Build your first resin car - 6

least it is there and not interfering with operation. Add all of

the brake piping according to the diagrams in the kit. The brake

levers have to be supported by brackets made with grab irons.

TIP:

Before drilling the holes, cut one of the grab iron legs off

a bit shorter than the other, but long enough to insert. Drill

a hole for one side of the grab and then see where the other

end falls. Mark this position with a pin or needle and drill. This

procedure gets the distance right every time. Thanks to fel-

low freight car modeler Clark Propst for this tip. He has used it

on a number of occasions to add car pulling eyes to the sides

of freight cars. The idea works just as well for grab irons and

loops. The completed underframe with the brake assembly is

shown in [10].

Sides and ends

With the underframe done, it is time to start on the ends and

sides. First, add the grab irons to both ends. To help with drill-

ing the holes, I mark the location with a pin to act as a center-

ing point, stopping the bit from wandering and spoiling the

part. Again, cut one side of the grab iron short and drill one

hole, then line it up with the nut-bolt-washer (NBW) casting on

the other side.

If it fits, go ahead and drill and mount the grab iron. If it

doesn’t fit, you will have to shorten or lengthen the existing

grab iron, or make another from wire. Once drilled, insert the

grab irons and attach them with CA from behind. After the

glue sets, nip off the protruding ends. In [12] you can see both

ends with the grabs. I use the .020” styrene spacer to set the

grab irons the right distance from the end and sides of the car.

Finish the ends with the ladders, trim them to fit, and add the

brake details to the B end.

