At about the same time, Greenville Steel Car Company devel-

oped a proprietary end that was similar to the Despatch end.

The design was used exclusively on cars built by Greenville.

Railroad historian, Richard Hendrickson, cites the ends on the

B&O M55c class boxcars Greenville built in 1945 as an example

of this practice [43].

In the 1970s, Stanray introduced heavy non-terminating

box ribs that were welded directly to the corner posts [48].

The non-tapered design provided some flexibility in the

42

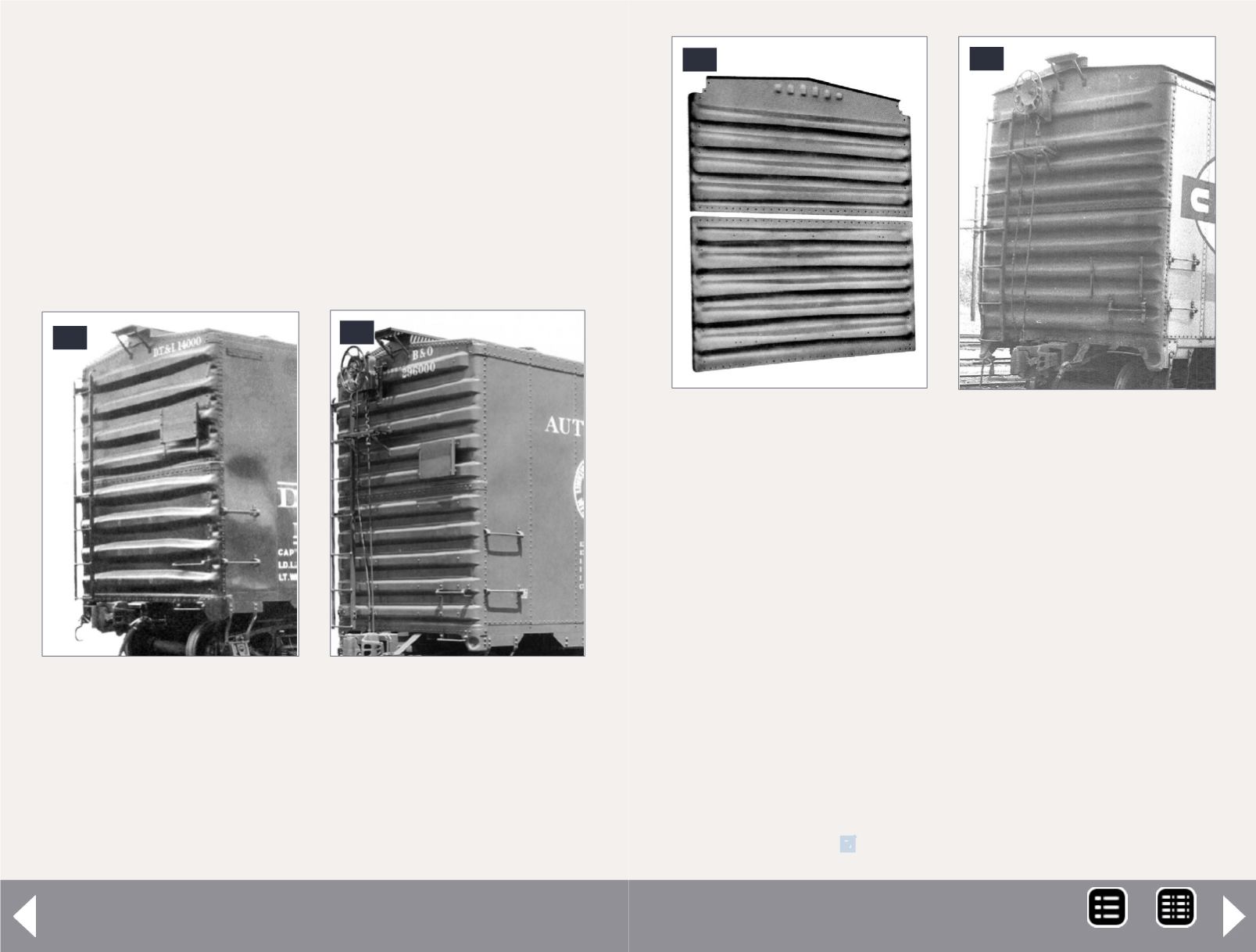

43 Greenville Steel Car

Co. built this car in 1945

with a 5/5 end with non-

tapered ribs that wrap

around the W-section

corner post. Note the

shortened top rib.

