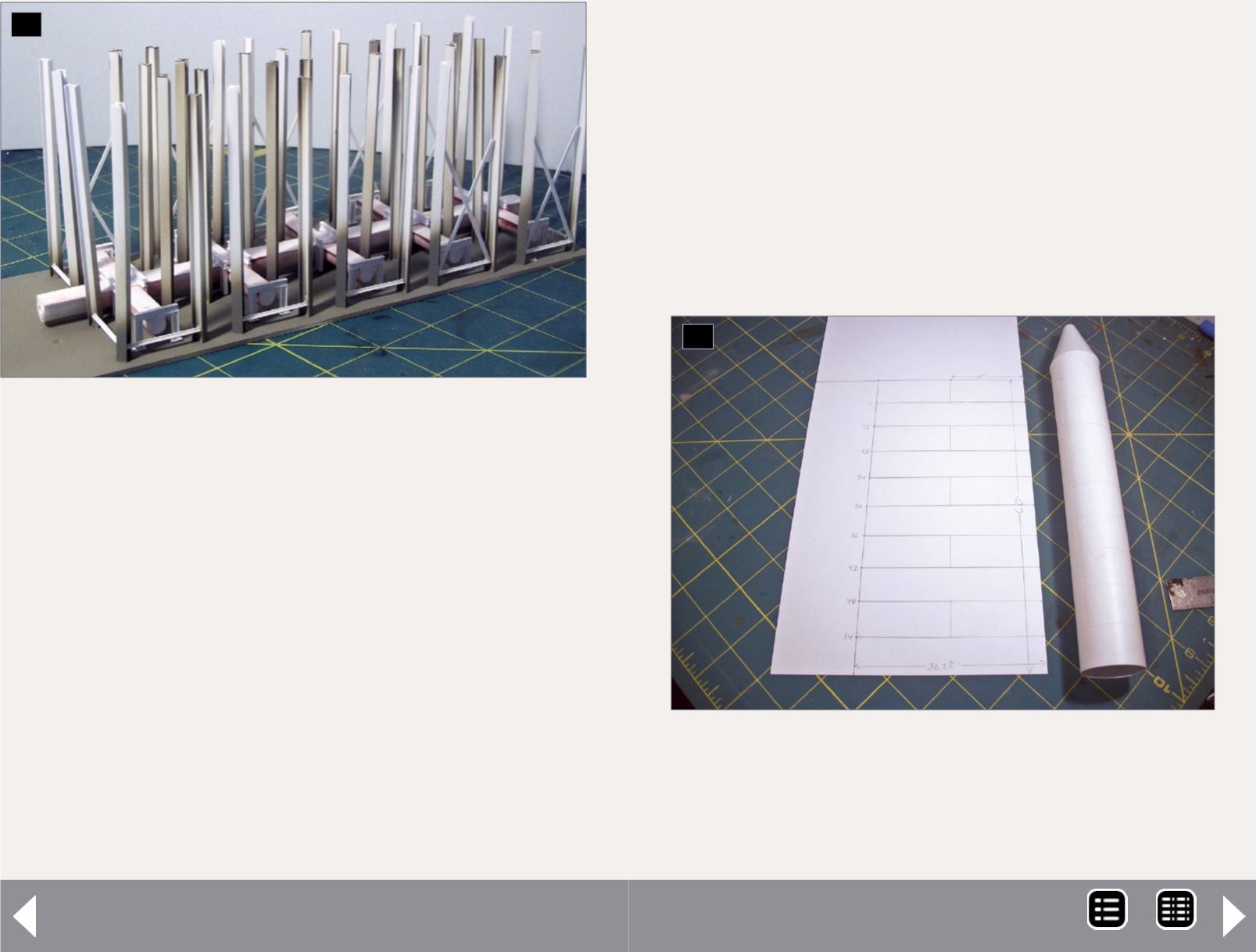

seams every six scale feet across the overall height of 60 scale

feet. Then I measured the vertical seams half the width of the

sheet, every 15.1 scale feet, skipping every other weld seam so

the joints wouldn’t overlap. The final step was to cut the width

of the sheet at 22.78 scale feet, which is the correct circumfer-

ence for the 1” PVC pipe.

