Installing a sound decoder - 10

throw and the headlight will come on.) Advance the throttle a

notch or two and the engine should move forward. Stop and

change direction and the backup light should come on. If you

have a Firebox Flicker LED, press the function you wired it to

(5 or 6) and it should come on. Set its CV (51 or 52) to 141 and

the flickering should start. If the LED seems too bright, a dab

of yellow paint will soften the glare. If all these functions look

normal, you can assume you installed your decoder properly.

Now, take the engine back on the bench and put the headlight

bulb into the hole you drilled for it; I hold it in with some plastic

tape on the inside of the smoke box door. Then route the engine

wiring neatly so it is away from any moving parts and out of sight.

This is a good time to replace the boiler weight, but you may

have to saw off some of it to fit under the decoder. A hacksaw

with pretty large teeth works well, but be sure to file off any

sharp edges afterward. If possible, use the original mounting

holes and screw, but be very careful not to tighten it down and

pinch some wires. When you’re satisfied that the wiring is clear

and not pinched, put the boiler back on properly.

TIP:

It is easier to place the boiler upside down on a soft sur-

face and drop the frame/running gear down into it, rather than

fit the boiler down over the frame – you can see if any wires

are caught, pinched or in the wrong place. Then run the engine

on the layout for several minutes as a final test. Don’t forget to

set the decoder address to the number on the side of the cab.

I also like to set CV3 and CV4 to values around 30 or more, to

give easy more prototypical acceleration and slowing down;

this will also extend the life of gears and couplers.

Finally, I like to include a data sheet explaining the details of

the installation, a wiring diagram, and any CVs I changed from

the factory defaults. This will be handy if there’s a problem five

years from now when the details are forgotten.

I also encourage my customers to leave their engines on the

layout or in a larger box where they do not need to disconnect

the engine and tender each time they are used. This will wear

out the cable connectors pretty quickly and, unfortunately, the

cables do not come with a lifetime warranty. Replacing them

will be time-consuming and expensive.

I hope you enjoy your sound-equipped loco for a long time!

