-

STEP 14: Final Assembly

Continued ...

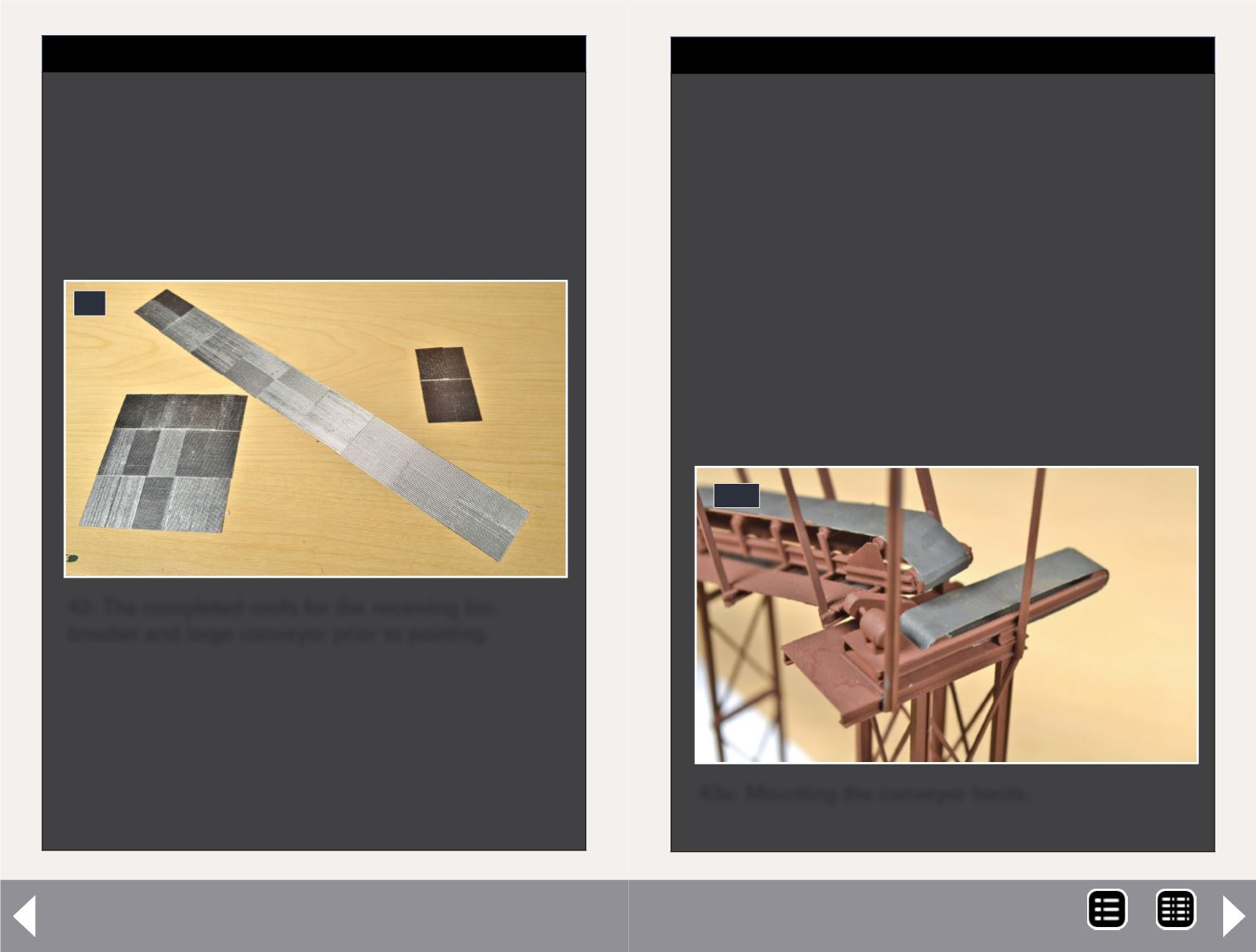

To build the small conveyor that sits at the top of the

tower, start by cutting two pieces of 3/64” channel to a

length of 10 scale feet. For the rollers, cut two 2’ pieces if

1/8” styrene tube. Glue the first piece to the end of one

of the pieces of channel and glue the second one 2 1/2’ in

from the other end- see the photo above for the location

of the various pieces.

Next, glue the other piece of channel to the other side of the

pieces of 1/8” tube. The rollers should be centered on the

channel pieces. For the platform for the motor, cut a piece of

.010 sheet styrene to the width between the channels and a

length of 1 3/4 scale feet and glue it the end of the channels

away from the rollers (described on next page).

