At the time of this article preparation, I’m still in the process

of finishing the layout room, so having a solid base gives me

a secure way to store the mill until it’s ready to be placed on

the layout.

The base itself is constructed of ¾” plywood with a piece

of ¼” luan glued to the plywood with carpenter’s glue and

several drywall screws. The luan acts much like a piece of

Homasote, since it’s a softer wood and accepts track spikes

much easier than plywood. The majority of the base was cov-

ered with asphalt. One method I’ve learned to easily recreate

asphalt is using a readily available brand of drywall spackling

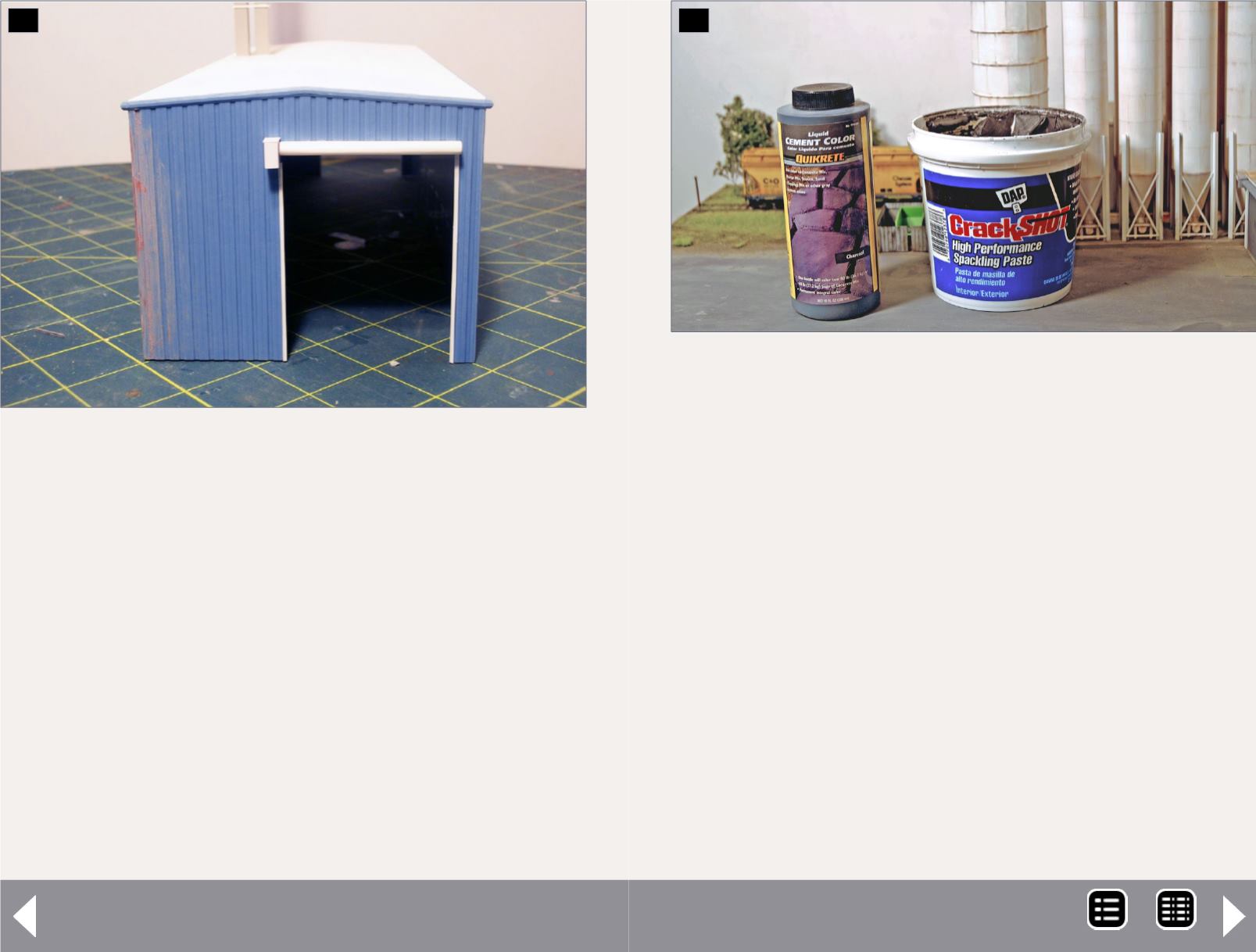

34. The car unloading shed was a straight forward

assembly of the Pikestuff Small Modern Engine House

with pieces of styrene used for the overhead door

assembly.

