brass wire pieces in the handrail kit or bend your own from

one long piece of wire. I use the second option for my mod-

els but this does take some practice. You also have to decide

if you want to solder the handrails to the stanchions or glue

them. Soldering definitely makes the strongest handrail, but

you have to be careful not to melt any parts on the plastic

shell. I suggest the use of flux, heatsinks, and perhaps a low-

temperature solder. On my recent models I have used Mi-

croscale MicroBond to glue the handrails to the stanchions, in

fact I now use MicroBond in all situations where I used to use

regular CA adhesive.

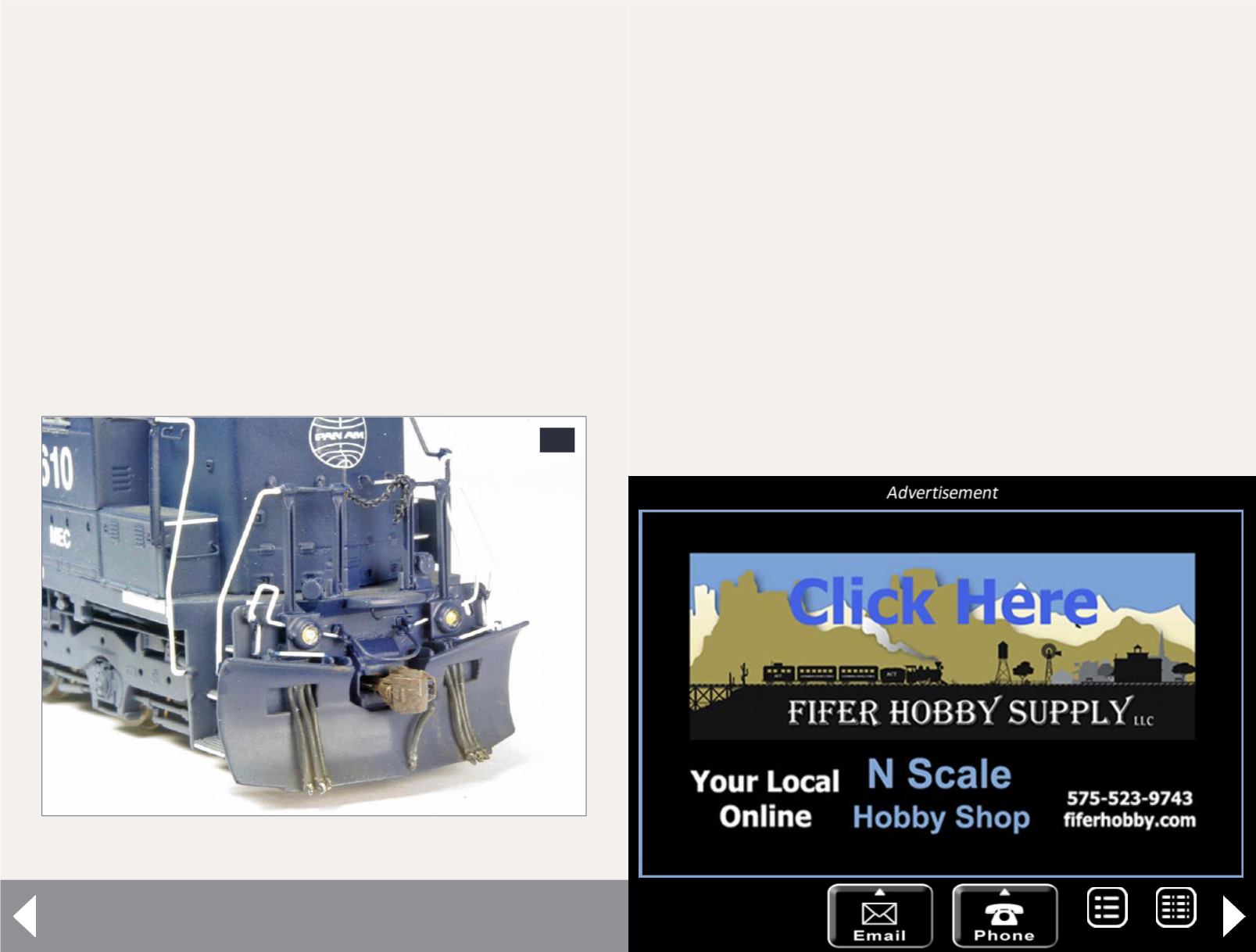

Continue with all the other handrails, following the Smokey

Valley instructions and photos. When drilling the vertical

35

35. View of finished front pilot.

Pan-Am Railways SD45R - 17

holes for the end stanchions, be careful not to drill all the way

through the anticlimber.

Once most of the work is done to the shell, you can add the

fragile parts which could be easily damaged or broken off. On

this model that includes the details on the cab roof, the sun-

shades above the cab windows, and the underframe bell.

Install a Details West 373 horn rather than the horn included

in the Details West SD45 detail kit. Drill a hole in the top of

the number board assembly for mounting the horn. Trim the

mounting pin on the horn so it is long enough to provide a

strong mount but short enough so it will not interfere later

when you are installing headlights. I used two spacers made

from styrene strip while gluing the horn so it would be at the cor-

rect height. The front spacer is a piece of .030”x.060” strip and the

rear is a piece of .030”x.080” strip. These can be seen in [34].

MRH-Oct 2014