Agway Feed Mill - 6

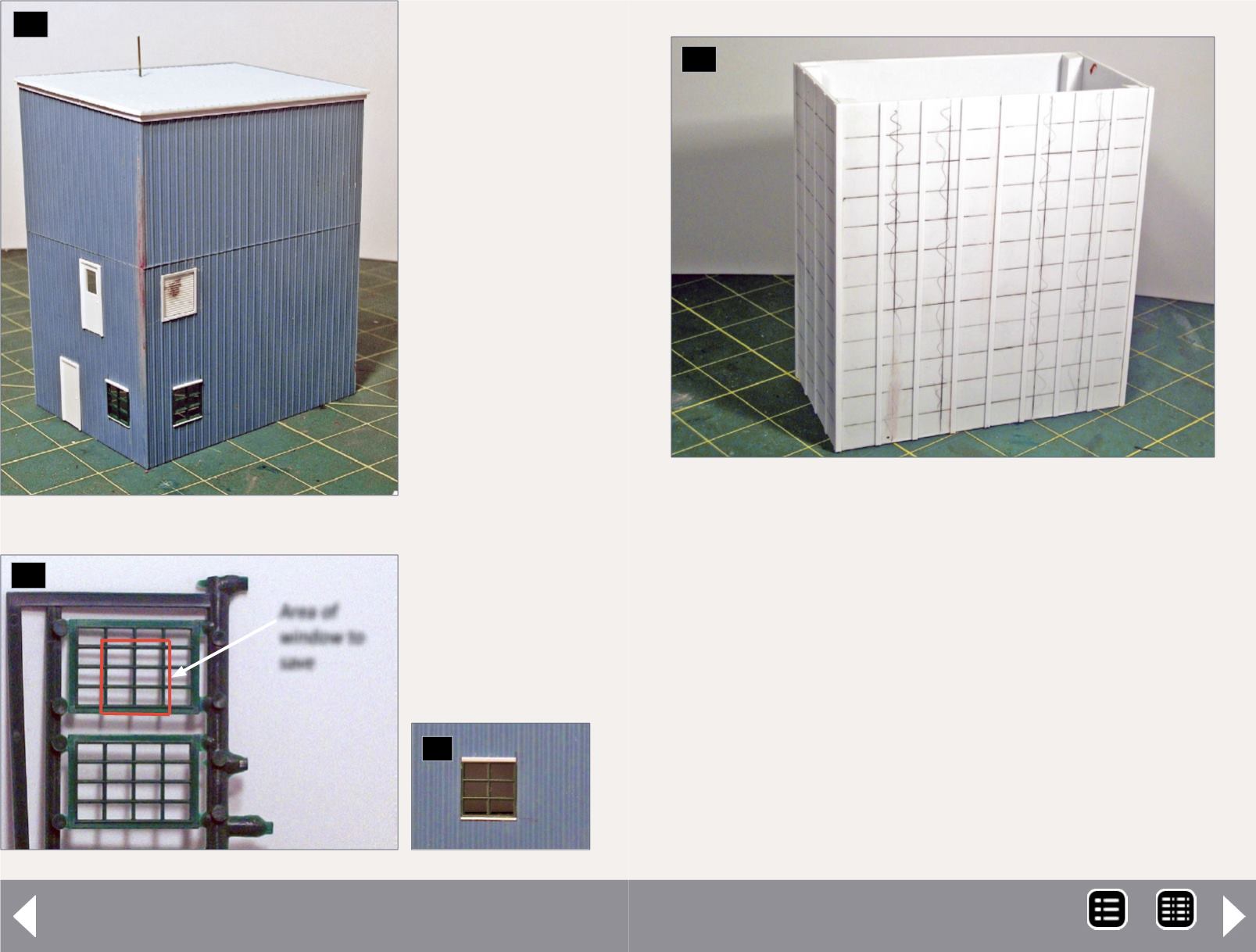

10. Assembled

rear portion of

main structure.

