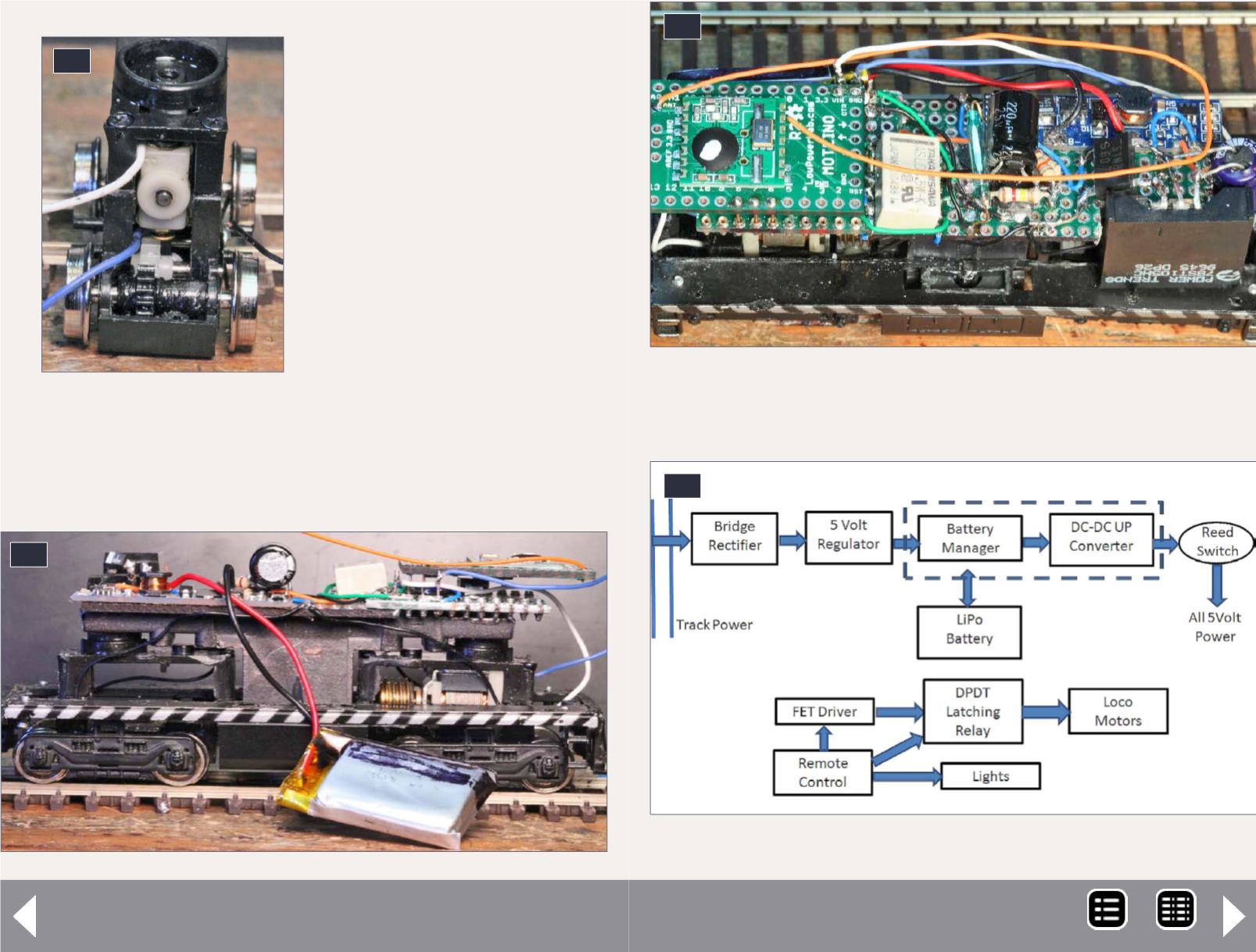

The solution was to use a tiny

latching relay which only needed

a short pulse to switch the con-

tacts. Look for 4.5-volt dual coil

latching relays at Digikey.com

or Mouser.com. The relay holds

its position until pulsed to the

opposite position. To maximize

the voltage swing to the motor,

a single, logic level FET transistor

was used to pulse (Pulse Width

