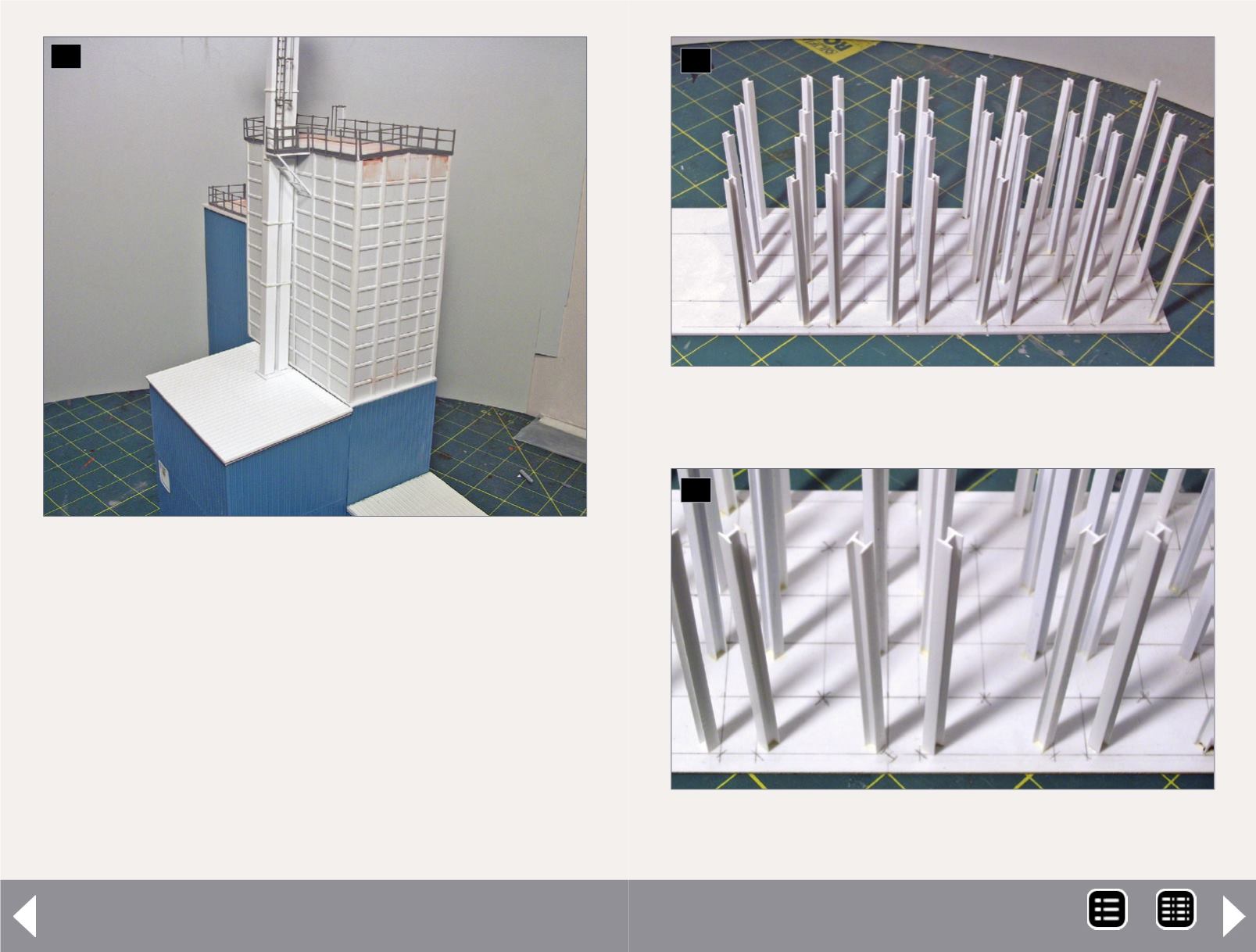

.060” styrene and measured the corners of each silo base for

the column supports [18, 19, and 20].

