-

STEP 10: The Receiving Ramp

Continued ...

I also stippled on some of this stain in the center of the

ramp to represent oil and grease from the constant stream

of dump trucks backing up to unload coal. We’ll add some

additional weathering later.

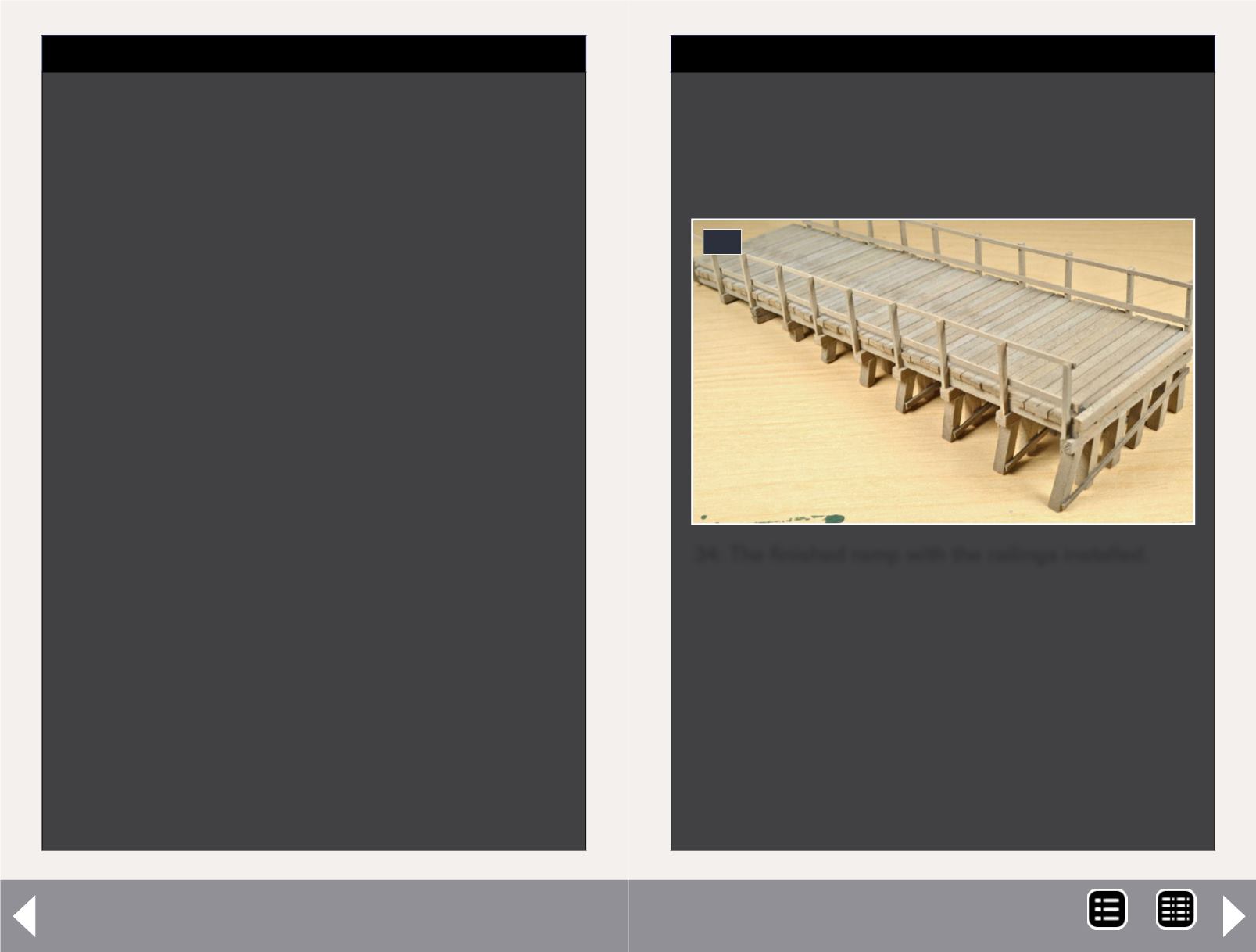

34: The finished ramp with the railings installed.

34

-

STEP 10: The Receiving Ramp

Continued ...

I used a Northwest Shortline Chopper for the various

pieces of scale lumber and set the stopper at a distance

of 14 3/4’ from the blade. I varied the length of the floor

boards by cutting various pieces slightly shorter than 14

3/4’. The first board at the top should be cut equal to the

distance between the joists. This piece will be placed over

the top of the bent, and we need to leave room to glue the

railing posts.

The floor pieces at each of the bent tops should be cut in

a similar fashion. The photo here (33) shows the flooring

being installed. Note the floor boards at the tops of the first

three bents- each has been cut flush with the edge of the

floor joists as described above (33).

Installing the railings will finish the ramp part of the project.

For the posts, cut 20 pieces of 4” x 6” to a length of 5 1/2’

and glue them to the top of each bent. The lower railing is

a piece of 2” x 6” and the upper railing is a piece of 2” x 4”.

Cut both pieces slightly longer than the distance between

the posts at each end and glue them in place.

Photo 34 shows the completed ramp with the railings in

place. Don’t forget to touch up the unstained ends of the

basswood. I used the same black stain used earlier but

diluted it about 50/50 stain to water. I used a small brush

and lightly touched each end in order to avoid getting too

much stain around the ends of the pieces.

Coal loader, p2 - 4

MRH-Jan 2013