Build your first resin car - 5

associated piping. If you are unsure of how all of these parts

go together, there is an excellent article by Ted Culotta in his

Essential Freight Car Series in the August and September 2003

issues of

Railroad Model Craftsman

that shows both AB brake

and K brake assembly.

Drill the holes for all of the brake lines while the parts are still

on the sprue. They will not be accessible after the underframe

is assembled. Use a size 78 drill and have at it. There are two

holes in the reservoir and four in the triple valve.

The brake cylinder has one hole, in the rear. Also at this time, it

is best to drill out the holes in the brake levers. The wire piping

between the reservoir and the triple valve is .012”, between

the triple valve and the cylinder is .010”, between the triple

valve and the train line is .010”.

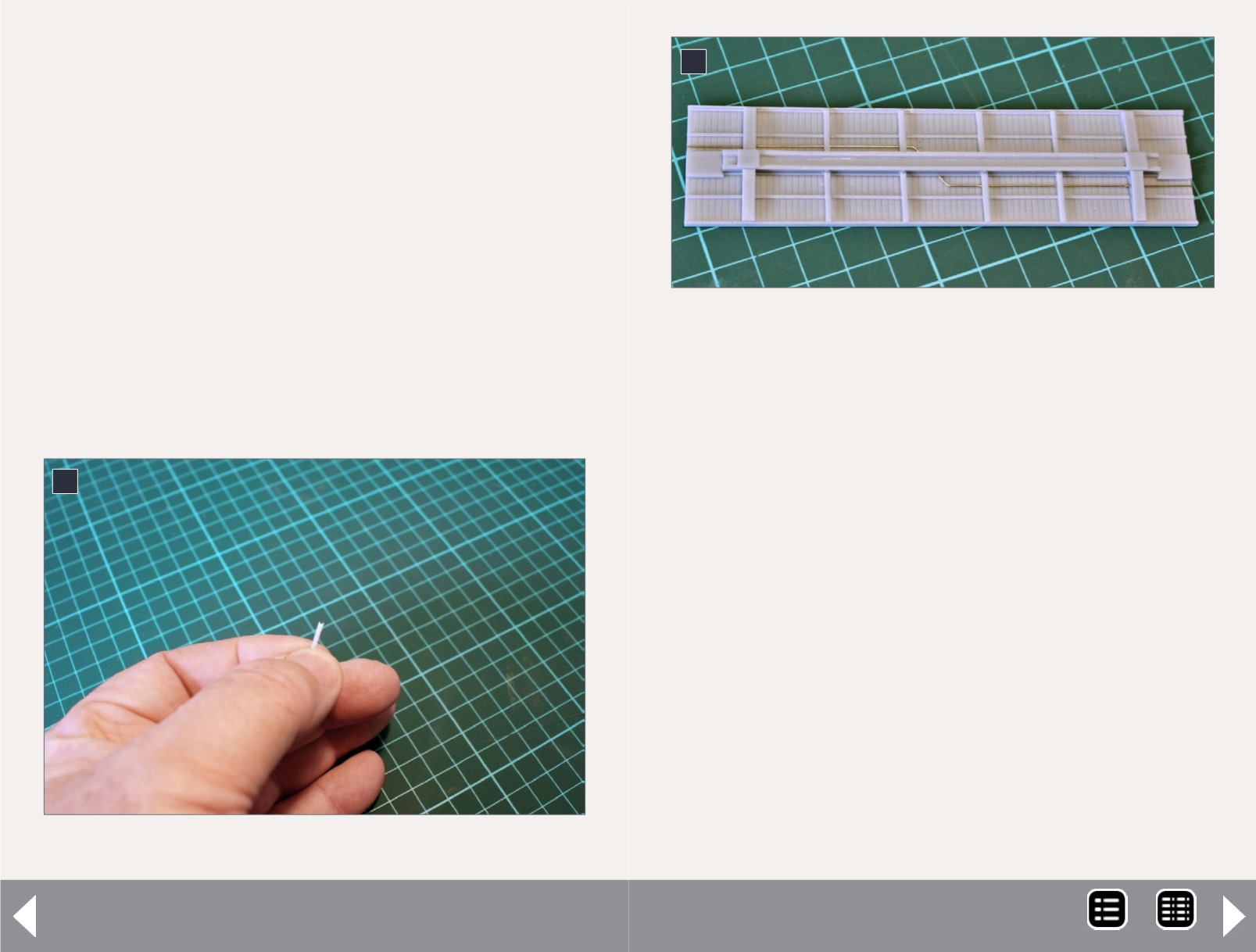

8. The stringer ready to be installed.

8

Finish the underframe

While the Sunshine instructions do not call for it, I also add

short lengths of chain between the cylinder and the cylinder

actuating brake line from the handbrake.

