to the motor, similar to a DCC

decoder’s speed control.

If left idle for many days the

battery will drain down. The

battery manager board will

isolate the battery from fur-

ther discharge to protect it.

The DC-DC converter needs

to be isolated from its load to

reset its operation. So a mag-

netic reed switch is used to

remove the load when not in

use, and limit battery drain.

Headlights

Working headlights are built by gluing sunny-white 0603 LEDs

onto the back of an MV Lens, with a 1/16” shallow hole barely

drilled into its center rear [24]. I use the pre-wired LEDs avail-

able from LedBaron

quite

a bit. For older models, I

like the effect it gives, with

a white LED with a yellow-

ish tint. I used to simply

glue the LED in the back of

the headlight housing, and

cover the front with a clear

styrene disk punched out

with a paper hole punch.

But I think the MV Lens

combination is an improve-

ment. Add some clear glue

26. 0603 White LED & MV

lens with rear hole.

26

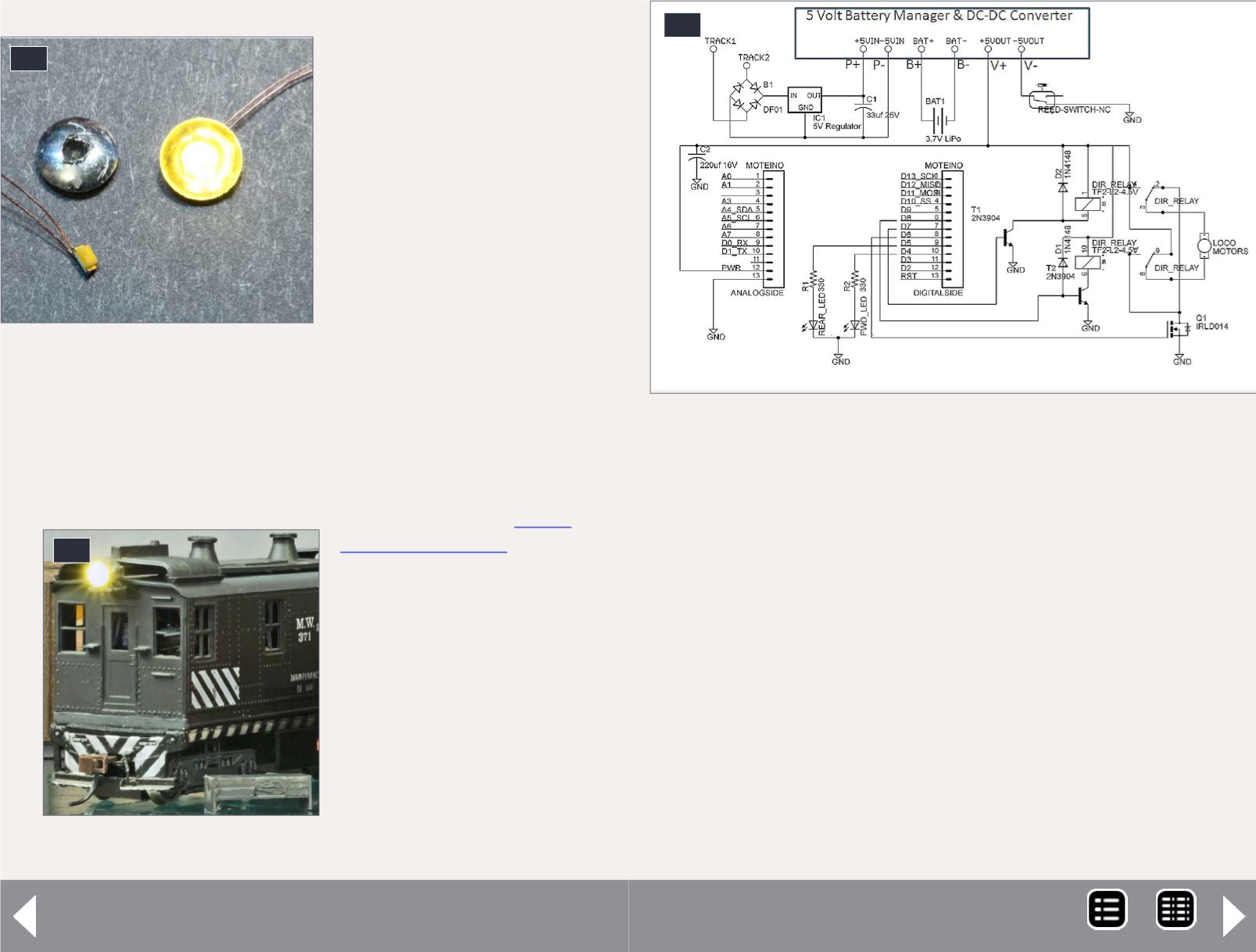

27. Loco with “magnet box.”

27

Battery-powered models - 11

to cover where the wires attach to the LED back too, to insulate

the wire contacts and strengthen the connections.

All components are mounted on a piece of perf board run-

ning the length of the body shell and screwed to the top of the

chassis. The reed switch is mounted at the highest point, in

the middle and just under the roof. I use a small magnet glued

into a box-like structure, painted the same color as the body, to

make an unobtrusive on/off switch [25]. These reed switches

have worked out so well that I have ordered more to use in

future models.

Remote control

A model loco providing its own power will no longer respond

to voltage changes on the rails (DC) or to power and signal on

the rails (DCC). In fact, battery operation is by definition (at

28. Locomotive battery power block diagram.

28

MRH-Nov 2014