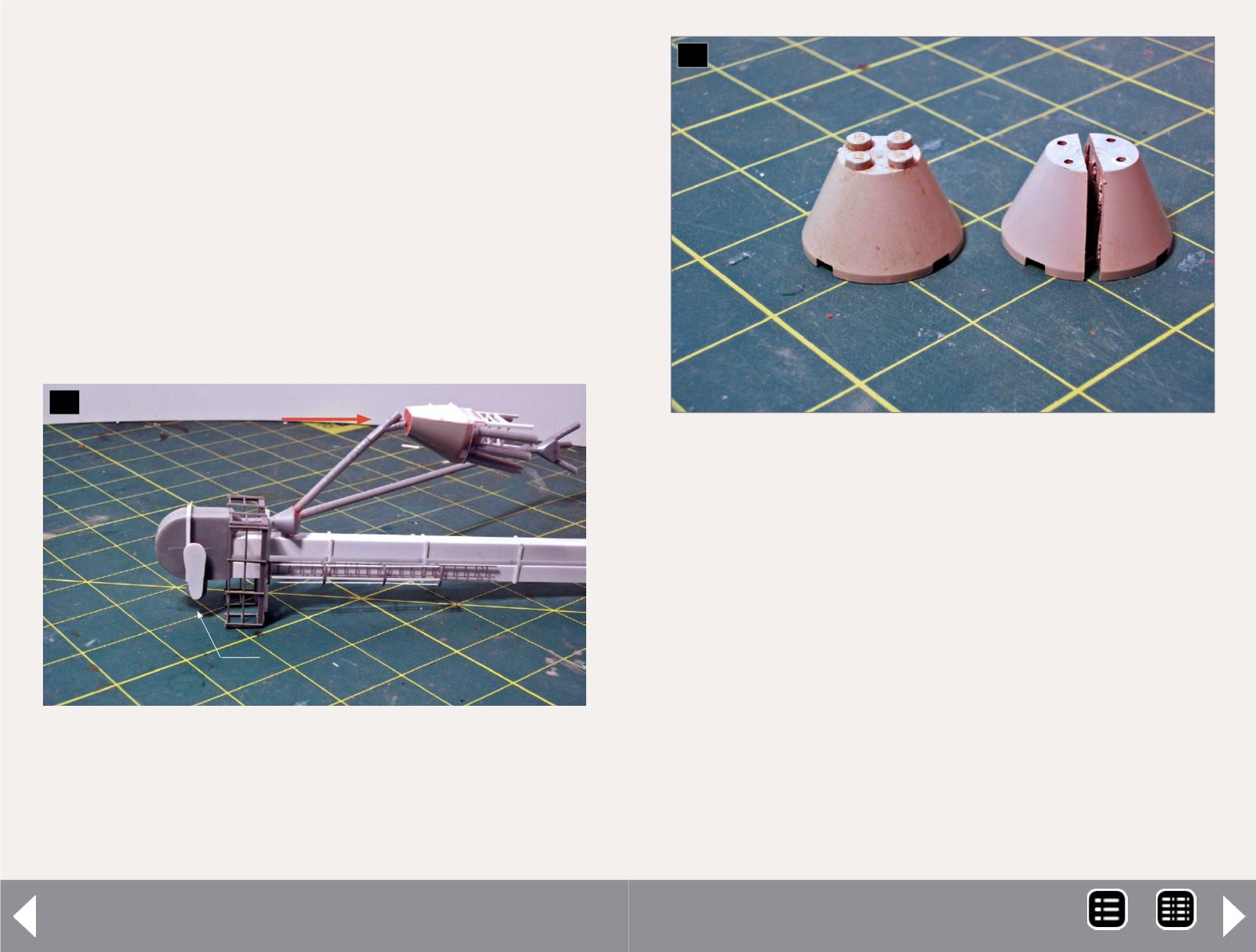

assembled separately by cutting the Tichy railings to the appro-

priate length and then cutting the walkways to match. The

walkway assembly was then braced with .020” x .080” styrene

on the underside. The walkways were attached to the elevator

using Evergreen .060” styrene angle. Once the walkways were

assembled, I assembled the Tichy ladder and cage assembly

based on the dimensions from the bottom of the walkway to

the base of the elevator.

The silo distribution piping was constructed with the piping

supplied with the Rix Products Grain Elevator silo piping cut to

length. The distributor heads themselves were made from Lego

parts and the general construction is shown in [30 through

29. Partially completed feed bin elevator and

distribution head. The unpainted photo illustrates the

general construction of the elevator, head assembly and

pulley guard along with handrails, distributor, and Rix

Products piping.