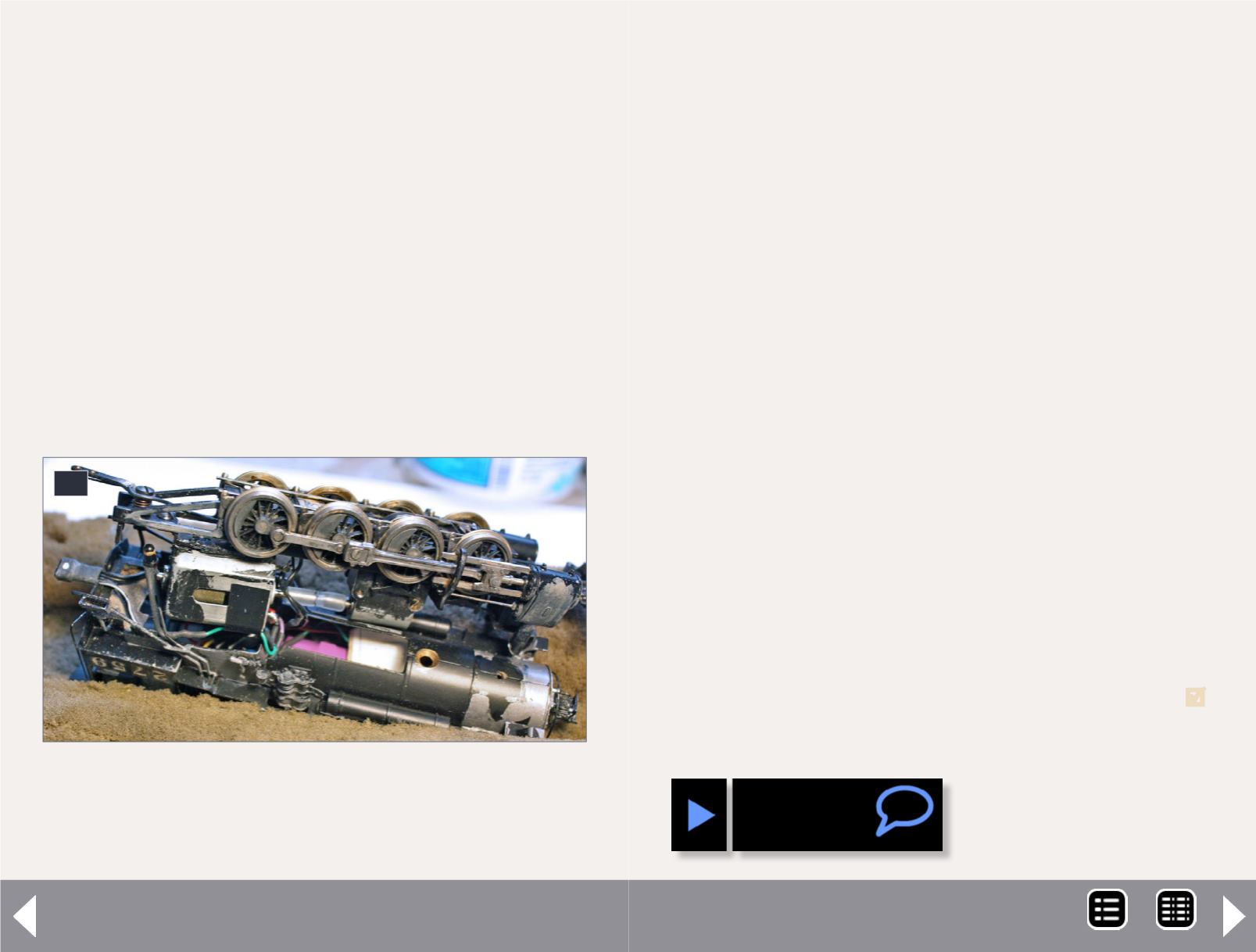

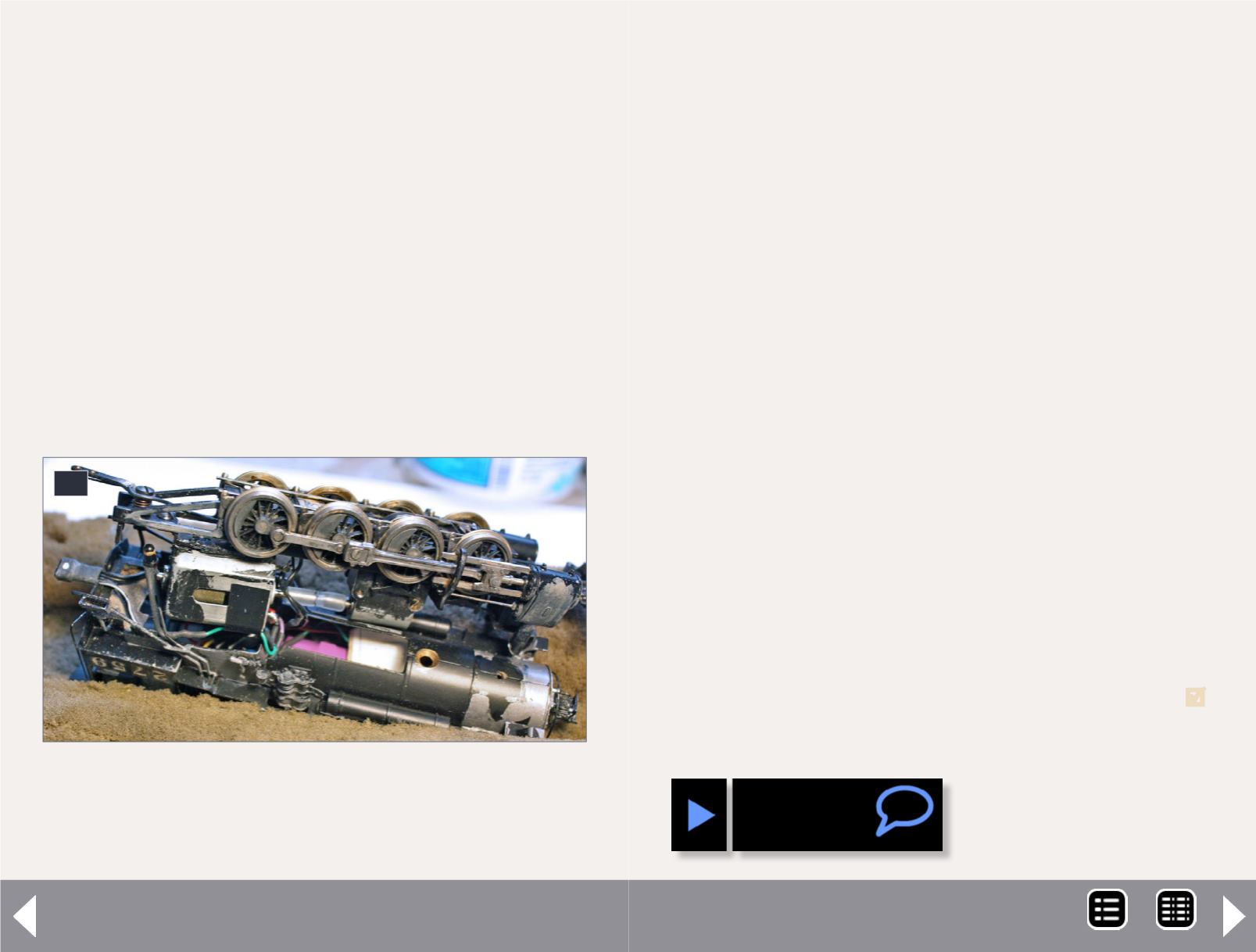

10: Drive is ready to drop into boiler – the Firebox

Flicker LED is to the left of motor, 4-pin cable in notch

in apron at left; pink decoder can be seen in boiler.

Wiring is carefully routed to avoid moving parts.

10

MRH-Dec 2013