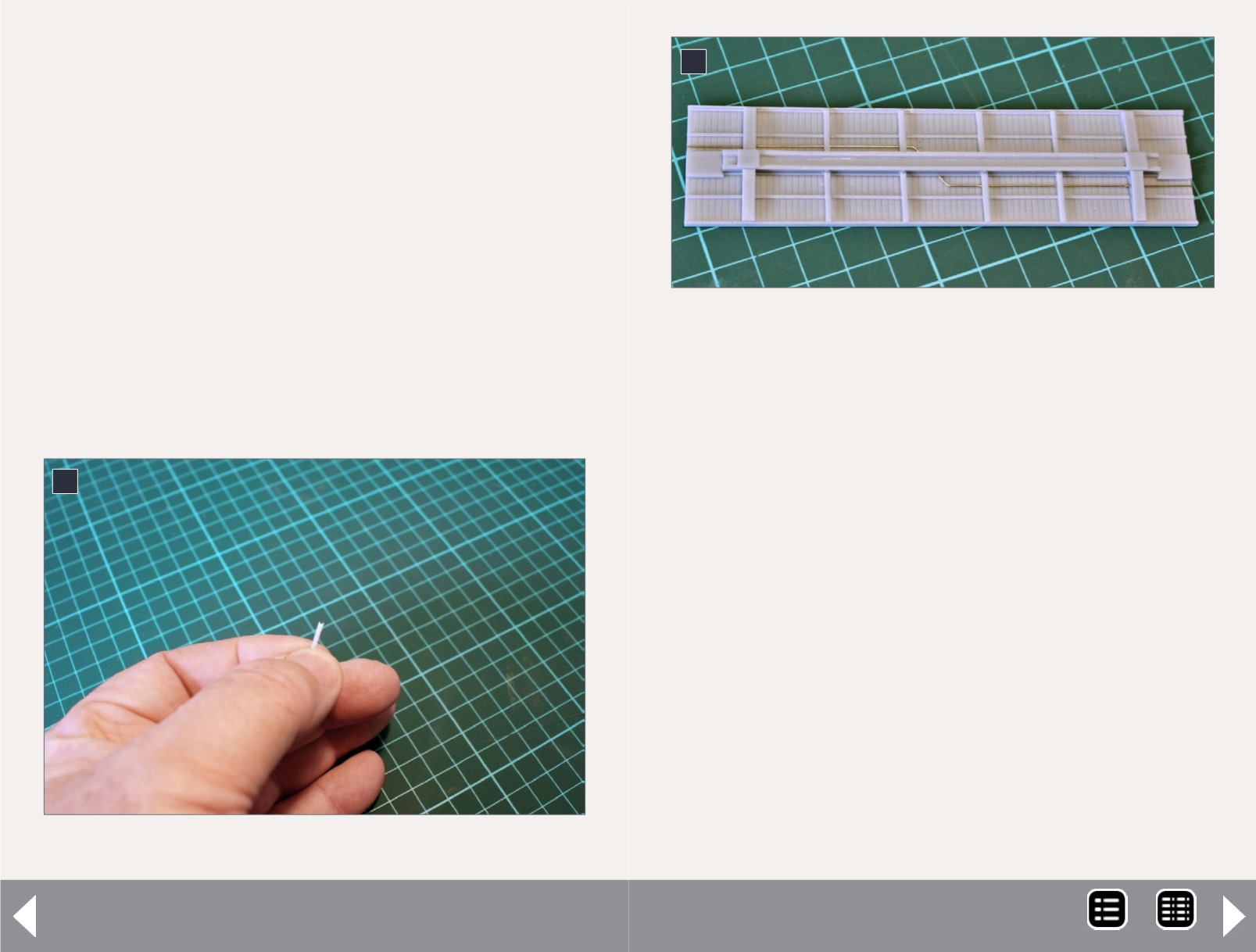

The easiest way to do this is to open up the end of an eye bolt,

slip the chain over it, and close the eye with pliers. Don’t try to

put it on the eye end. You’ll go blind trying. I take the long end

and thread it through the chain link just like threading a nee-

dle. The other end is some .012” brass wire with a small loop

bent into it, then threaded on the same way. It is easier to do

[9] than to describe.

To get this line in the underframe, I drill a number 76 hole

through the bolster. I make a small inverted “U” holder from

.012” brass wire, and place it over the line. Alternatively you

can mount the line on the bolster with another eye bolt. I pre-

fer to keep it away from the truck swing and mount the line

through the bolster itself. It may not be prototypical, but at

9

9. The underframe with the train line and stringers

installed.

MRH-Aug 2014