the body. The motor trucks are disassembled. Cracked axles

should be replaced or repaired. Solder two thin, very flexible

wires to the side frame contacts directly (I replaced the ones

that came with the unit), and carefully solder two more directly

to the motor brush supports. Don’t melt the housing or you

may destroy the motor. This gives us independent pickups and

isolated motor contacts for independent control. I covered the

leveled top of the metal chassis with Kapton tape to prevent

any possible electrical shorts.

The block diagram outlines the power and control scheme.

In the first model, everything is powered with 5 volts from

the basic power block, exactly the same as the caboose light-

ing application. Even if you’re used to working with electron-

ics, battery power adds more constraints to design. I started

using the same H-Bridge devices I had used before (like the

SN754410 driver and the L298 device). But with only 5 volts

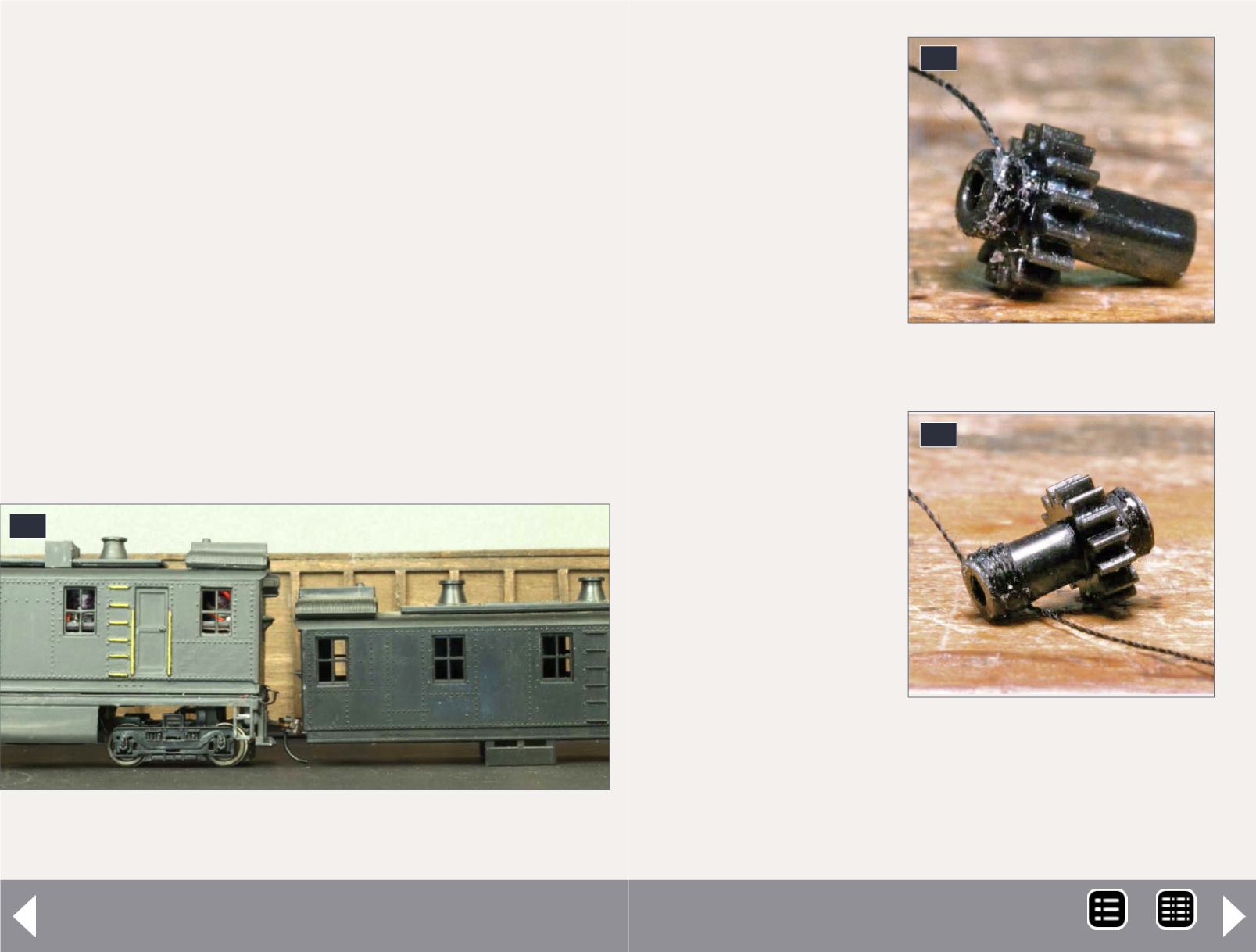

19. Original boxcab shell on right before bottom tabs

are removed.

