Agway Feed Mill - 5

Machine Shop/Service Garage. The windows included in the kit

seemed to have the same general shape and with a little bit of

trimming I was able to create the correct mullion arrangement

[11-12].

After completing the door and windows, I made vents located

on the main structure walls from some Cannon & Company

Radiator Screens (part 141-1401). The vents were modified by

sanding them down to an approximate thickness of .030” and

gluing two of them to the east side wall and one to the north

side wall. Completing the main structure included personnel

railings along the roof and ladders with platforms on the out-

side of the building, but due to their fragile nature and added

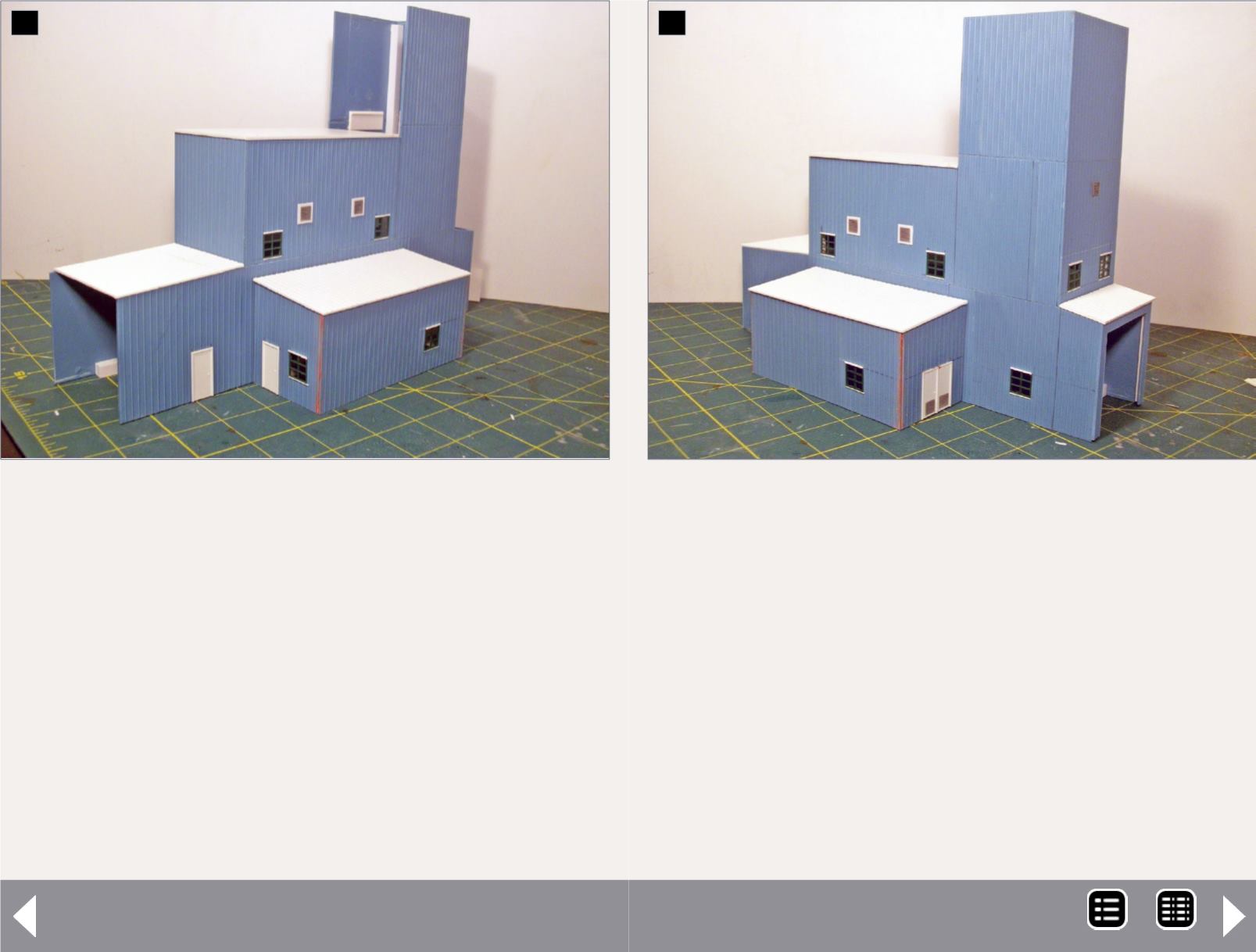

8. Assembled main structure including office addition,

viewed from the south.

