Installing a sound decoder - 4

cable that works very well. If this engine does not have a backup

light, you will only need a two-wire cable for the speaker.

The main criteria is this – there must be large enough open-

ings in the engine and tender so the cable is free to flex

without binding or limiting engine and tender movement on

curves and uneven track.

Since the engine is normally heavier than the tender, any

binds will usually show up on curves by the tender tilting

over, making poor contact with the track, derailing, or all

three. It is crucial that the hole in the tender front bulkhead

and the opening in the engine be the same height off the

rails; they must also be on the longitudinal centerline of the

engine and tender.

Take some time to measure and mark the locations accurately

so the holes line up vertically. Then remove the tender shell

and inspect it to be sure there is room inside to route the cable

past any bulkheads,

partitions or braces

and that there is room

on the frame/floor for

a speaker.

Any tender weights

may need to be

removed until this

portion is finished,

and reinstalled later

in a different spot. If

these items look good,

you can proceed with

making the cable

opening in the tender.

Figures 1 and 2 show

examples of the holes

cut for a four-pin

cable.

To make the opening,

I drill two or three

small 1/16” holes

first and then enlarge

them into one big

hole with a Dremel Moto-tool using a #113 engraving bit;

final shaping and smoothing is done with small files.

You must file the opening smooth with rounded edges so

they cannot snag or cut into the cable! I normally cut/drill the

four-pin Miniatronics cable opening at least 5/8” to ¾” wide

and about 1/4” high for the cable to feed through.

The TCS six-wire cable has much smaller wire so it is more flex-

ible and will not need as large an opening. With some engines,

there is plenty of open space under the cab, and running the

cable will be a simple matter, but others will require a hole in

the cab apron or even the frame. (While maybe easier, it looks

tacky for cables to be run on top of the cab and tender floor.)

