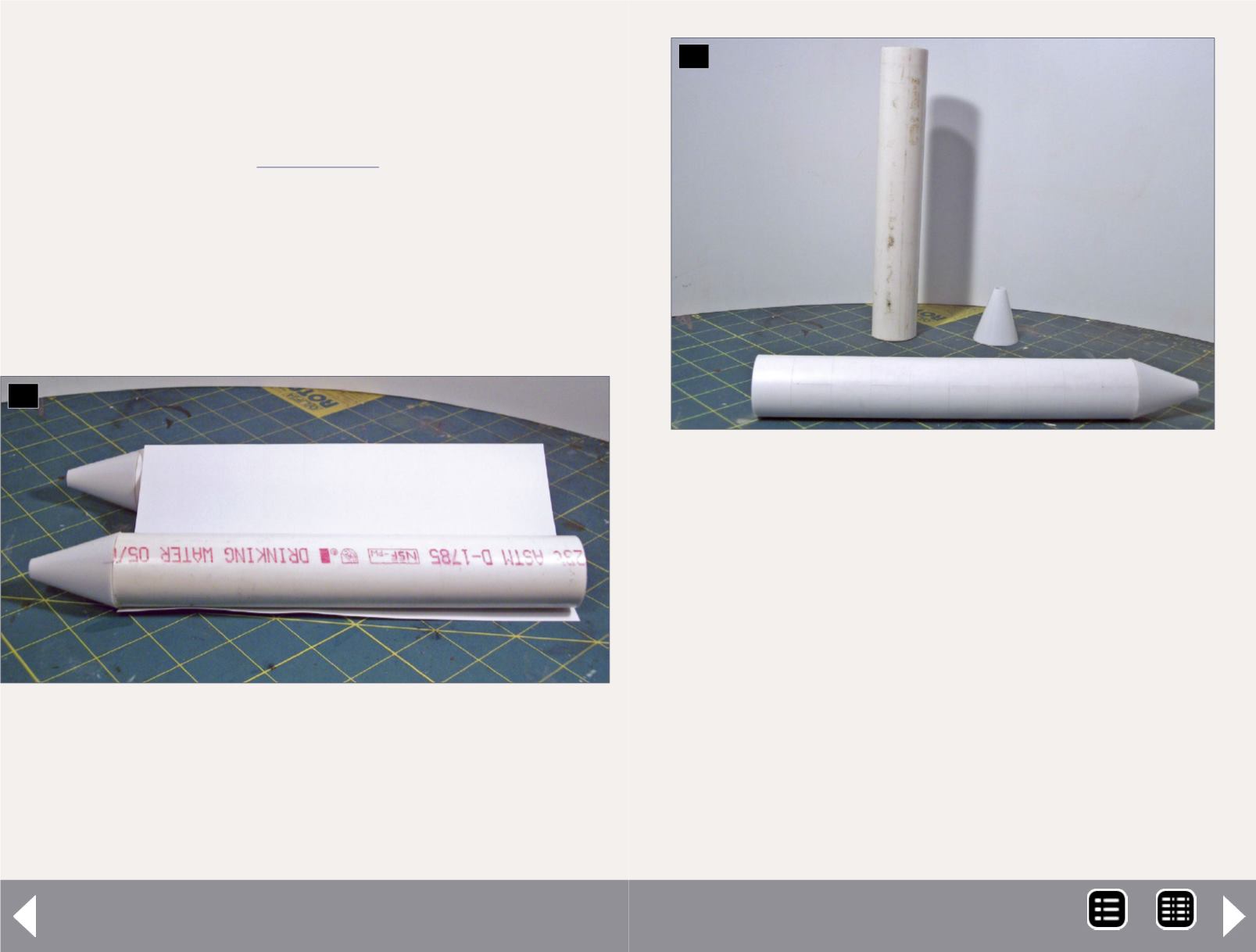

23. This photo shows the completed details of the silos

and base.

23

MRH-Sep 2014