8

handling required, I held off adding the Tichy railings and lad-

ders until the elevator and silos were completed. Once the

walls were built and window openings cut, I assembled each

wall with Evergreen .250” x .250” styrene at each corner for

bracing.

Feed bin

The Feed Bin was the most difficult part of the structure con-

struction, my delaying tactics before construction involved

thoroughly researching photographs for suitable scratchbuild-

ing supplies to achieve the desired look. As the prototype pho-

tos illustrate Bernardston Mill [4], the bin is constructed of

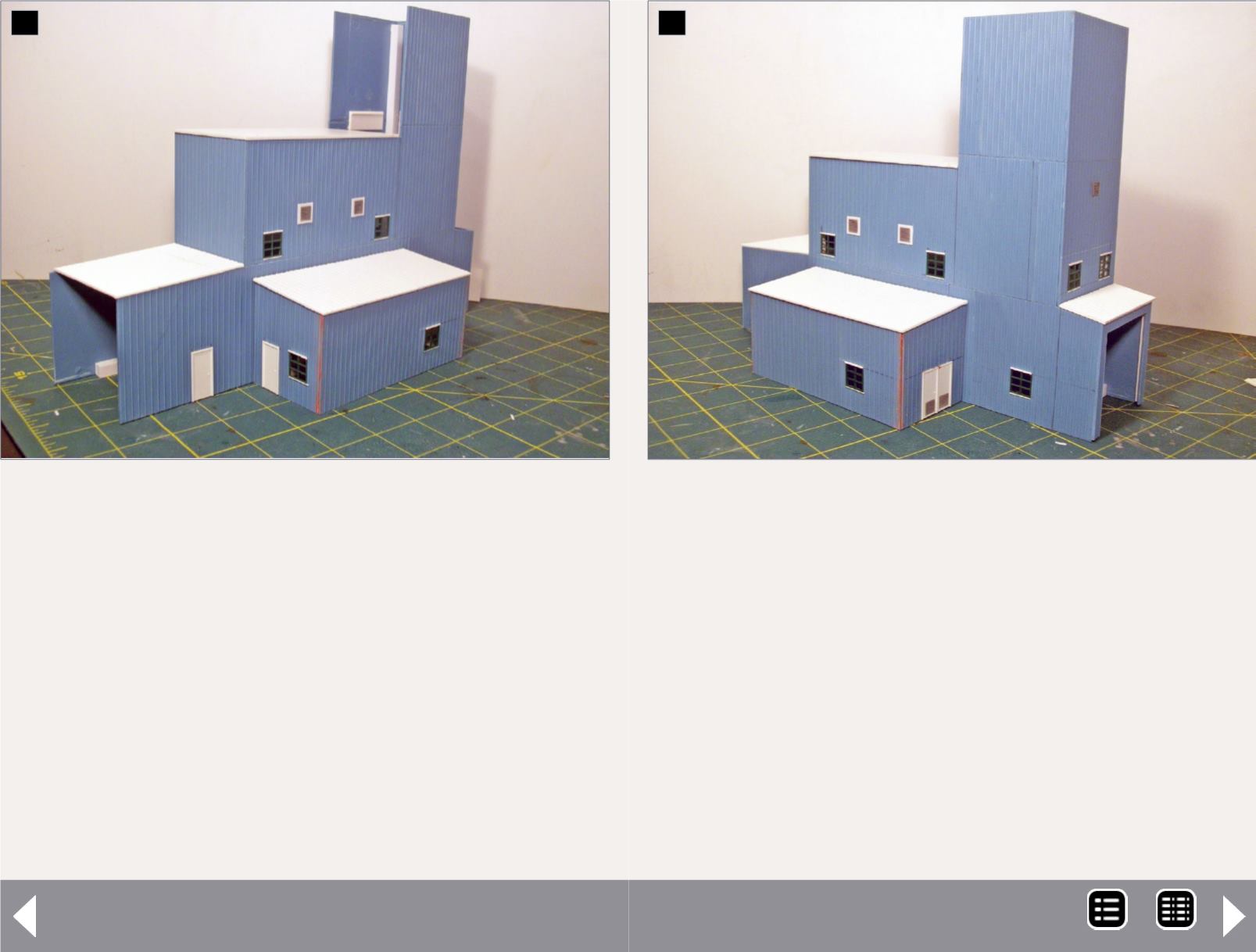

9. Assembled main structure including office addition,

viewed from the north.

9

MRH-Sep 2014