-

STEP 14: Final Assembly

43: The final construction, and painting.

44

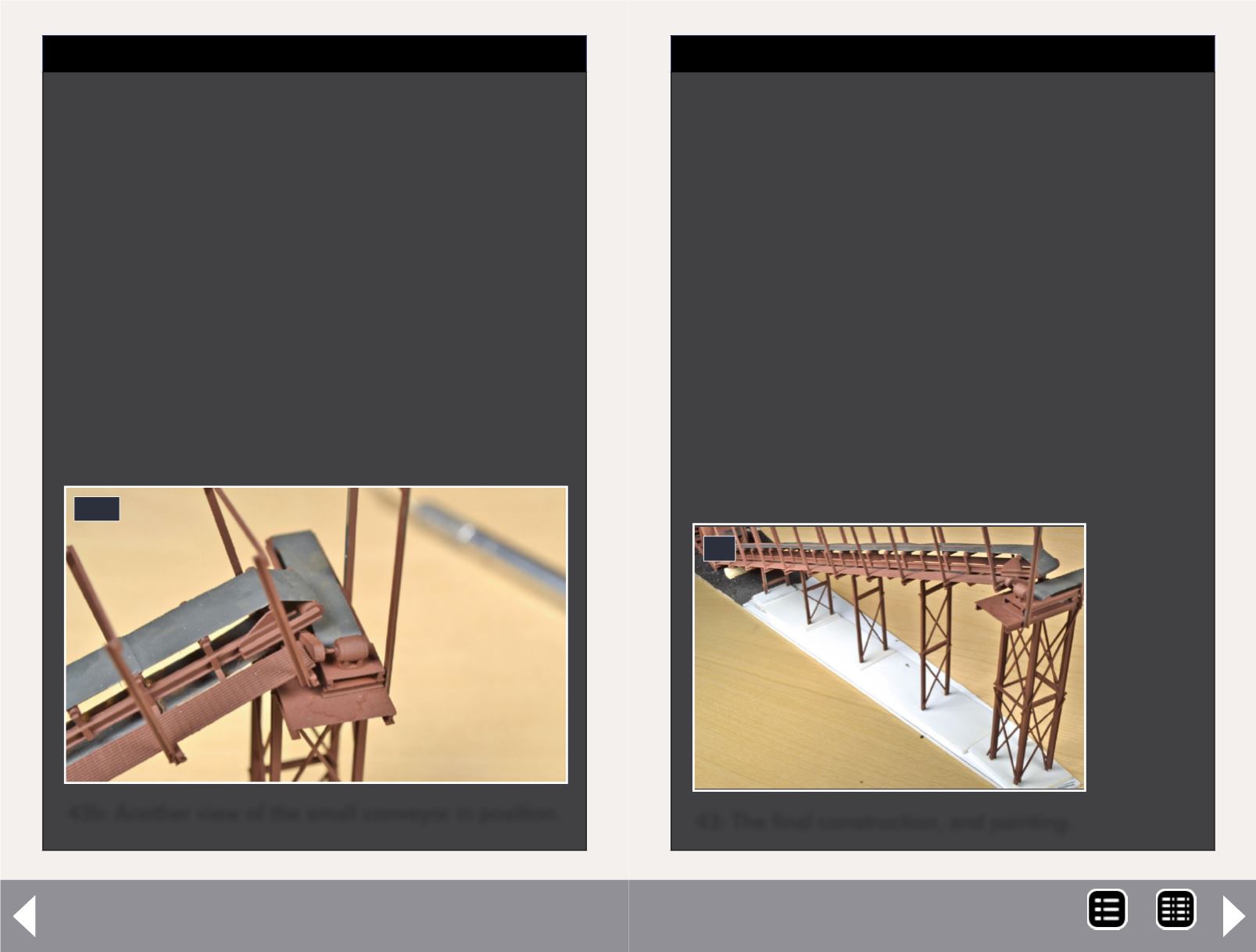

Prior to installing the siding and roofs, we’ll finish up construc-

tion of the conveyor. Set the large conveyor in place between

the breaker and the tower. Now position the small conveyor

so that the belt from the large conveyor extends slightly over

the top of the belt on the small conveyor.

Glue the small conveyor in place and then glue the large con-

veyor in place by brushing a small amount of liquid cement

between the I-beam supports and the bottom rails of the

large conveyor. Next, glue the 4 bents in place.

As you can see from the photo below, I had to shim 3 of the

support bents in order to get them in the right position. Use

small scraps of styrene for the shims.

Note that the receiving bin has not been glued in place yet-

we need to apply the siding to the back before this step. Once

the bents are in place, paint the surrounding styrene a grimy

black color.