Modulation - PWM) the power

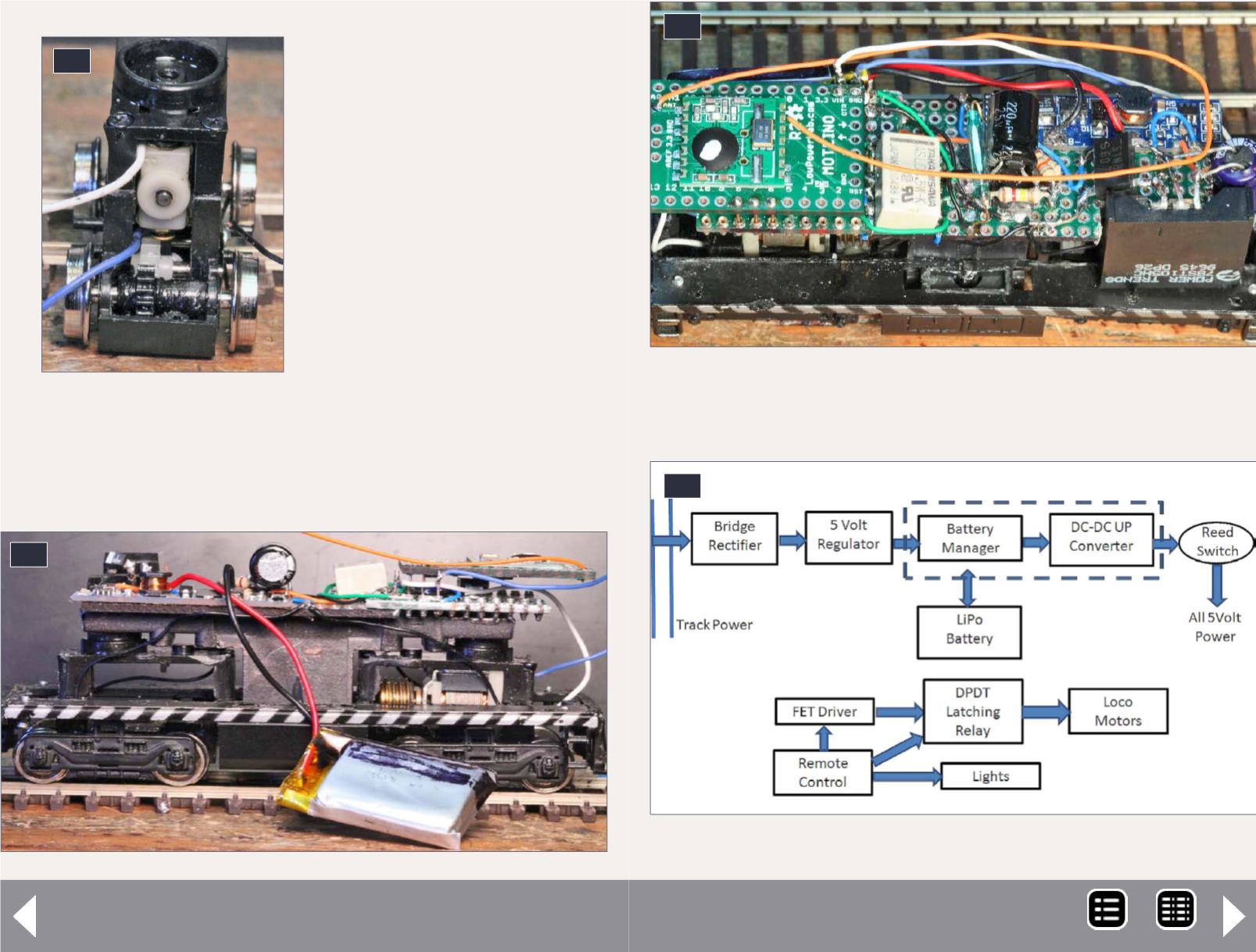

22. Repaired gears back in the power truck. Note the

new motor wiring.

23. Loco1 boards mounted atop the 44-ton chassis. Note

that the left power truck has had its motor removed.

20

23

Battery-powered models - 10

24

24. Loco1 with 78ST105HC regulator mounted.

25

25. Locomotive battery power block diagram.

MRH-Nov 2014