19

Battery-powered models - 9

available they did not

provide enough voltage

swing out to the nomi-

nally 12-volt motors.

As an aside, I did con-

sider re-motoring with

6-volt motors but found

success before I had

to resort to this. I am

now considering using

a 6-volt or even a 3-volt

motor in the original

Roundhouse Boxcab

mechanism, even with

its poor power trans-

mission. The H-Bridge

designs usually solve

the problem of using a

single voltage source to

power a DC motor both

forward and reverse. I

even tried using a dis-

crete FET H-Bridge with

poor results. Success

came via a throwback! I

used an electromechan-

ical relay as a double-pole double-throw switch, just like DC

power packs typically use. The problem was the typical relay

would constantly draw power in its activated state, decreas-

ing battery life.

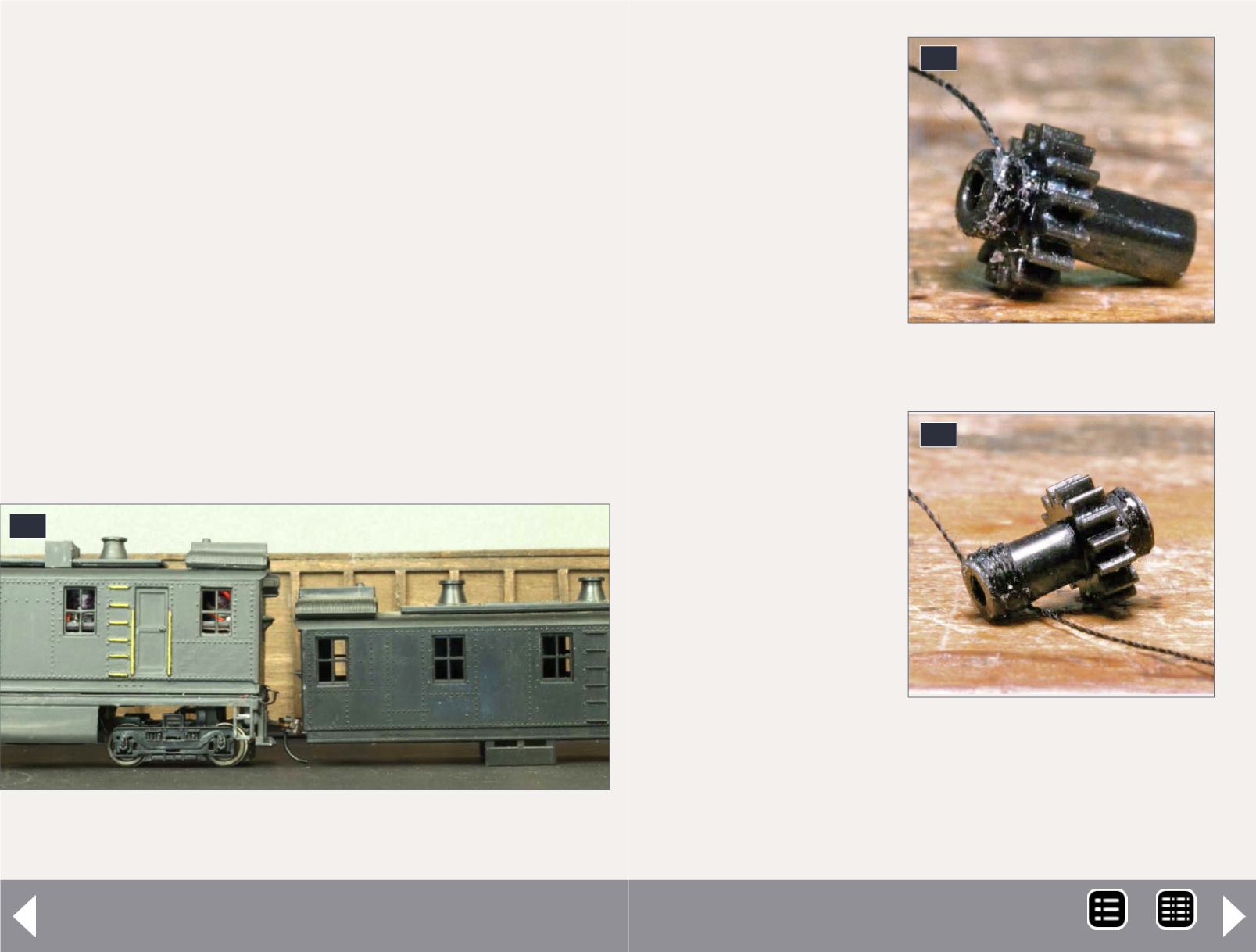

20. Repairing gears.

20

21

21. Wrapping the axle.

MRH-Nov 2014