Reserve the smooth edges for joints running across open scen-

ery, and hide the rougher edges along the backdrop, fascia. or

roadbed. When this is impossible, carefully cut the fabric paral-

lel to the threads and/or seal the edges with a little hot glue or

white glue to prevent fraying.

Applying the plaster

We use US Gypsum’s USG Hydrostone plaster [8], because that’s

what our local supplier carries. Other similar grades should do

just as well. Contrary to model railroad lore, there is only one

BURLAP HARDSHELL |

9

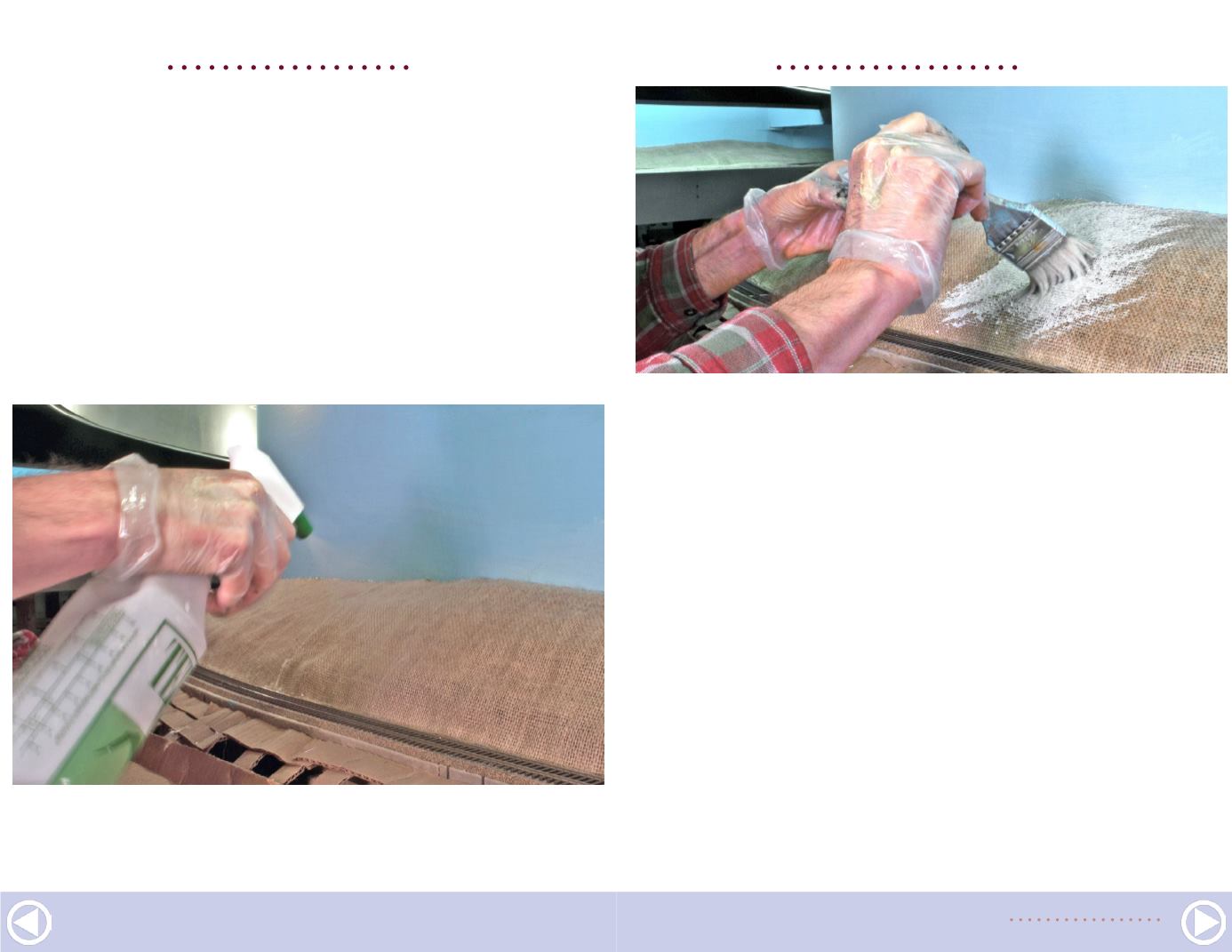

9. Spraying the burlap with wet water primes it to accept the

coat of creamy plaster and keeps it from drawing moisture out

of the plaster too quickly.

BURLAP HARDSHELL |

10

right way to mix plaster for optimum strength – which is accord-

ing to the manufacturer’s directions! That comes to 1 part water

to 3 parts plaster – by WEIGHT – for the plaster we use.

