How to assemble the kit

Before starting assembly, check the sides for length and height.

They should match exactly. Mine were the same height but not

the same length. I carefully sanded the longer side until the

two sides were the same length. It is essential that the ends

and sides match each other. If they don’t, the model will be out

of square and the underframe or the roof will not fit without

gaps. Resin can sometimes shrink in the molding process and it

is not unusual for parts to be different sizes.

Now it is time to do some assembly. Read the instructions

before starting. Sometimes there are hidden treasures for you

to find. Familiarize yourself with the assembly sequence. For

this kit, after reading the instructions I changed the sequence.

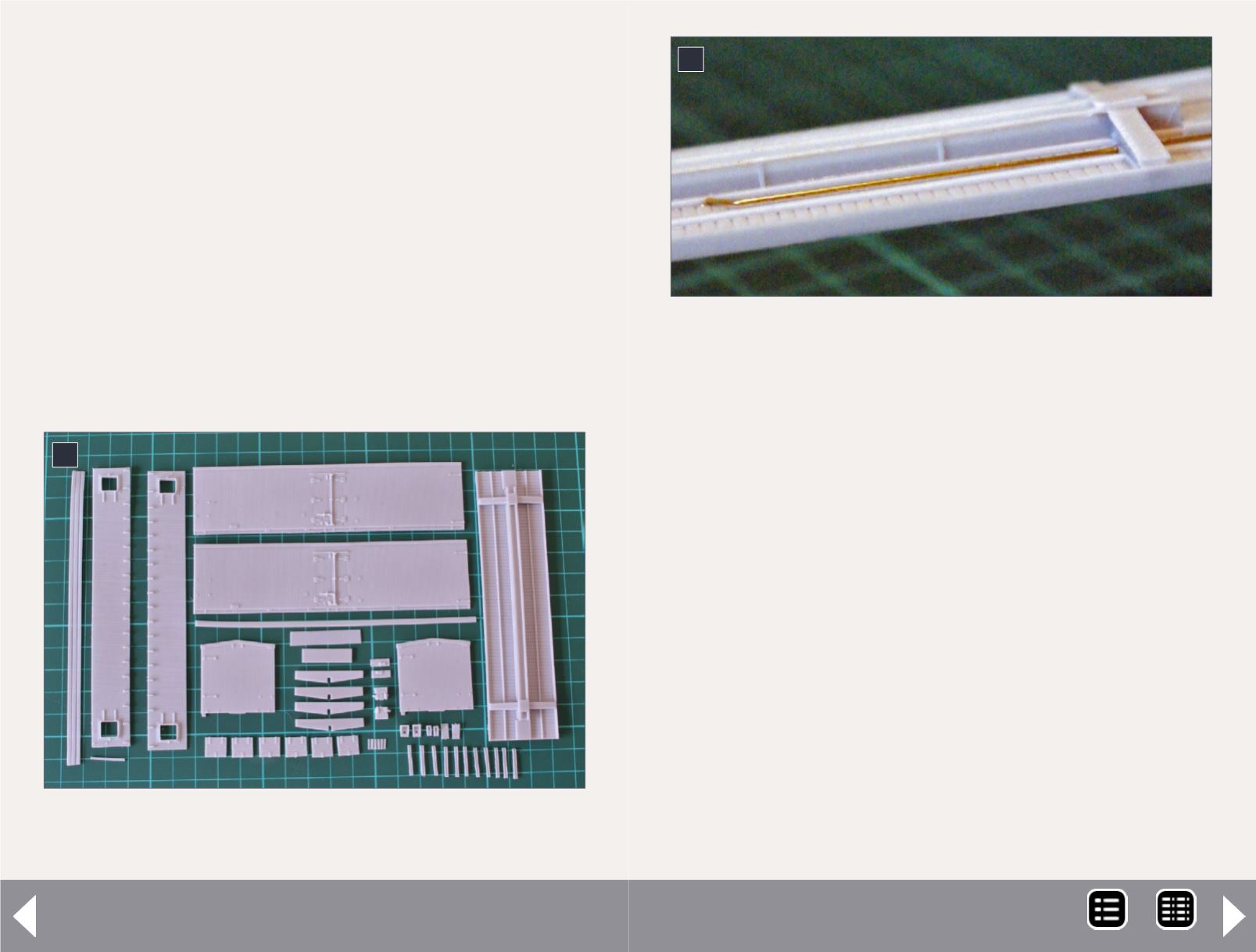

6. All of the resin parts with flash removed and ready

for assembly.

Build your first resin car - 4

6

The instructions call for painting the sides, ends, roof and

underframe before assembling the basic box. I find this hard

to do as it is practically impossible to clean up glue spills on a

painted surface.

