Although model railroad-

ers are accustomed to

using higher quality plas-

tic foam insulation for

scenery work, they should

not be tempted to use it

for tree support blocks.

The support wires, even

if sharpened, will create

large voids as they pen-

etrate that type of plastic

foam. The bead texture

material allows the sup-

port wires to penetrate

cleanly and anchor firmly.

Acknowledgments

The authors would like to thank fellow club members Steve

Cook and Dennis Markovich, who originally suggested and

discussed using burlap for scenery support.

See us at the PDX-Express

NMRA National Convention in

Portland, OR in 2015!

More about the Willamette Model Railroad Club

at

☑

BURLAP HARDSHELL |

13

beneath the site of each tree. A thin wooden support like a

barbecue skewer, cotton swab handle sharpened on one end,

or a long, round toothpick, is hot-glued to the back of each tree

trunk. The support extends down about 1½ inches below the

bottom of the tree trunk.

Modelers who want even stronger tree supports may want

to try pieces of coat hanger wire or, for ultimate strength,

sharpen the ends of pieces of the heavy wire from excavation

marker flags available from the Home Depot plumbing supply

department.

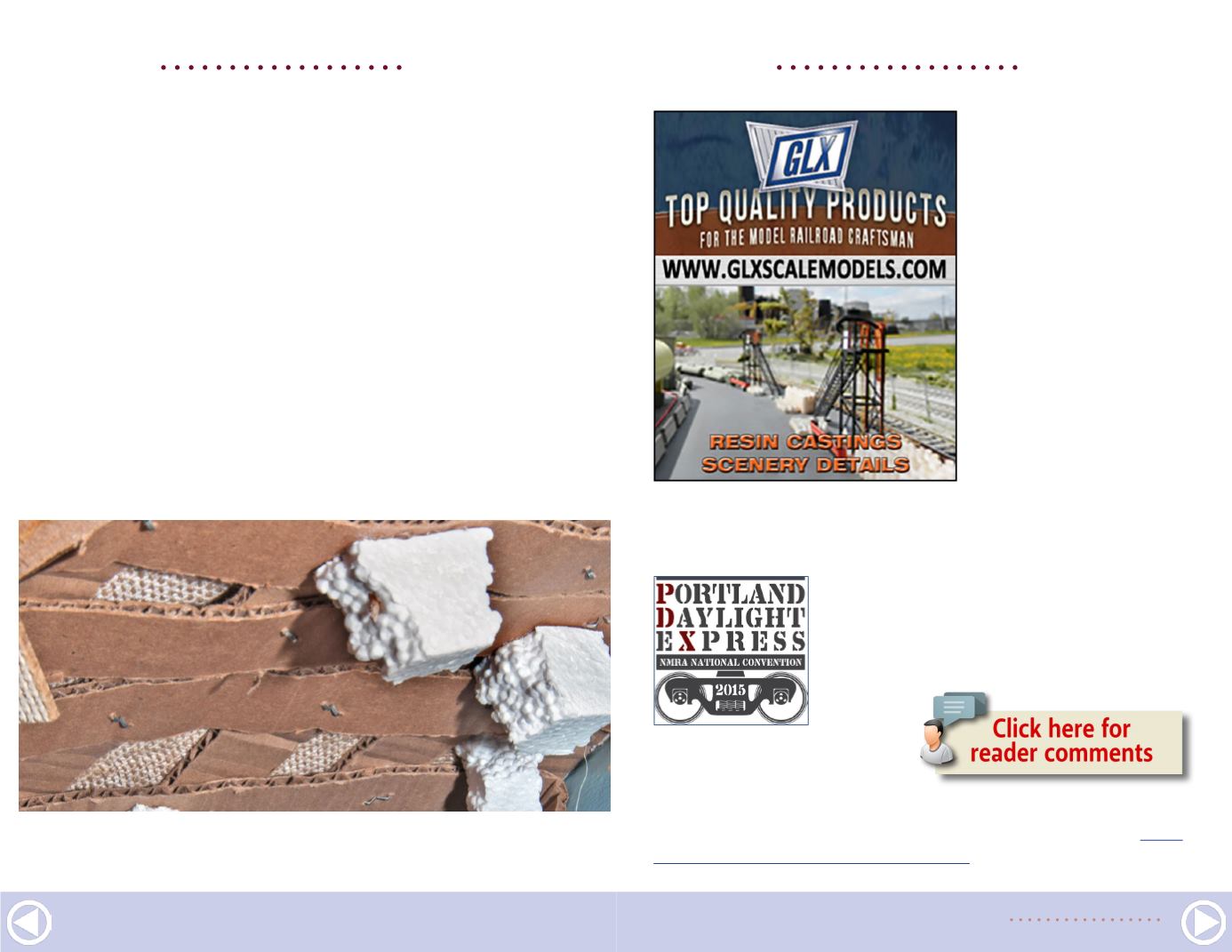

Planting trees becomes a three-step procedure: A foam block is

glued to the underside of the scenery below the site of the tree,

a small hole to accept the tree support is drilled or punched

through the plaster layer above the foam block, and the tree sup-

port is placed through the hole and into the foam block below.

15. Beaded foam plastic blocks hot-glued to the underside of

the hardshell will hold the trees in place.

BURLAP HARDSHELL |

14

ADVERT I SEMENT