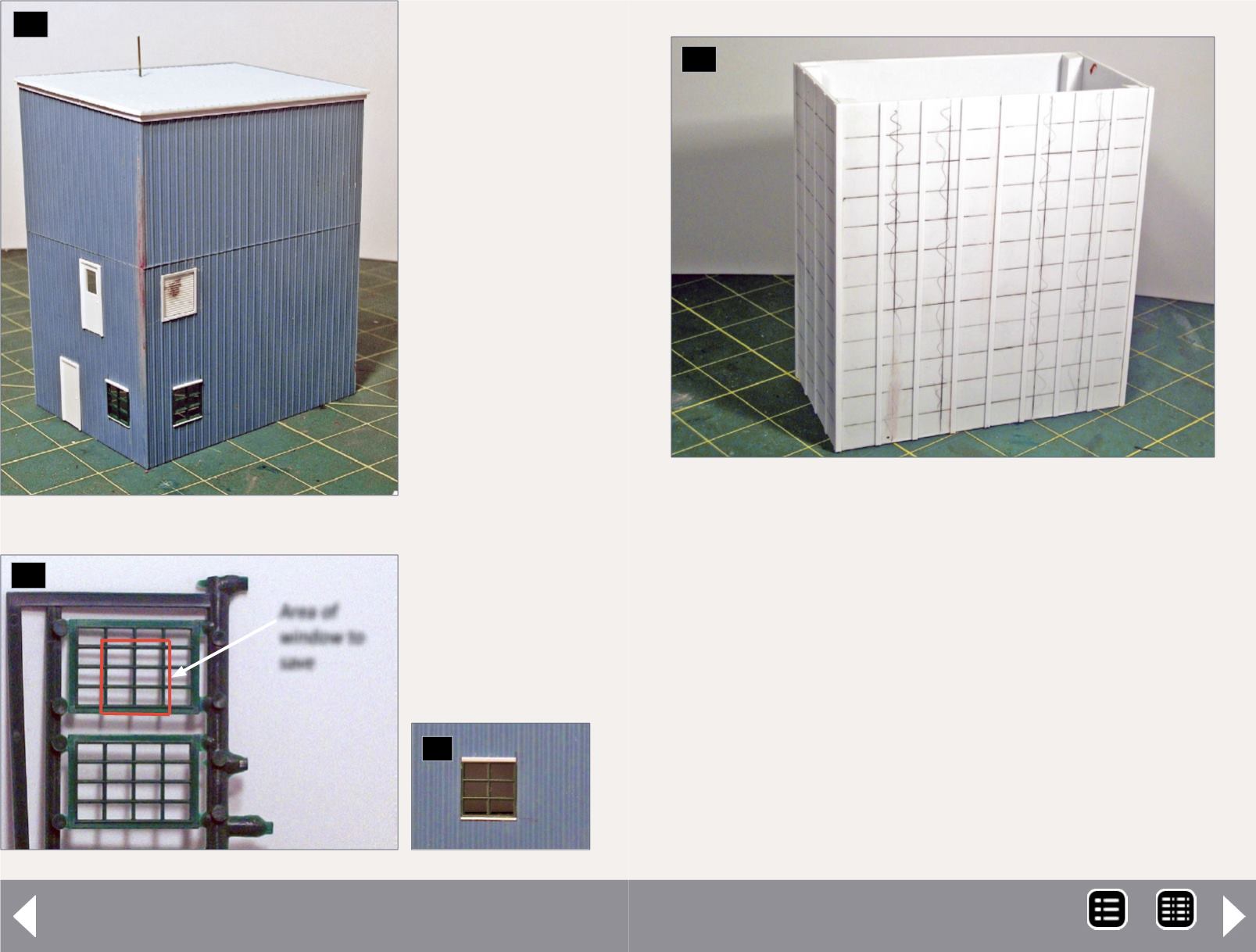

11. This photo

shows the stock

Pikestuff window

included with the

Machine Shop/

Garage and

where to modify

the window.

12. This

photo shows

the modified

Pikestuff window

created by

cutting out the

outside mullions

to match those of

the prototype.

12

10

11

Area of

window to

save

steel siding with cross bracing between each vertical brace. To

complicate things further, the vertical braces were riveted, and

the top portion of each cross brace was sloped, presumably to

prevent rain from accumulating on the outside framing of the

structure.

While this may have made sense on the prototype, modeling

the slope of each cross brace was a bit overwhelming at first,

since the idea of cutting and filing each piece seemed more

effort than it was worth. Ultimately, a relatively simple solution

presented itself. First, the vertical bracing (.060” x .020” strip)

was measured so that each vertical piece was uniformly spaced

as in Illustrations 2-4. Next, using .020” thick sheets with .060”

V-Groove siding cut to the correct width, I cut cross bracing

13. Partially assembled feed bin with vertical bracing.

13

MRH-Sep 2014