29

Silo distribution head

Elevator pulley (0.040” styrene)

Agway Feed Mill - 15

33]. Luckily, the parts were scavenged from a very large box of

Lego parts I had when I was a kid ,and none of my children’s

assembled Lego models were harmed. Otherwise I would have

certainly heard from the complaint department about Dad

stealing Legos.

Car unloading shed

The simplest part of the project is the car-unloading shed. This

is as straightforward as assembling a Pikestuff Modern Small

Engine House kit per the instructions to match the general con-

struction of the prototype shown in [2]. The only detail I added

was the overhead door assembly using styrene shapes [34].

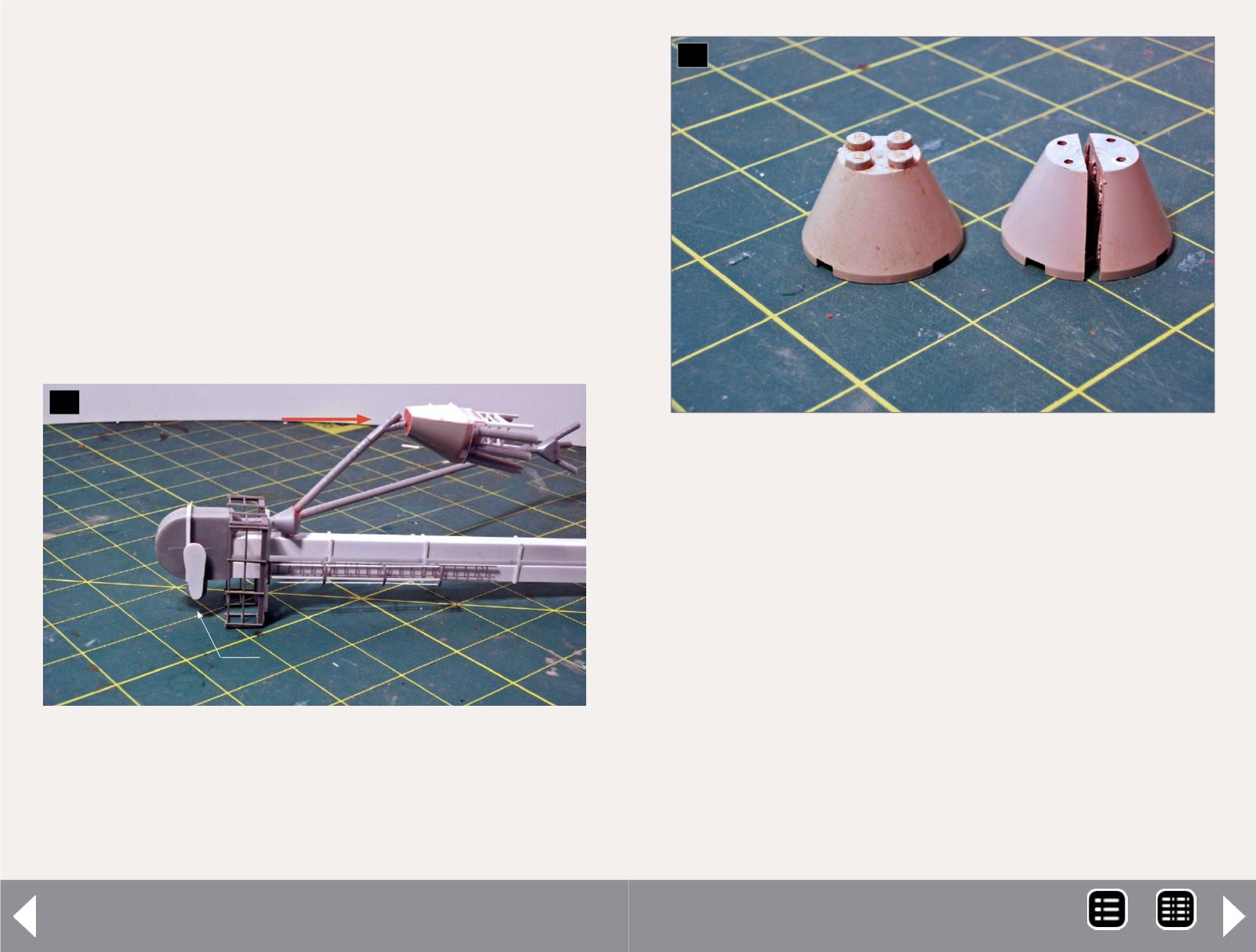

30. The next several photos illustrate how the elevator

distributor head was constructed using a Lego part cut

in half.

30

MRH-Sep 2014