-

STEP 11: Preparing the Assembly Base

Continued ...

enough roomwhere the large conveyor meets the breaker for

the roof of the large conveyor to extend in under the breaker

roof. Once you are satisfied with the position of the conveyor

and tower, glue the tower to the base.

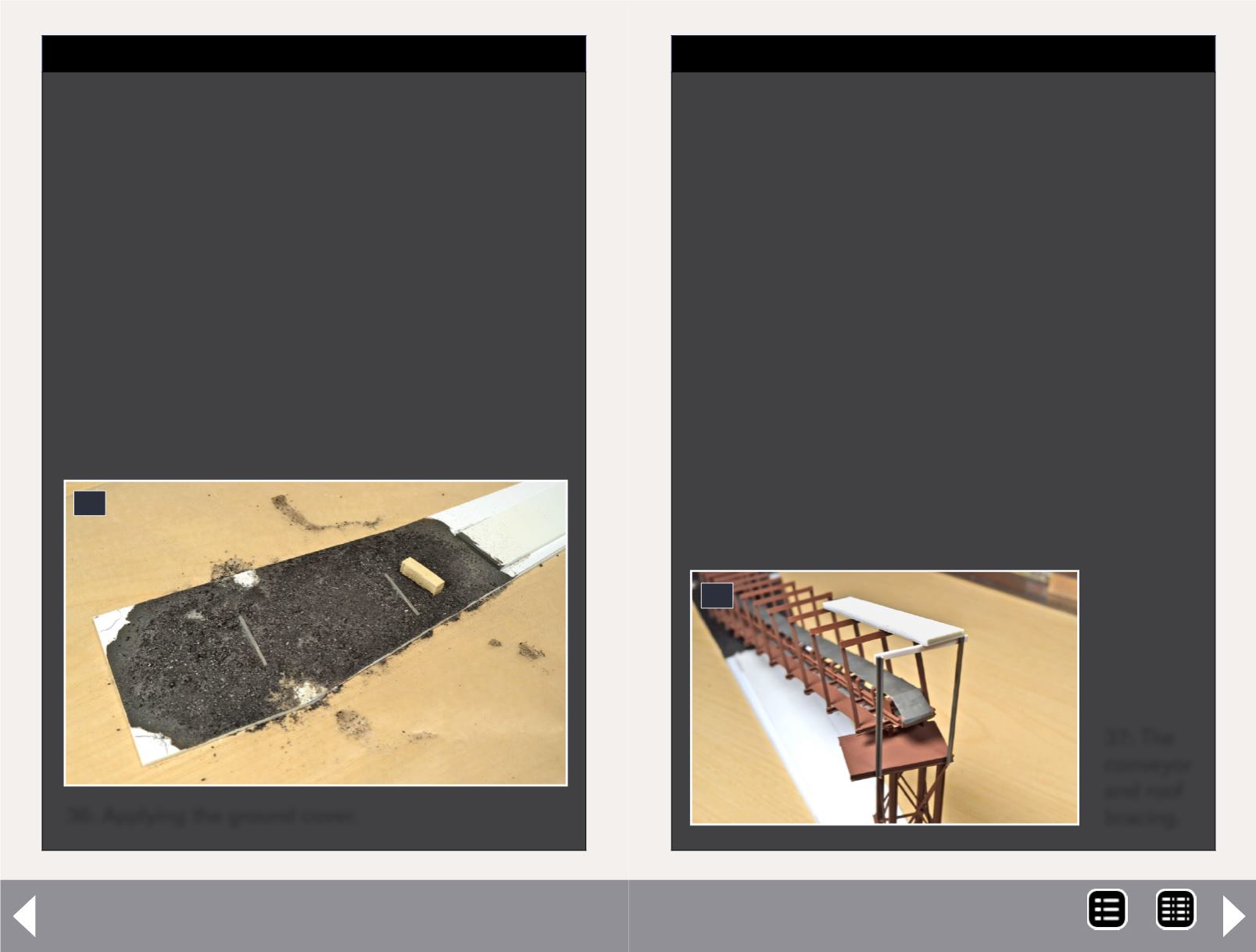

At this point I placed a small strip of .060 styrene on top of the

last two roof brackets at the conveyor end and let it extend

over the tower- see the photo above. Be sure that the con-

veyor is placed in the right location, both on the tower and at

the base. If it isn’t, the measurement for the height of the end

brackets will be incorrect.

For the end roof brackets, measure the distance from the

edge of the tower to the bottom of the piece of .060 styrene

and cut two pieces of 3/64” angle to this length. Glue them in

place as shown in the photo. Cut a piece of scale 2 x 6 to the

width between the two angles, glue it in place and paint the

angles and cross brace with the rust color used previously.

Now that this last piece of the roof bracing is in place, we can

measure the full length of the roof for the large conveyor.

37

37: The

conveyor

and roof

bracing.

-

STEP 11: Preparing the Assembly Base

Continued ...

Prior to applying the ground cover, I painted the area with

PollyScale Grimy Black. For the ground cover, I used Highball

Products N-Scale black ballast followed by coal dust and some

Highball Egg Coal (3”- 5”). I soaked the area with 70% isopro-

pyl alcohol and then applied a 2:1 mix of wet water (1 tea-

spoon of detergent to 16 ounces of water) and white glue.

Note in the photo here (36) that I kept the ground cover

away from the areas where the legs for the receiving bin will

be glued to the base. I also covered the work surface with a

piece of wax paper to protect it from the glue and water.

Once the ground cover is dry, glue the breaker in place on the

two pieces of .040 x .040 styrene.

Next, set the tower in place and carefully place the large con-

veyor between the tower and the breaker. Be sure to leave

36: Applying the ground cover.

36

Coal loader, p2 - 6

MRH-Jan 2013