-

STEP 11: Preparing the Assembly Base

Continued ...

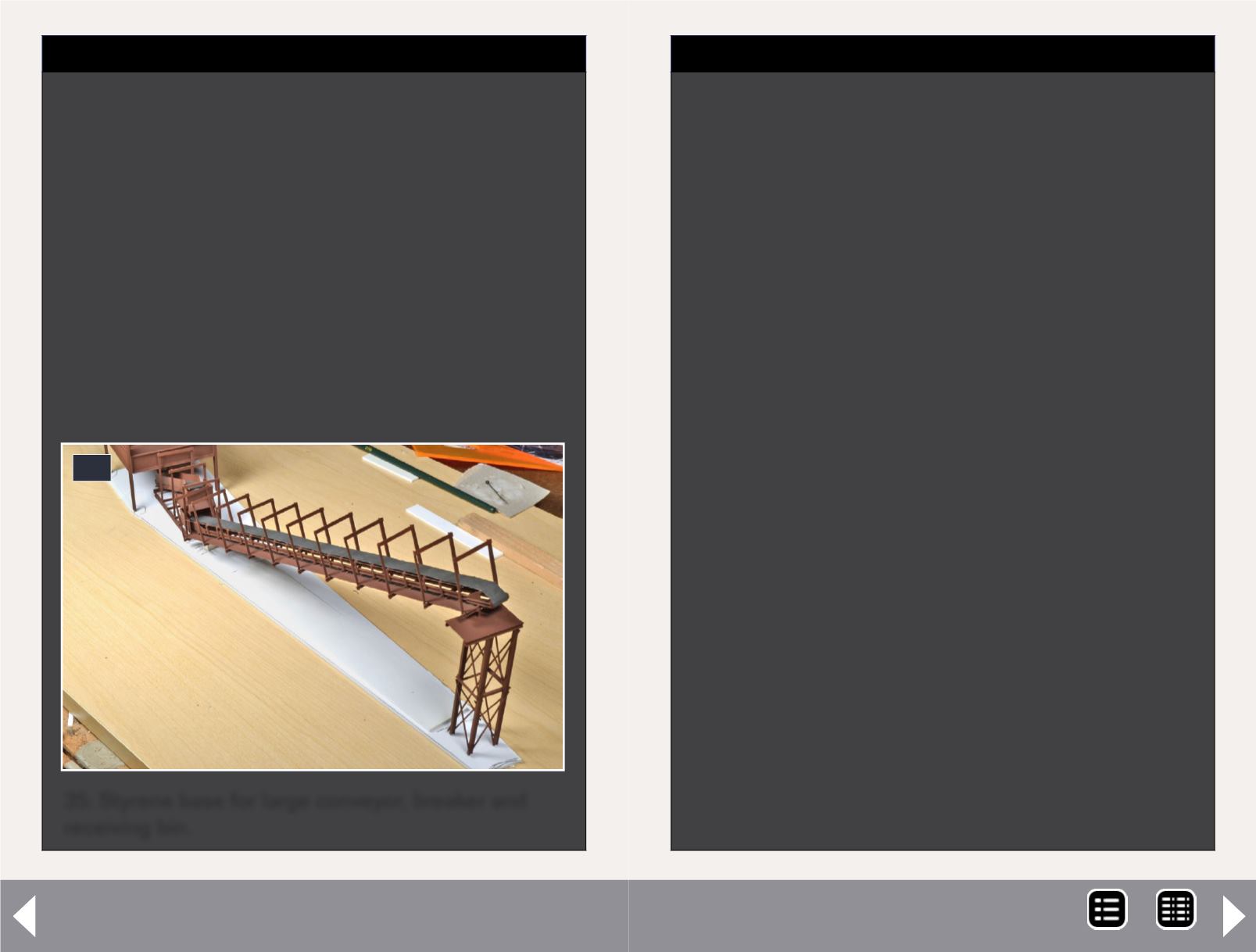

5” piece of .060 styrene for the base. Position the receiving

bin, breaker, conveyor and conveyor tower on the base and

then mark the areas outside of the basic structure. Cut these

away and you’ll have a base that looks like the one in the

photo above.

I realized at this point that I would need to add the ground

cover under the breaker and the receiving bin prior to glu-

ing them to the base. And before I could add the ground

cover, I needed to install some base supports for the breaker

and the large conveyor. In the photo here (35), the breaker

is resting on two lengths of .040 x .040 styrene cut to the

width of the structure and glued to the base at either end.

In order to elevate the large conveyor so that it would rest

inside the breaker, I cut a piece of hydrocal from a retaining

wall that I had left over from another project and glued it in

place with epoxy. As a result of raising the end of the large

conveyor at the breaker, the support bents for the conveyor

were now too short.

I added a piece of .060 styrene to the styrene base along the

length of the conveyor as shown in the photo here (35) in

order to solve this problem.

-

STEP 11: Preparing the Assembly Base

At this point in the project, I thought the next step would

be to construct the roofs for the breaker and the conveyor

and put together the sides and roof for the receiving bin.

As I began to take measurements for the roof of the large

conveyor, I realized the part of the roof would extend over

the tower at the end of the conveyor. And the end support

for the roof would be attached to the tower.

Therefore, there was no way to accurately measure the

length of the roof without having the conveyor and the

tower glued in place. So the next step became building

the base so that the breaker, conveyor and tower could be

glued in place prior to constructing the roofs.

In order to make sure that all of the various pieces fit

together correctly and to provide some support, cut a 13” x

35: Styrene base for large conveyor, breaker and

receiving bin.

35

Coal loader, p2 - 5

MRH-Jan 2013