Wrapping the styrene is a bit of a challenge, but as shown in

the photos it’s not as difficult as it looks, particularly if the seam

isn’t visible on the completed model (thereby not requiring any

sanding or filling). Finding suitable conical shapes for the silo

bottoms was accomplished by perusing the local Michael’s Craft

store cooking and cake decorating section. A company named

“Wilton” makes frosting application cones which were about the

20

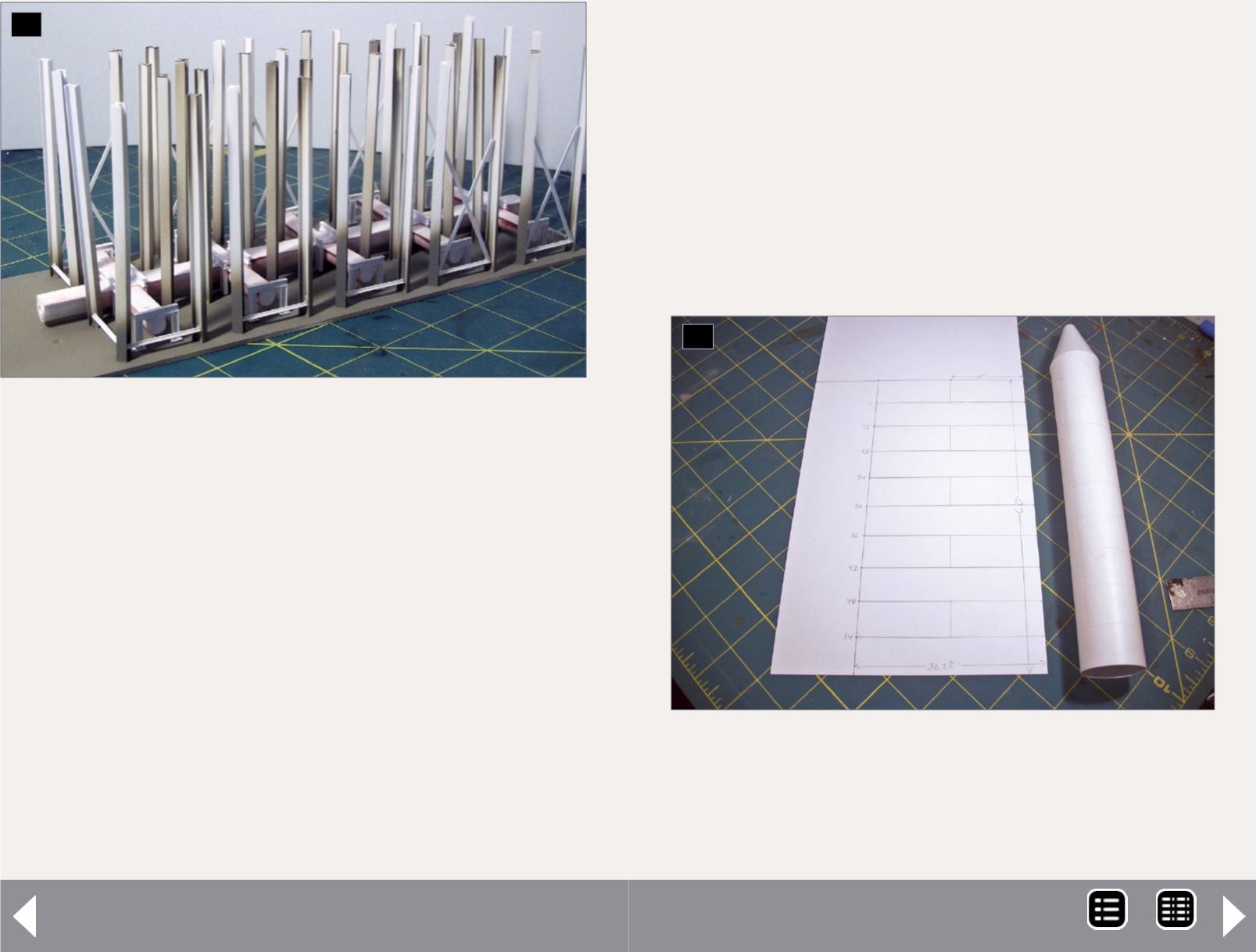

20. Partially completed silo base with auger installed

and some of the .020” by .060” diagonal bracing and

horizontal .060” angle glued in place between each

column support.

Agway Feed Mill - 11

right size and shape. Each of the cones required cutting the top

and bottom out to get the right 1” diameter at the top and cor-

rect 3/8” diameter at the tank bottom.

Once I had cut the cones to shape, I used ACC to glue the

cones to the PVC silos. The resulting seams weren’t perfect, so

I applied several coats of Bondo body putty to fill the seams.

Were I to do the silos over, I would have approached the con-

struction slightly differently by wrapping the styrene first, with

a slight overlap at the bottom of the PVC pipe, and glued the

21. This photos shows preparation of the .010” styrene

sheet to be wrapped around the PVC silo. The overall

size of the sheet is 60 scale feet tall by 30.25 scale feet

wide. Gently scribed lines every 6 scale feet represent

the weld seams of the silo.

21

MRH-Sep 2014