After making some density measurements, we found that a

mix of ¼ cup of plaster added to 3 tablespoons of water follows

the manufacturer’s recommendations fairly closely, and is a

lot quicker than measuring by weight. This size batch is small

enough that most modelers should have no trouble getting it

down before the plaster starts to set up. With practice, we have

found that a double-size batch is also practical but a triple-size

batch is too big to apply easily before the plaster gets too thick.

When mixed correctly, the fresh plaster will be no thicker than

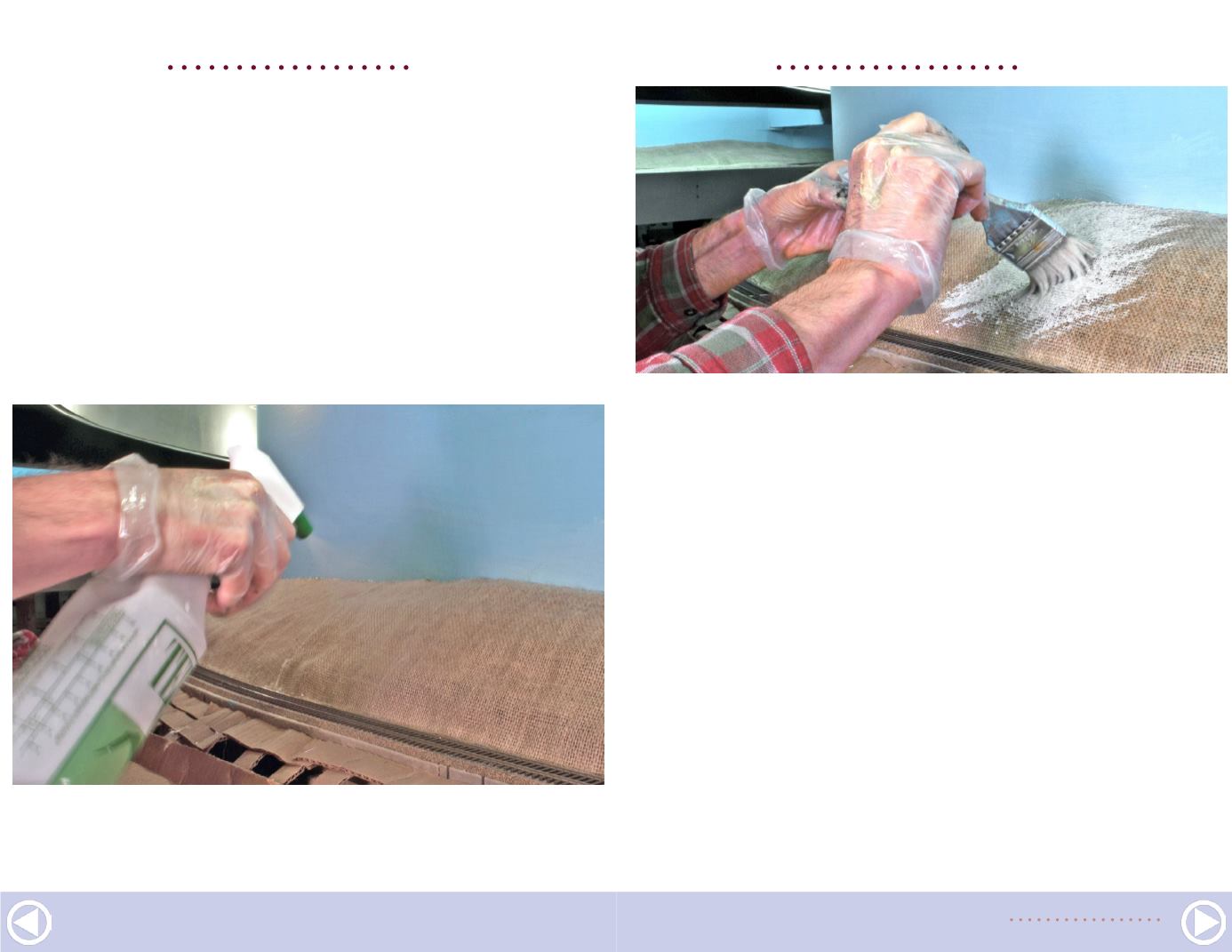

light cream. This is ideal for brush application. The best way to

apply the plaster is with a cheap 2” natural-bristle paint brush

available from places like Home Depot or Dollar Tree. Be sure to

10. Sideways brush strokes, at a 45 degree angle to the weave,

improve coverage and minimize plaster drips.