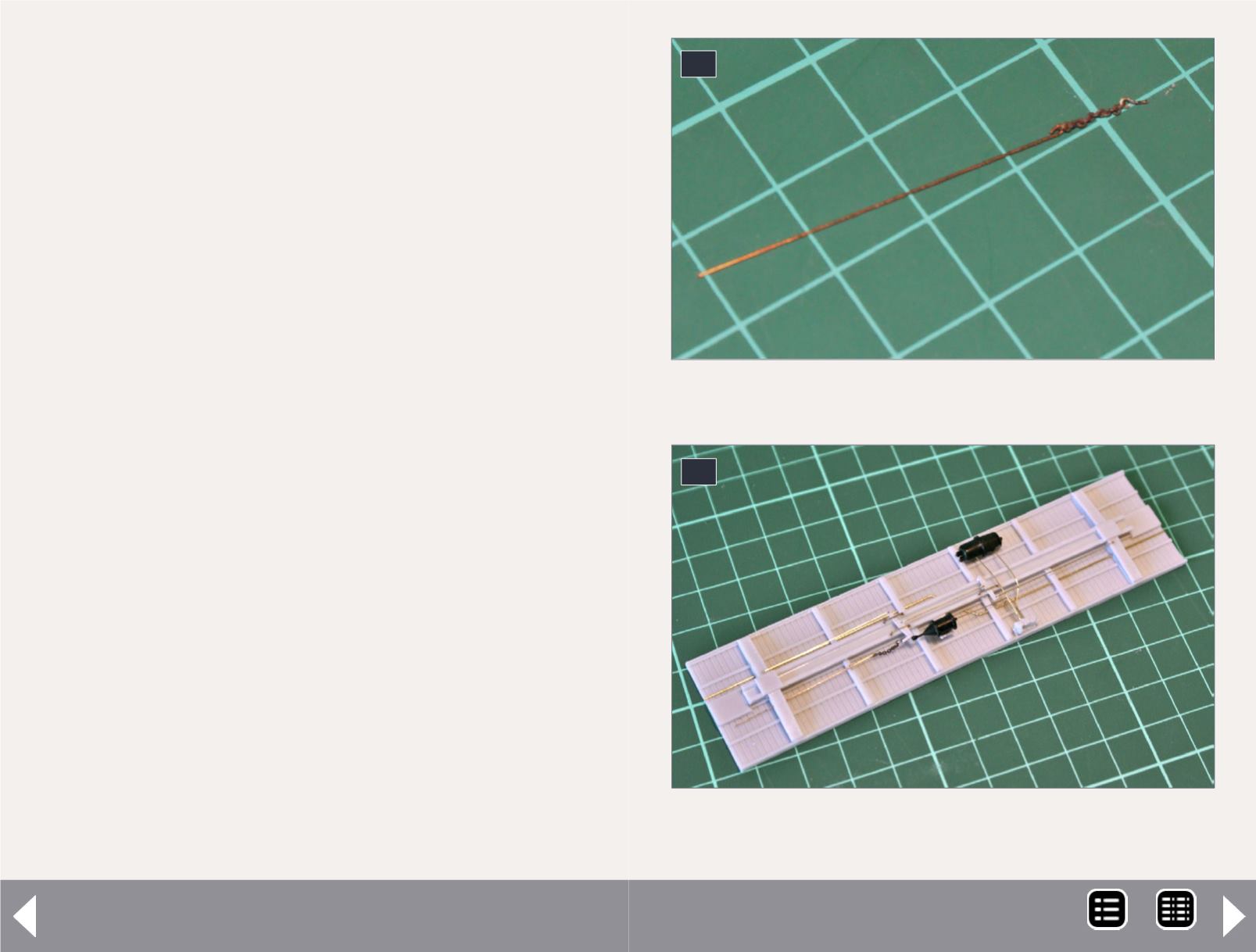

10

10. Chain attached to brake line.

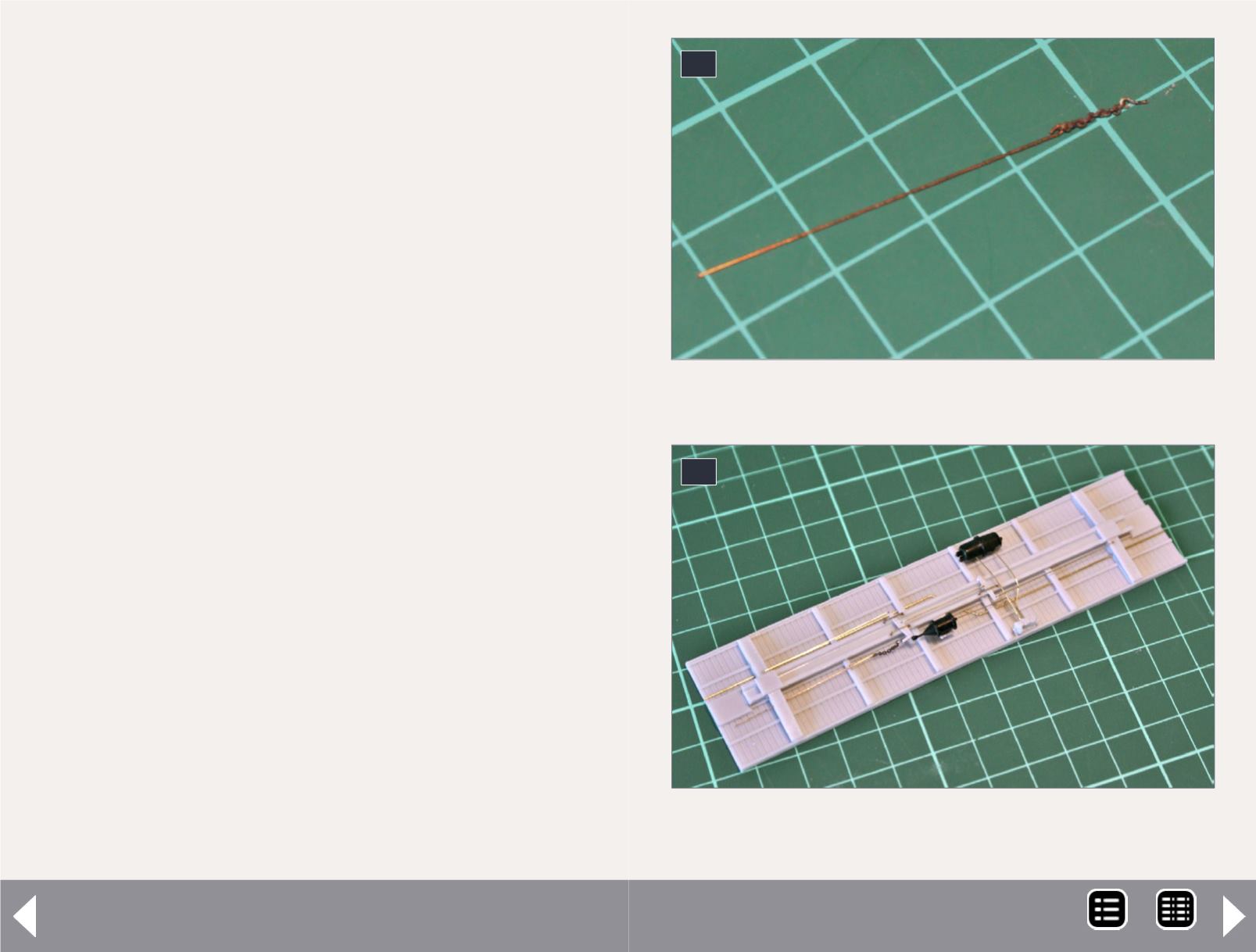

11

11. The brake valve, reservoir and brake cylinder with

piping installed.

MRH-Aug 2014