Installing a sound decoder - 1

– By R. G. “Bob” Battles

Model Photos by the author

Installing a sound decoder

in an HO brass engine

Find out how to plan and install a

decoder in a brass engine ...

I

nstalling a sound decoder in a brass locomotive is not espe-

cially difficult for an experienced modeler, but it requires

some careful planning, familiarity with an ohmmeter, some

basic soldering skills and the ability to drill, cut and finish brass.

This article will assume you possess these skills plus the usual

modeler's hand tools, a decent ohmmeter and a soldering iron.

We will cover soldering small wires and components. The meth-

ods shown in this article are not the only way of doing them, but

they work and have been proven to be safe and reliable.

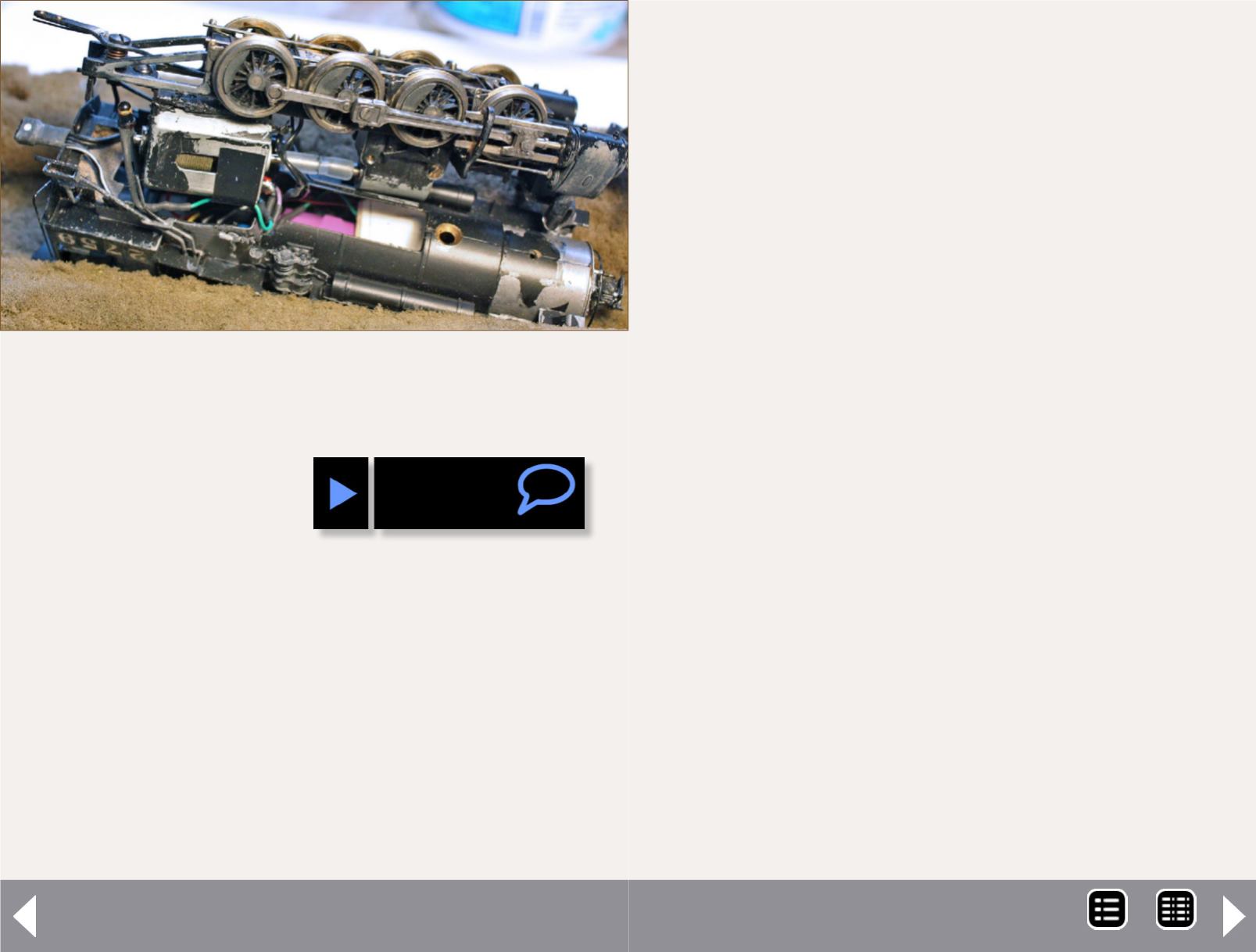

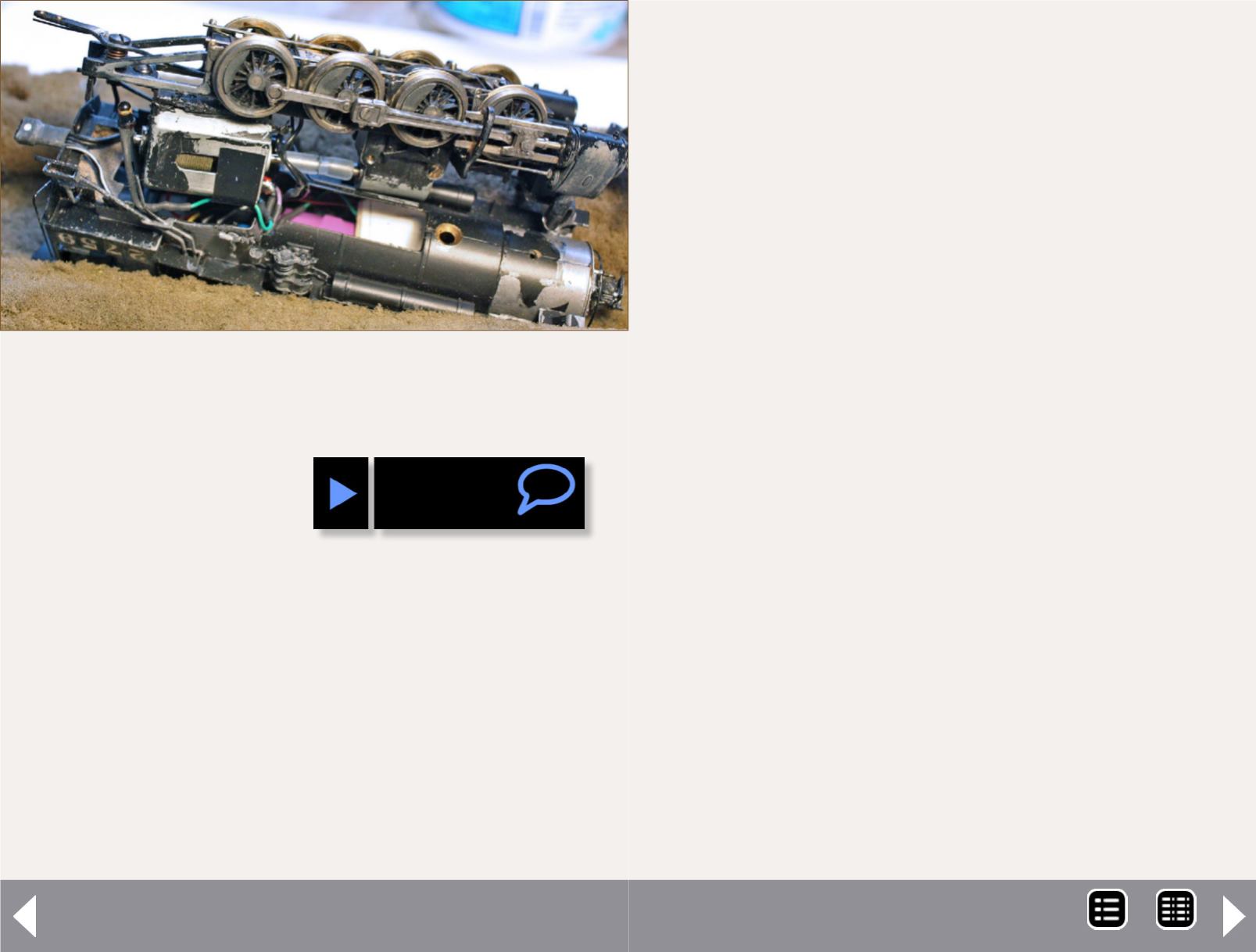

We will be installing a Soundtraxx Tsunami decoder in a

medium-sized engine, such as a 2-8-2, 4-6-2 or larger, but these

techniques and methods will work on almost any brass engine.

We will mount the speaker in the tender, and the decoder in

either the tender or the engine, depending on available space.

Obviously this will require a cable between the engine and ten-

der, and there are two or three that can be used, all reasonably

priced and readily available.

My philosophy has always been to mount the decoder inside

the boiler if possible, rather than in the tender. It makes add-

ing lighting functions, such as “Firebox Flicker,” Mars light, cab

lights, classification lights, etc., much easier and cuts down

on the number of wires running between the engine and ten-

der. Unfortunately, sometimes there just is not sufficient room

inside the boiler for the decoder, so this is a judgment call for

a given engine. I will point out a couple of items later that may

help you overcome space limitations.

Before we actually start the installation, we need to check

some basic items on your engine:

(A)

The engine you’re installing the decoder in should be

painted. I am very uncomfortable installing a decoder in an

unpainted engine, and here’s why: With the decoder installed,

the painter will disassemble the engine, putting a strain on the

wiring and disturbing electrical components.

Since the decoder and wiring cannot be completely removed

without unsoldering some wires, if any wires or components

become broken, damaged or torn loose during painting, there

is a good chance the decoder can be destroyed when powered-

up again.

If that happens, who has the responsibility to fix it and who

pays for it? In short, it can turn into a real hassle. With careful

MRH-Dec 2013