-

STEP 10: The Receiving Ramp

Continued ...

The remaining bents are spaced 5’ apart as shown on the

profile drawing shown in Drawing 6.

Measure the height of the next bent, make a horizontal

line at this height across the bottom of the bent template,

and cut the cap and posts to fit. The cap should be the

same 15’ width for each of the bents. Follow this proce-

dure for the next 3 bents and apply cross bracing using 2’

x 6’ pieces as outlined above. The cross bracing is omitted

on the next five bents.

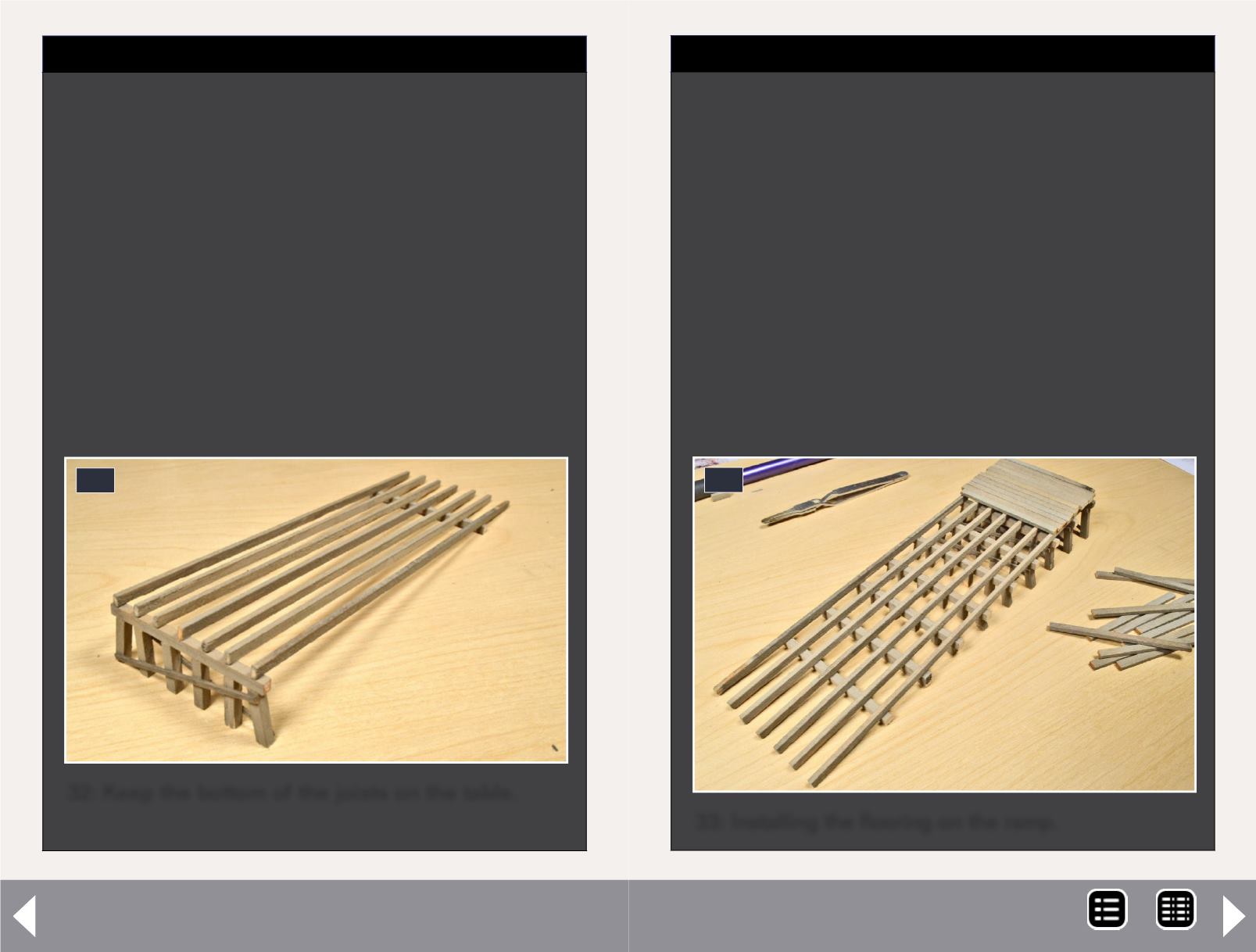

The support between the single piece of 12” x 12” and

the last bent is two pieces of 12” x 12” glued together and

sanded to fit under the joists. Next, cut the flooring from 4”

x 10” basswood.

33: Installing the flooring on the ramp.

33

-

STEP 10: The Receiving Ramp

Continued ...