Silos

Each of the ten silos was constructed of one-inch PVC pipe

wrapped with .010” scribed styrene. PVC pipe was chosen

since it’s relatively inexpensive, and styrene wrapping makes

weld seams easy to replicate [21, 22, and 23]. I started by

gently scribing a .010” styrene sheet with the horizontal weld

17

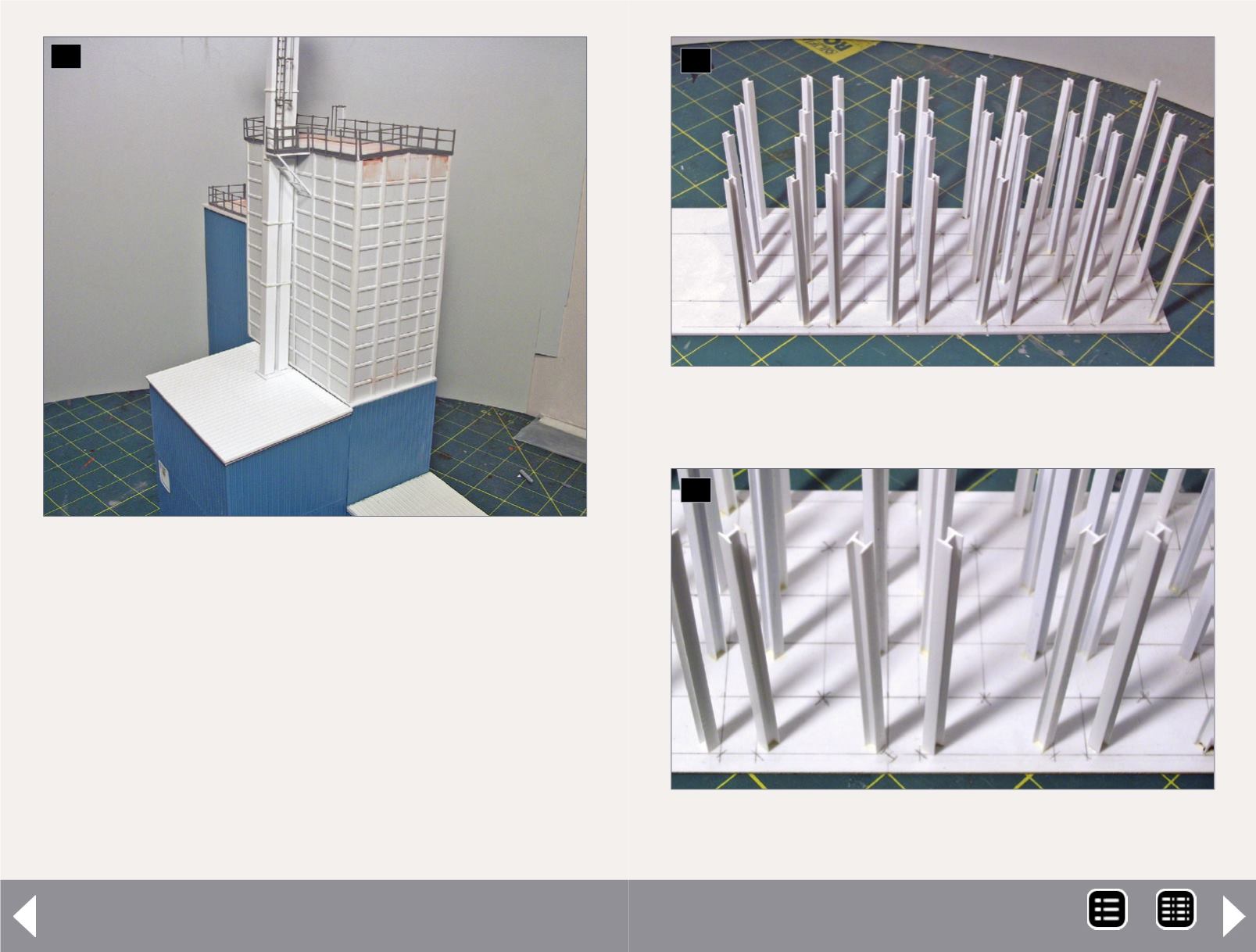

17. View of the completed main structure with feed bin

attached and elevator installed.

Agway Feed Mill - 10

18. Silo base showing the silo supports glued to the

base.

18

19. Close-up of the silo base showing grid markings for

silo centers. The silos are space 1.5” on-center.

19

MRH-Sep 2014