34

Agway Feed Mill - 17

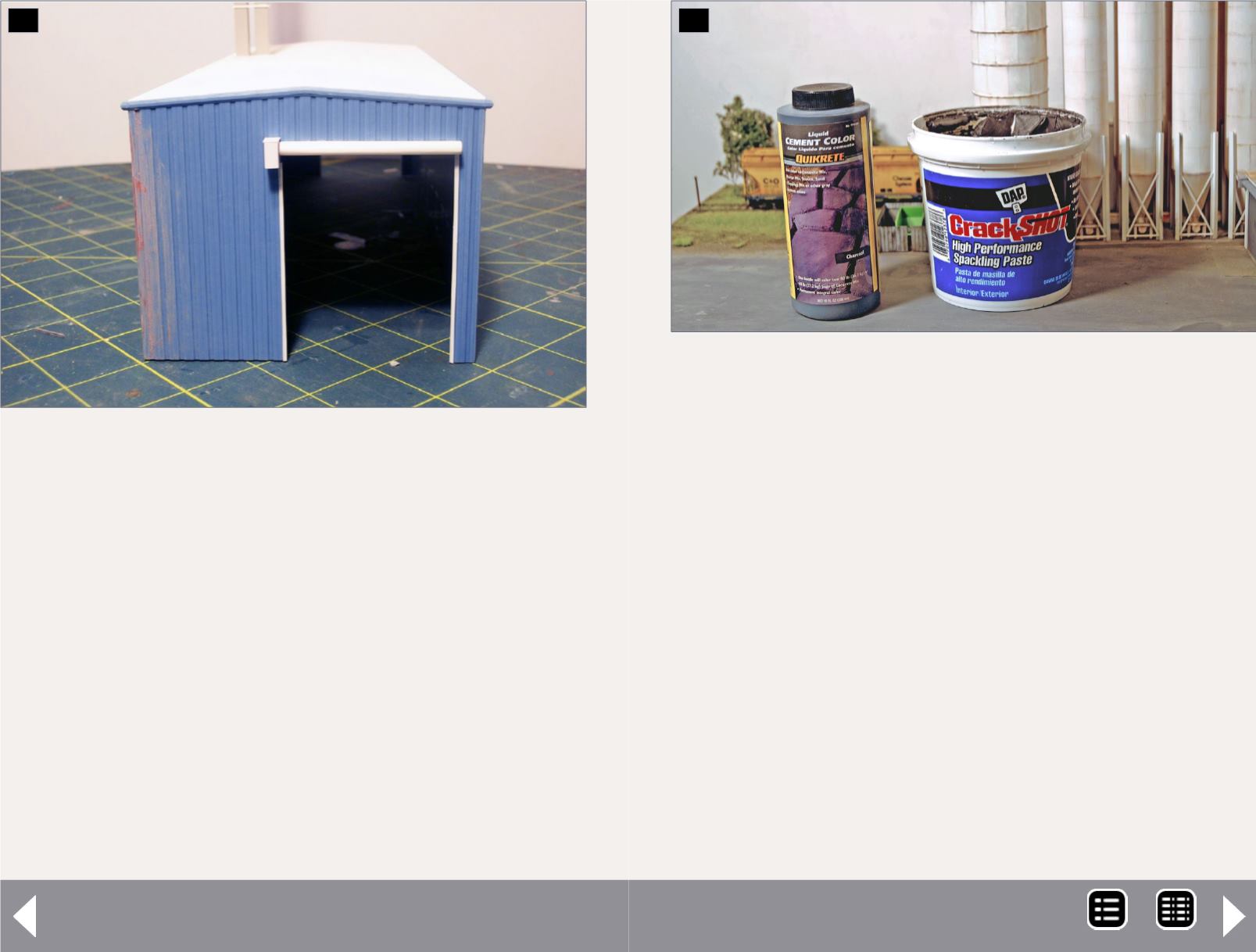

paste and adding cement coloring [35]. Once thoroughly

mixed, the spackling paste can be applied directly to the base

using a trowel.

As the spackle dries, I periodically use the trowel to smooth

the surface to remove the majority of the trowel marks. After

it dries, I use a wet cloth to smooth out the area. The benefit

of adding the coloring is if the spackle chips, the white color

doesn’t show through. If the coloring isn’t perfect, I paint on a

coat of 50/50 mix of Woodland Scenics concrete and asphalt

35. I’ve always used drywall spackling for creating

asphalt roads and parking lots, but the drawback was

always chipped or cracked surfaces that allowed the

white spackle to show through. One trick I discovered

a few years ago was commercial grade cement coloring

available at home improvement stores. The pigment

content is strong enough to darken the white spackle

very quickly and saves a step by not having to paint the

completed asphalt.

35

MRH-Sep 2014