Once the posts have dried on the first bent, cut two pieces

of 2” x 6” to a length of 14’ for the cross bracing. Glue them

in place as shown in the photo above. Next, cut 7 floor joists

from 4” x 12” basswood to a length of 50 scale feet. Make a

mark 6” in from each end of the bent and glue a joist flush

with this mark.

Glue the remaining joists in place spaced equidistant from

the outer two joists. Cut a piece of 12” x 12” to a length of

15’ and glue it in place by sliding it under the joists until

it makes contact with the bottom of the joists at the end

opposite of the bent.

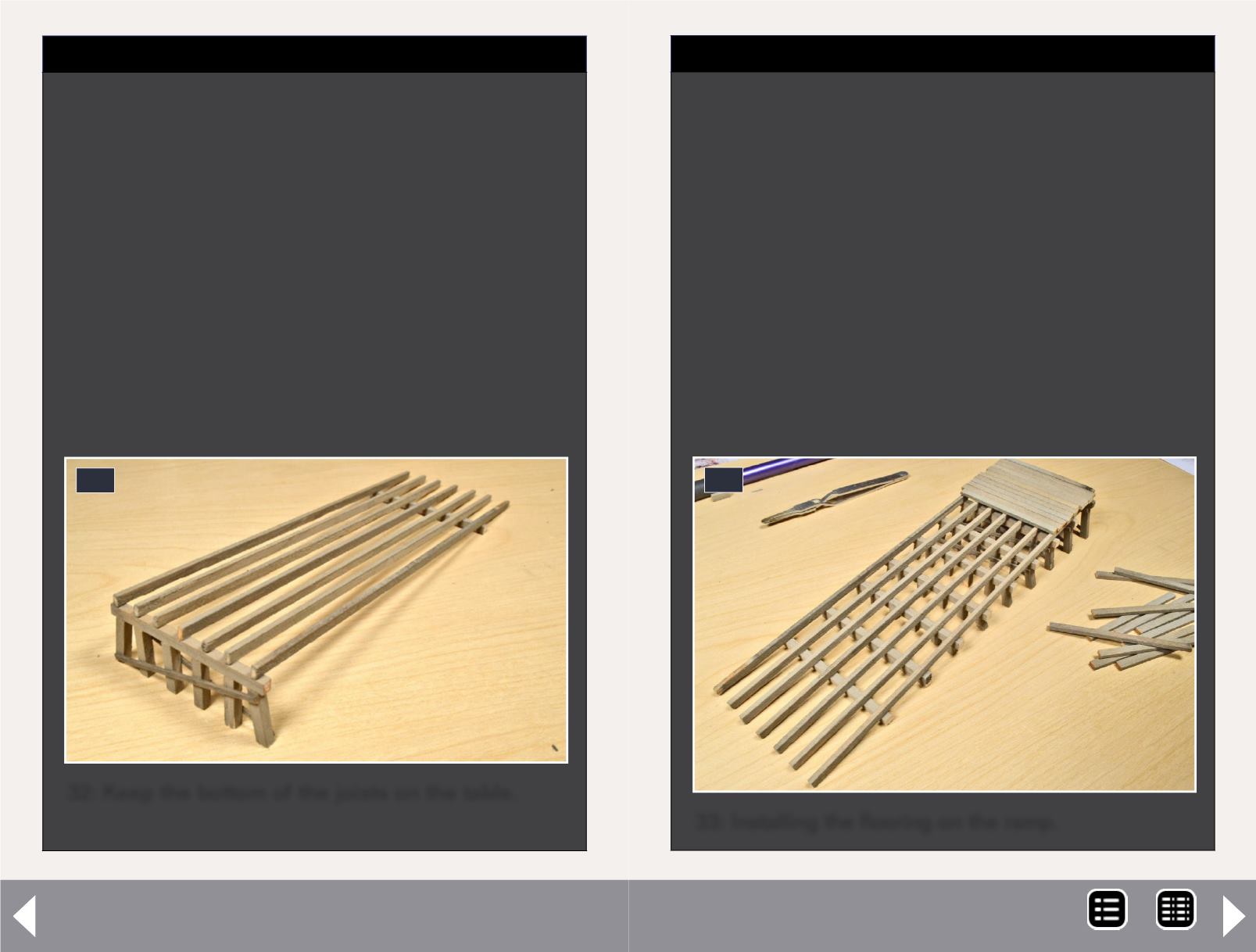

The bottom of the joists at this end should remain in contact

with the work surface. The photo here (32) shows how the

ramp should appear at this point.

32: Keep the bottom of the joists on the table.

32

Coal loader, p2 - 3

MRH-Jan 2013