Test-fit the cable with the engine and tender coupled, the cable

ends plugged together, and inserted into the holes you made. To

verify that the holes are large enough, you must be able to move

the tender up, down and sideways 1/2” independently of the

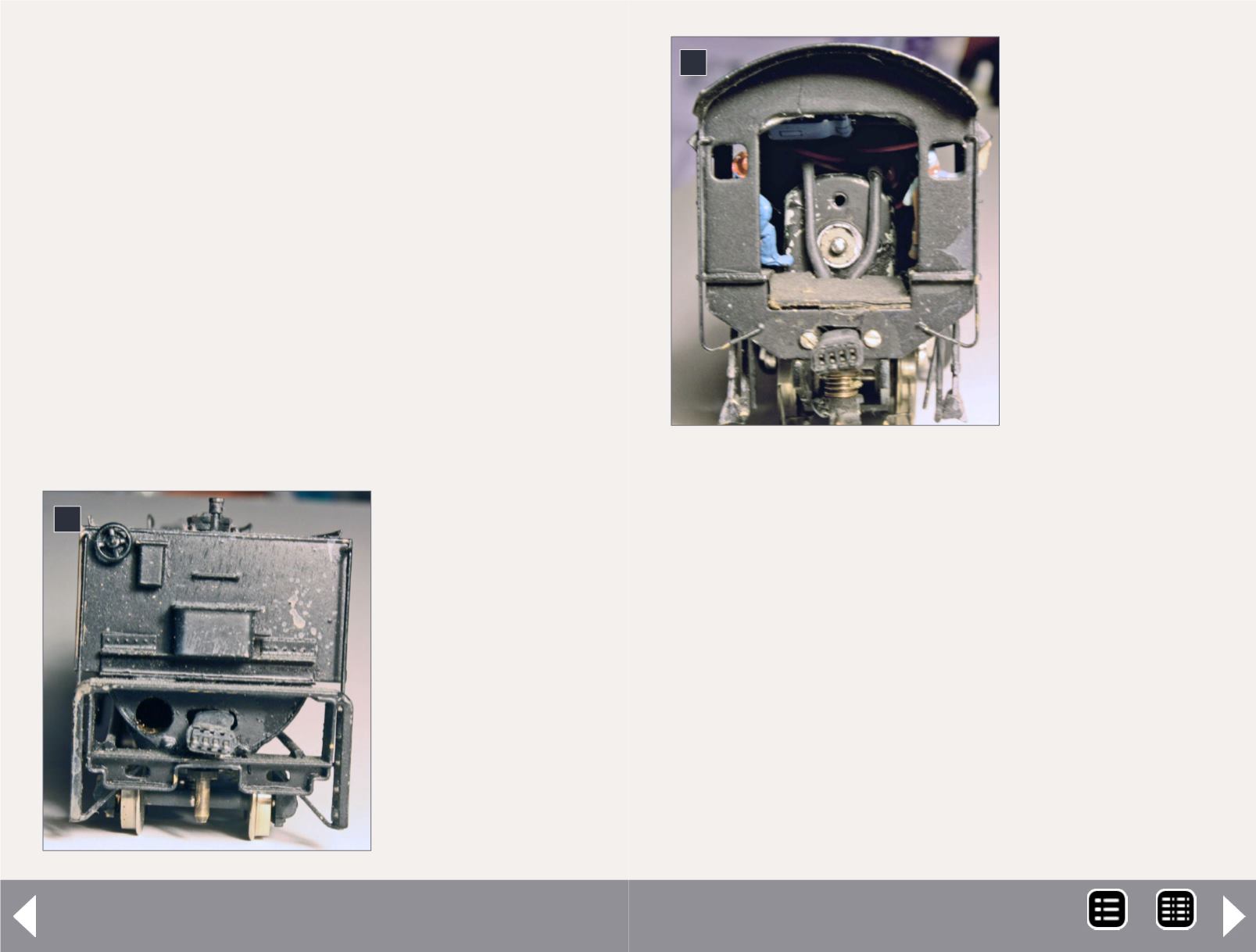

1: Front of tender

showing cable

cutout and cable.

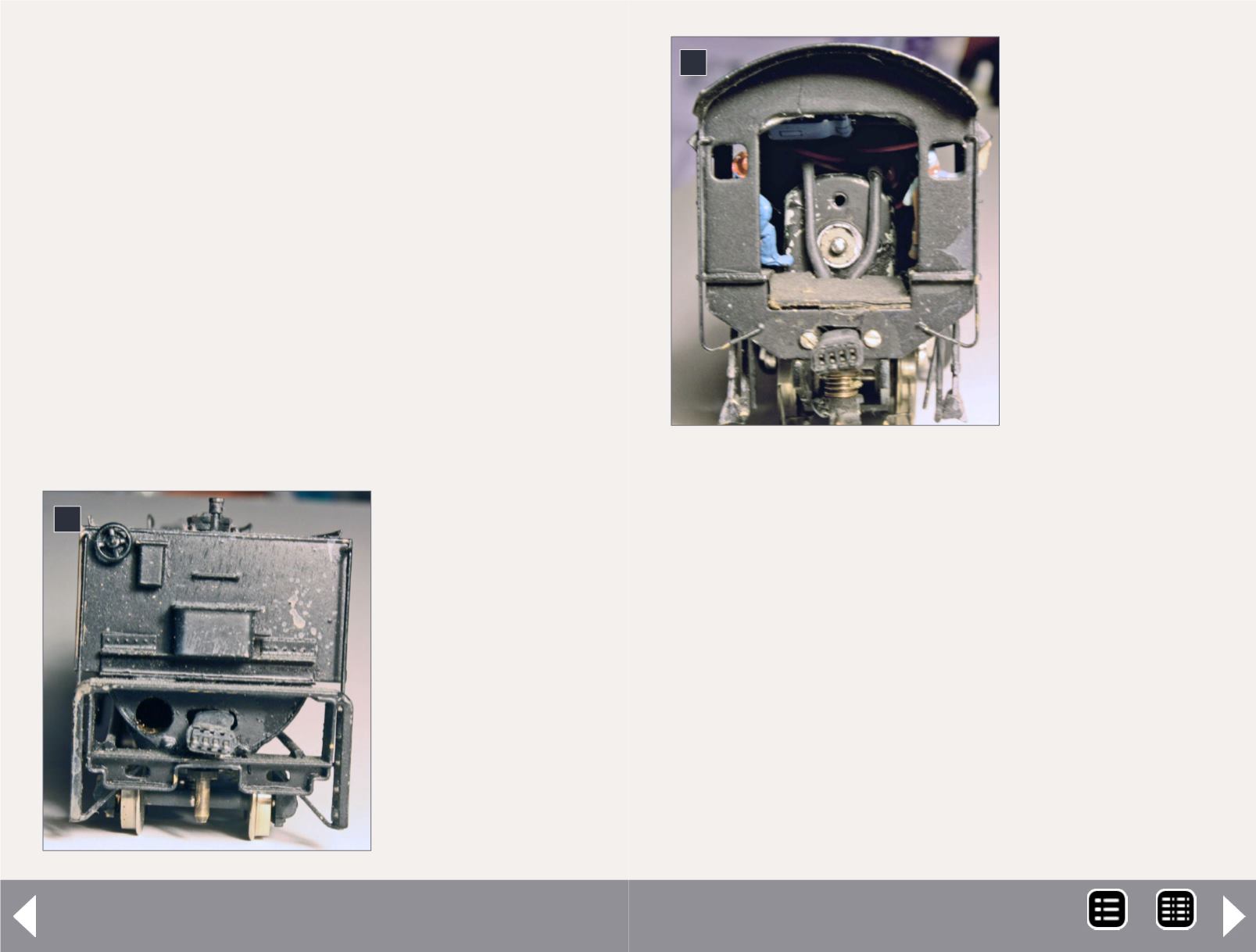

2: Cable cutout

in cab apron and

cable.

1

2

MRH-Dec 2013