Roof filler

Next I filled in the roof opening, once occupied with a cupola,

using two chunks of .020” Evergreen styrene [17]. This could

have been done with scribed styrene because the scribing may

have come through the tar paper roof material and resem-

bled the wood used by the shop crew to patch the hole, but I

thought of that after the smooth material was in place.

It’s easy to line up the patches with the roof surface by assem-

bling the parts top-down on a work surface. At that point

it’s convenient to add the scrap styrene underside bracing to

ensure the patches stay in place.

Logging cabooses - 9

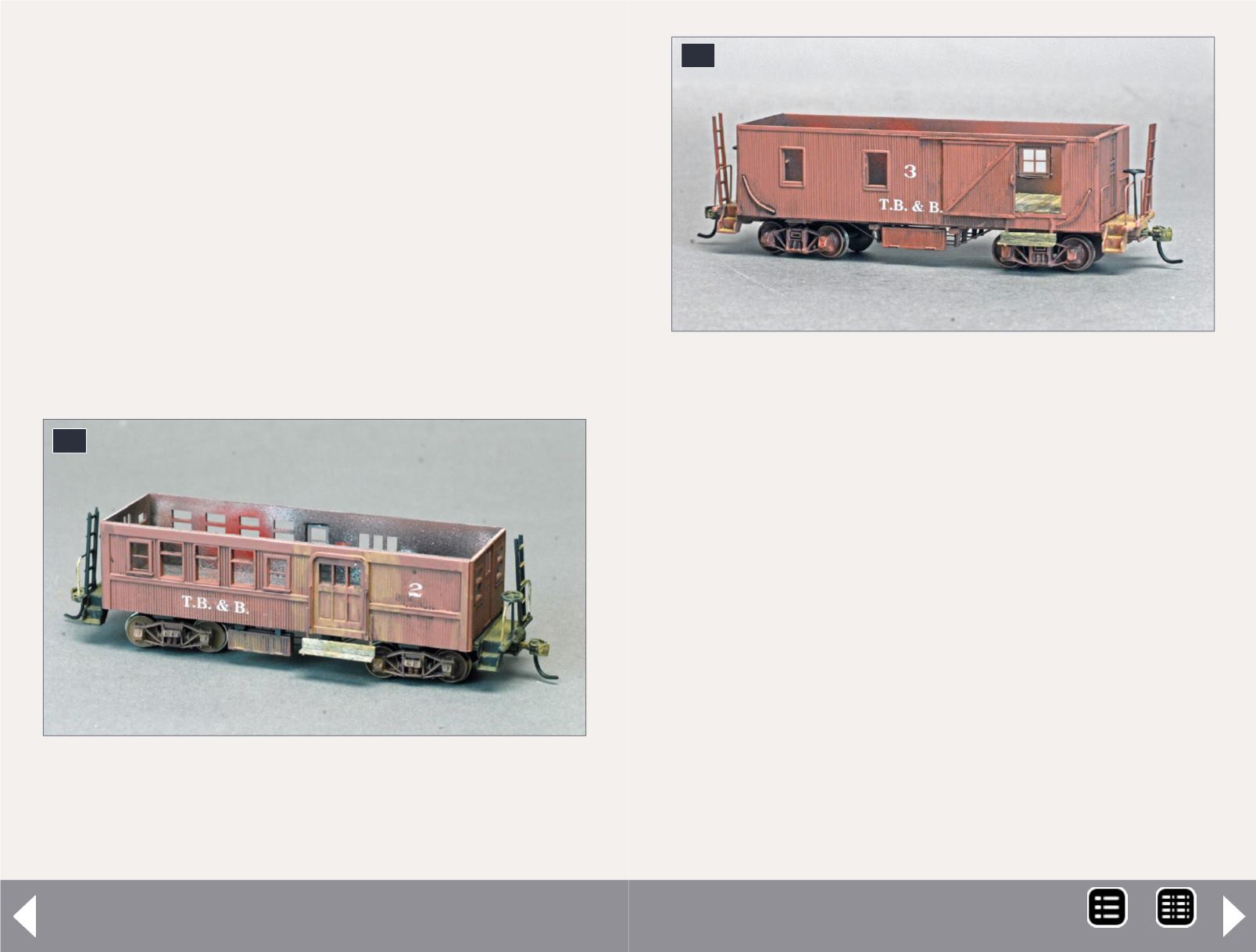

18

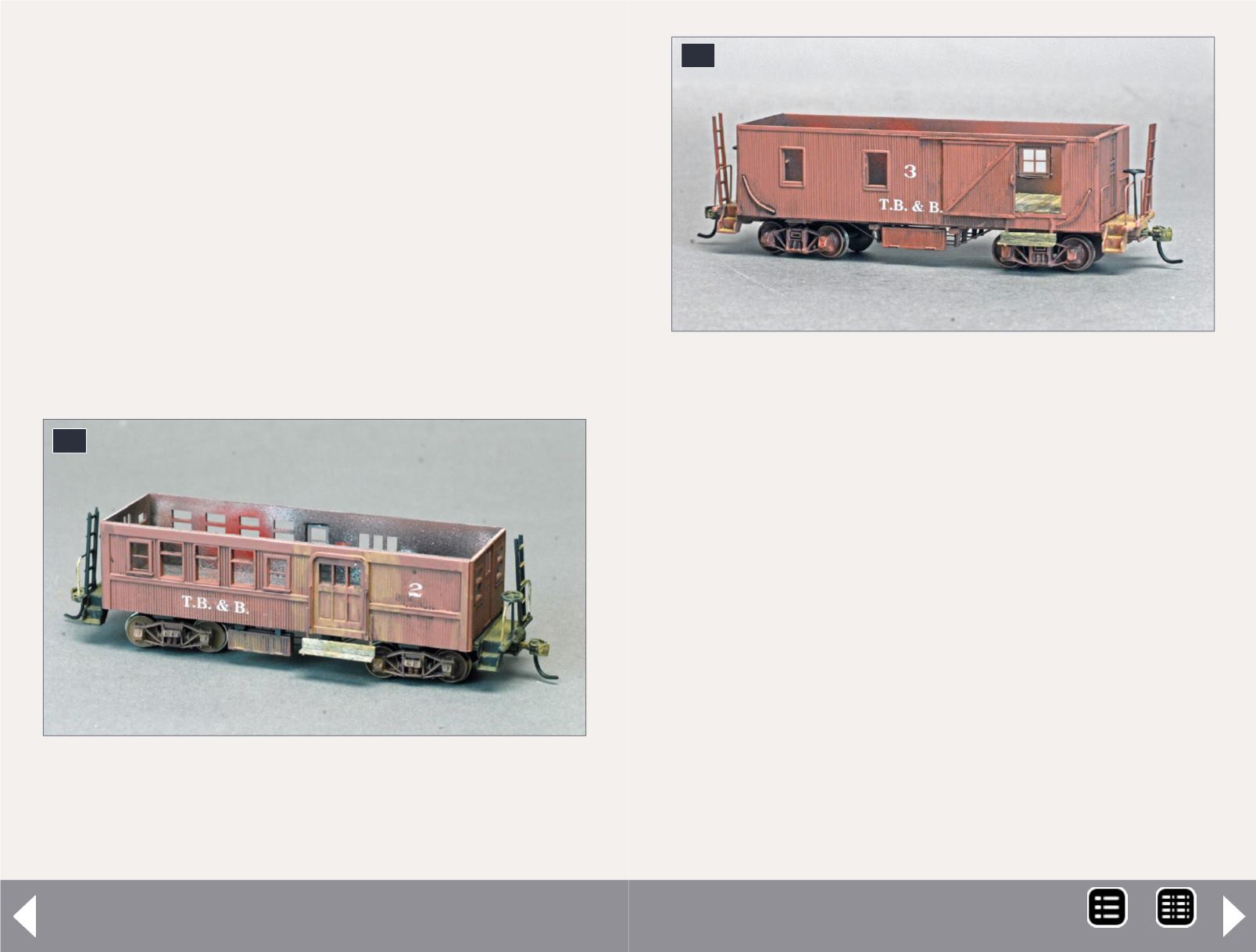

18. The original weathering wash for #2 was too heavy

so it was covered with a wash of the Boxcar Red body

paint to tone it down. The rest of the caboose is about

ready for the flat finish.

Paint and finish

As mentioned earlier I painted the caboose body, underframe

and trucks with PollyScale Boxcar Red #414281. The roof

needed only its underside at the end overhangs and outer

edges done, as the top was covered with the tar paper. The

roof was done using the same techniques described earlier for

caboose #2. Also, the access step was built just like the similar

piece on caboose #2, discussed earlier.

Because of the view through the side door, I added a wood

floor to the cargo area [18]. It’s made from 1x12 scale strip-

wood stained with the mix of India ink and alcohol and secured

with medium-viscosity ACC. I didn’t mess with decorating the

walls, but added a few small detail items [19] inside to provide

a more interesting view when looking in past the seated figure

in the doorway. The metal plate at left in the photo is a piece

19

19. The left side of #3 is ready for the flat finish. The

window glazing was added after the Dullcote to avoid

hazing the windows with the finish.

MRH-Oct 2014