The electric motor (see 43a) is from Williams Brothers but

you could substitute something similar from your scrap

43a: Mounting the conveyor bents.

43a

-

STEP 13: Apply Corrugated Siding

Continued ...

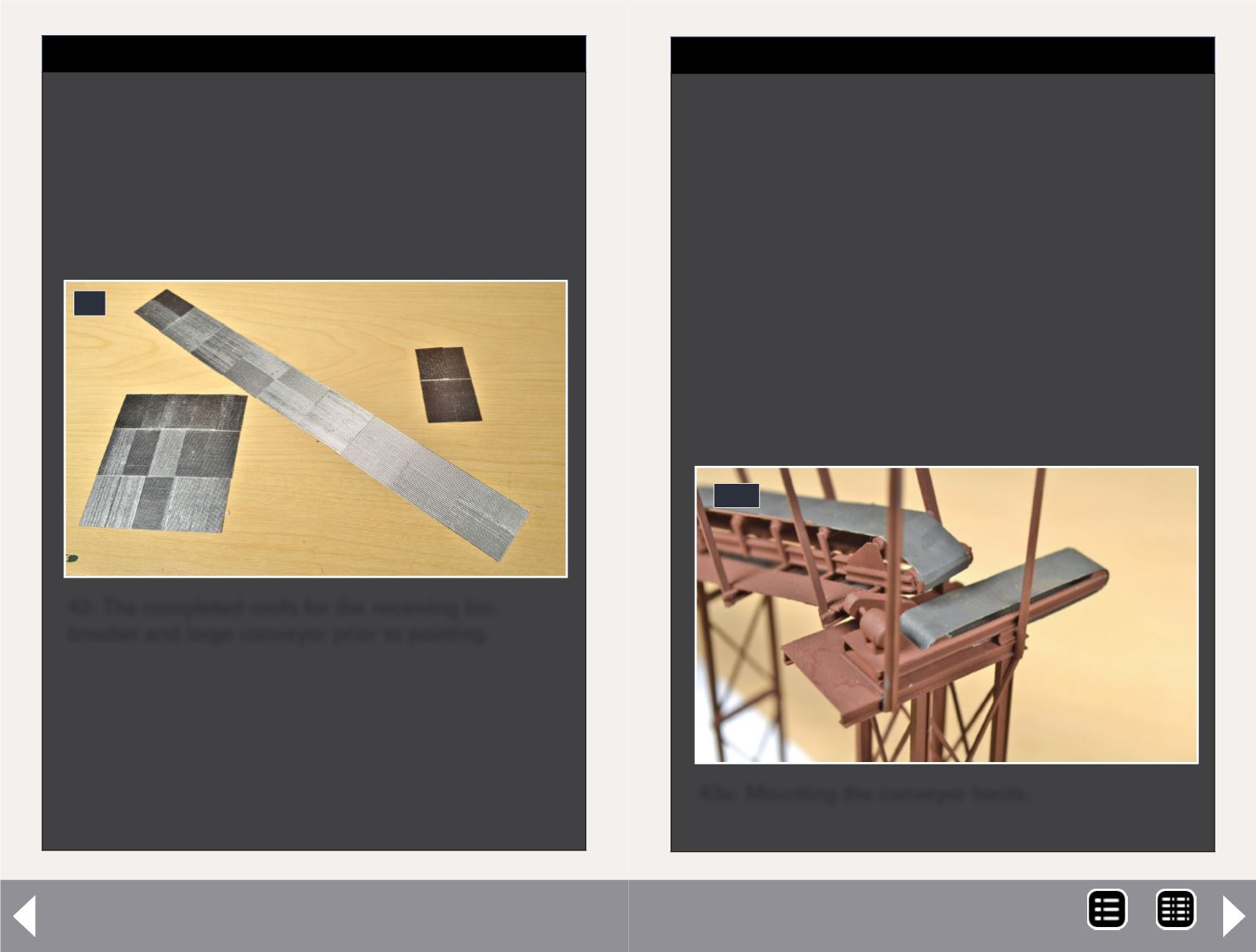

42: The completed roofs for the receiving bin,

breaker and large conveyor prior to painting.

42

masking tape. Once the first side of each piece is dry, flip

them over and paint the other side.

Once the paint had cured, apply a spray of Testor’s Dullcote to

each side. The last step is to weather each piece on both sides

using your favorite weathering techniques. For this step I used

artist’s oils and paint thinner, applying the colors in washes.

Coal loader, p2 - 10

MRH-Jan 2013