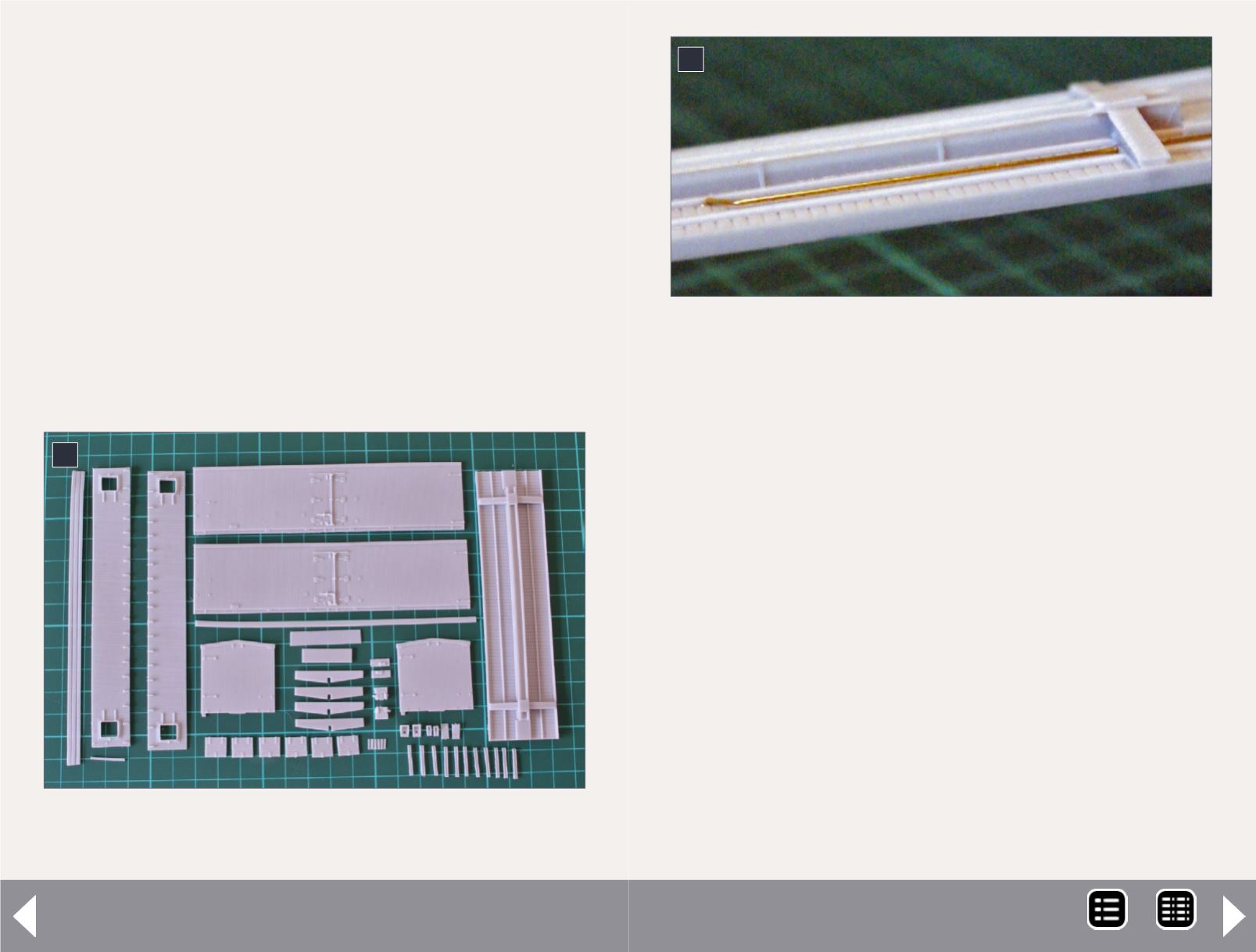

Begin with the underframe. This includes all of the brake parts

and stringers. Eight stringers are required. If you want to add

the train line for the brakes, do it now before installing the

stringers. The instructions on this kit did not call for a train line,

but I like to add it. I use .015” brass wire to represent the train

line and drill through both bolsters [7] with a size 74 drill for a

tight fit. TIP: Drill a small distance into the center of the car at

the angle so that the wire can be seated in the channel.

In [8] you can see a stringer ready to be attached to a verti-

cal rib. Before doing so, file a small indent into one end of the

stringer to help them to seat properly.

Now for the brake parts. I followed the instructions here and

added the brake reservoir, valve and brake cylinder with the

7. Train line attached to the underframe.

7

MRH-Aug 2014