Coal loader, p2 - 11

-

STEP 14: Final Assembly

Continued ...

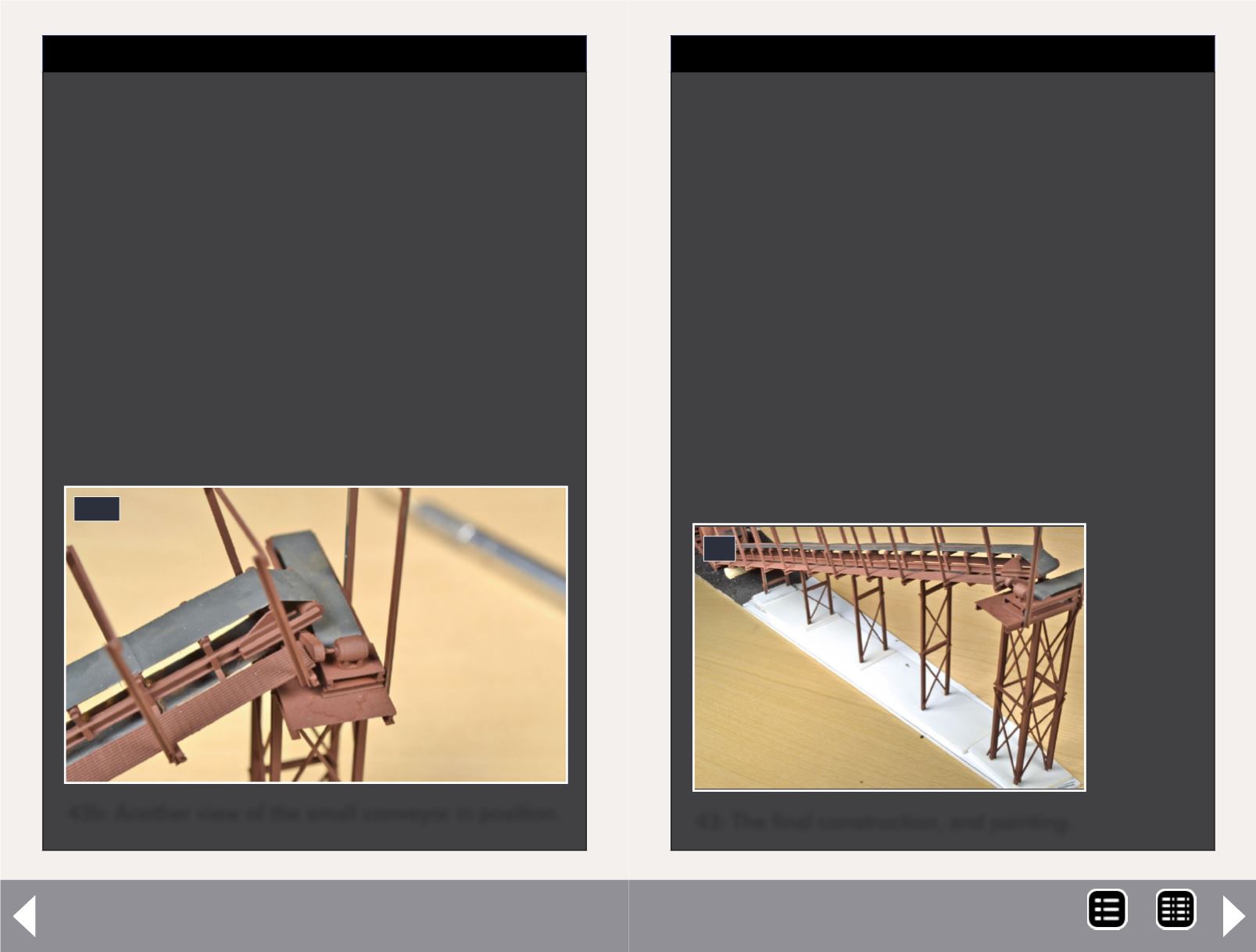

43b: Another view of the small conveyor in position.

43b

box. The belt cover is a piece of .060 styrene filed and

sanded to shape. Next, cut a piece of .060 I-beam to the

width between the channels and glue it at the end of the

channels under the platform.

Cut two small pieces of .060 I-beam and glue them parallel to

the bottoms of each channel approximately 3’ from the end

of the conveyor away from the motor.

Paint this assembly with the same rust color used previously.

When the paint is dry, make the belt from a strip of masking

tape and paint it a grimy black color.

Photos 43a and 43b show the small conveyor in position at

the top end of the tower.

MRH-Jan 2013