box. There’s also the foam-on-a-slab-of-MDF approach. Both

of these are perfectly valid ways to build modules, but liv-

ing within the spirit of our $500 budget – and the mindset

that these are miniature platforms for experimentation that

we might not want to get too attached to – I’m proposing an

even simpler technique: foam-core. True, it’s not as rigid as ¾”

furniture-grade plywood many use for room-filling layouts, but

for the size of these modules, it’s actually sturdy enough. And

the assembly cost can’t be beat: a dollar-store box-cutter and

a two-dollar sheet of foam core can get you a basic module in

about half an hour. (I don’t, however, recommend dollar-store

foam-board for construction, as that is too flimsy.)

That’s a lot of experimentation potential, using only a small

fraction of our $500 budget. And truth be told, after you’ve

built the first few modules using foam-core, there’s still the

option to try the other construction techniques. Later.

A single 16” x 20” sheet will yield a single standard-size mod-

ule, with leftovers. I bought a name-brand three-sheet package

$500 layout 3rd place - 3

T-Trak

T-Trak has taken off over the years, but the one go-to place

is still

t-trak.org,

run by Lee Monaco-FitzGerald, founder and

staunch advocate of all things T-Trak. Paul E. Musselman also

has a rather extensive “unofficial” T-Trak site, with many great

ideas. And I’ve written a word or two on the subject as well. I

recommend you visit each to get some ideas, and to more fully

appreciate exactly what you can fit into such a small size.

The home of T-Trak:

The “unofficial” T-Trak site:

A word or two from yours truly:

.

for just under $6 from one of those big-box retailers, so count-

ing the few drops of glue you’ll use, figure a basic module will

run you around $2.00 [1].

To put one of these modules together, get out a single sheet

of foam-core, and grab some Unitrack that is 310 mm long.

(Unitrack track comes in multiples of 62 mm, so a single piece

of 186mm track from Kato 20-000 and another 126mm piece

from a 20-040 snapped together make the needed length.)

This track becomes your gold standard measure, since you’ll

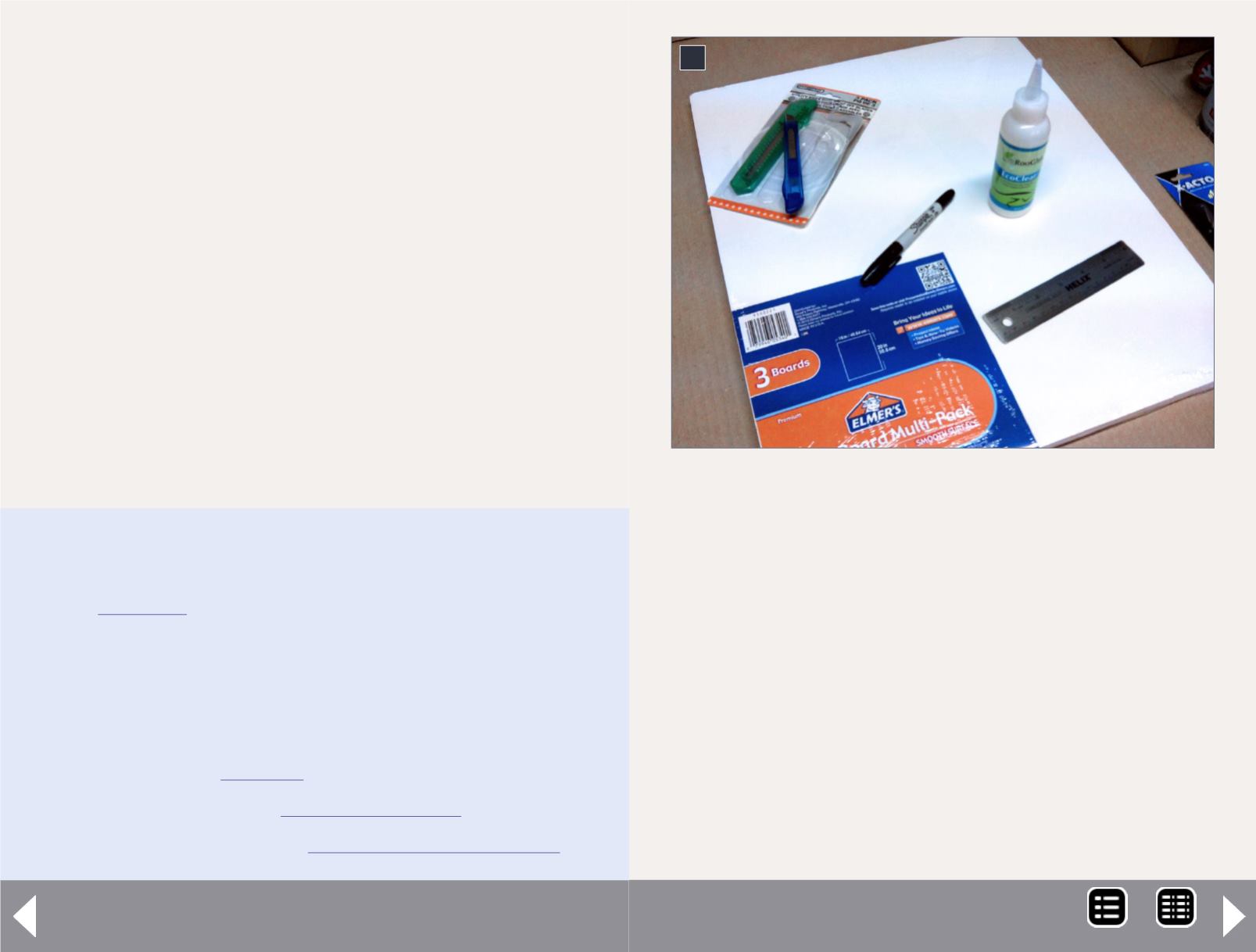

1. Shown are the basic materials necessary: some

foam board and glue. A pen helps you mark where you

will cut, a simple retracting knife does the cutting, and

a straight-edge keeps the cut nice and straight.

1

MRH-Oct 2014