The final clear coat of Testor’s Dullcote, thinned 50/50 with

lacquer thinner, was applied after the weathering had dried. As

usually happens, most of the chalk dust I’d applied to the roofs

[23], disappeared. If I get inspired, I may go back later and add

more dust as appropriate.

Following the Dullcote, I added the .010” clear styrene window

glazing. Adding it before the Dullcote would have either meant

I’d have to mask all the windows or live with the frosting that

occurs with Dullcote on clear windows. I did the caboose #2

clerestory windows using a scrap of blue-tinted clear styrene

from my scrap pile. Now and then it pays to stash away some

of those arcane but useful-looking pieces of hardware at the

end of a project.

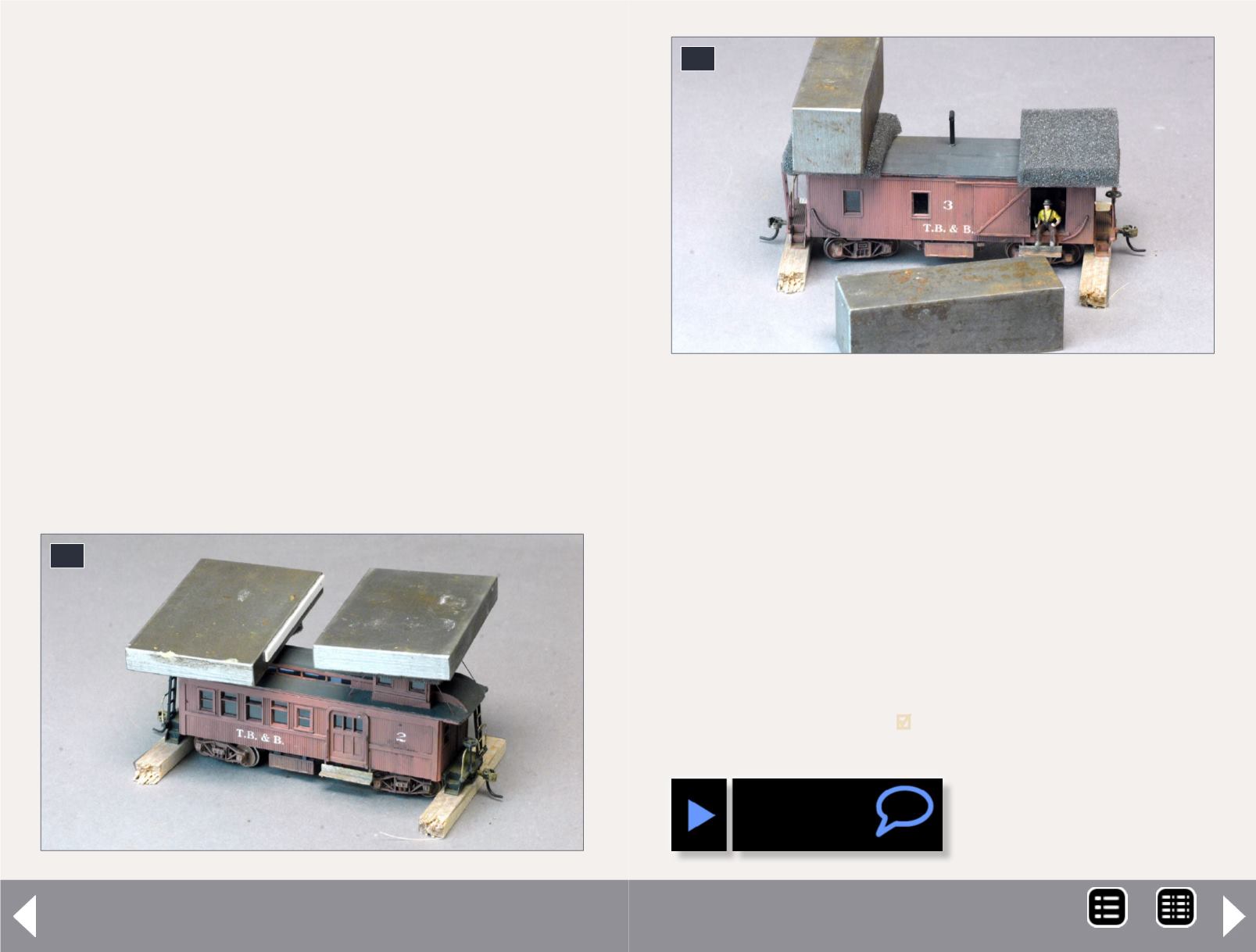

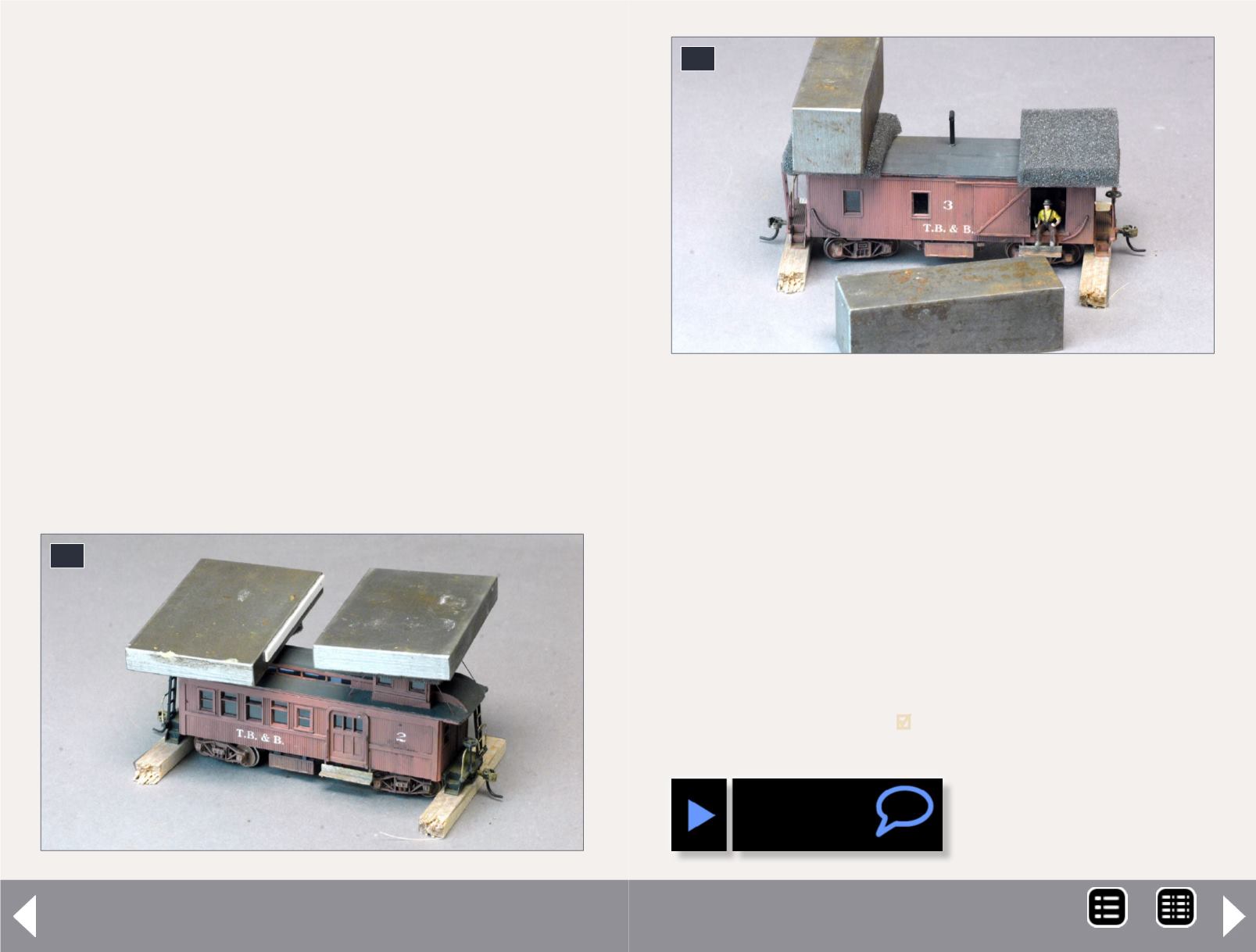

I have no plans for further interior detailing or lighting, so I

glued the roofs in place. I applied small dabs of Walthers Goo

to the roof lip that fits inside the body, positioned the roofs,

and held them in place with weights, as shown in [24 and 25].

Logging cabooses - 11

22

The balsa scraps under the end steps help hold the body stable

while the weights are in place.

The end result of this project is a pair of unique cabooses for

our layout’s logging trains. They’re fun, they look plausible

based on logger ingenuity and prototype photo inspirations,

and they were inexpensive and easy to kitbash using readily-

available materials. I highly recommend the effort if logging is

part of your railroad plan

.

22-23. Metal model assembly weights with small foam

pads were used to hold the roofs in place until the

adhesive dried. The wood scraps under the steps help

keep the bodies steady while the weights are in place.

23

MRH-Oct 2014