43

42. Corner dimples

between the dart-free

ribs identify this as an

ACF proprietary end

introduced in 1948.

Boxcar ends - 13

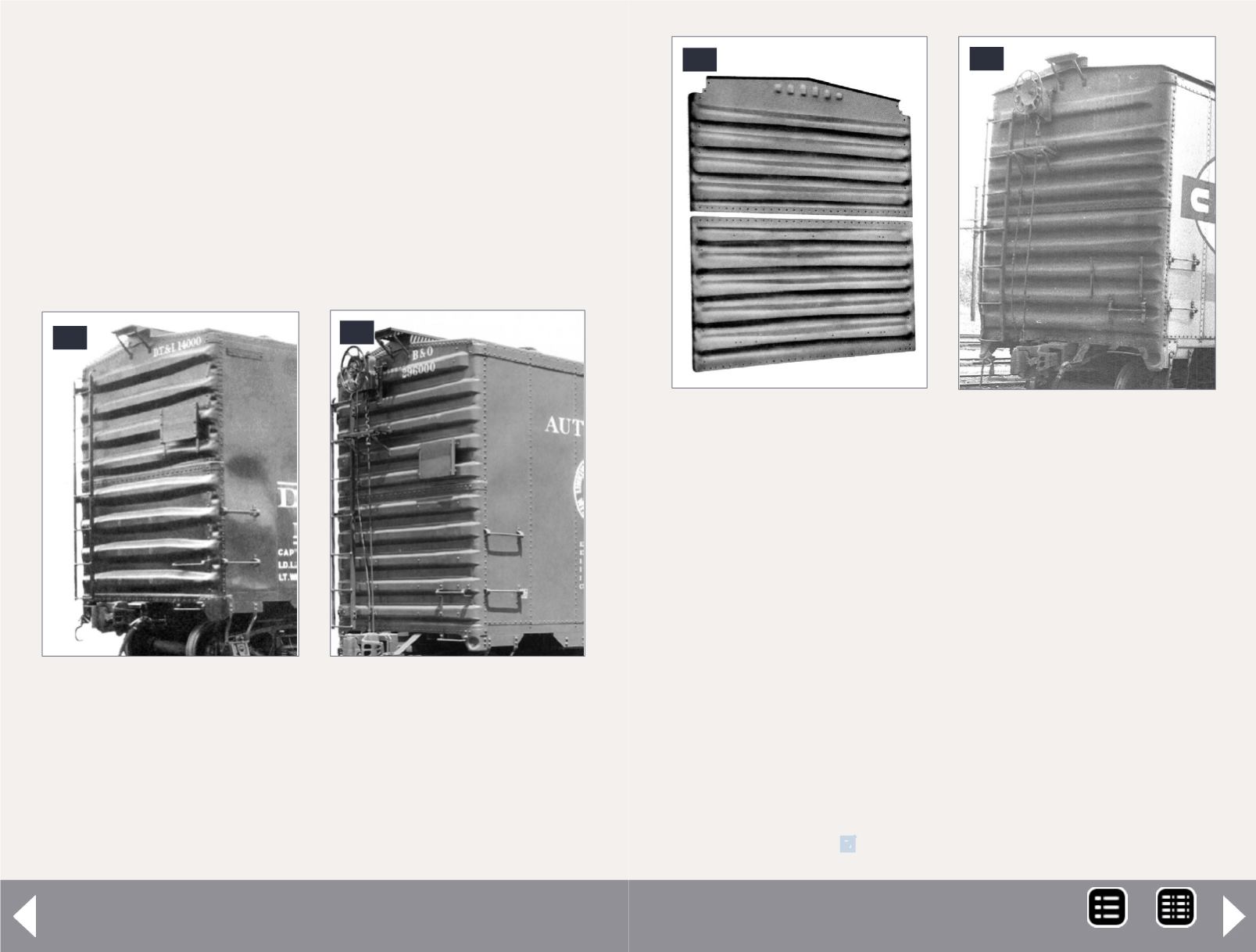

44. Pullman-Standard

promoted this 4/5

steel end in 1953. P-S

frequently identified their

ends with six indentations

in the hat section.

44

45. Proprietary 4/5 end

designed by Despatch

Shops in East Rochester,

NY. Note the truncated

top rib.

45

manufacturing process without the need for specialized tooling

for various car sizes.

Terminating and non-terminating end ribs

defined

A terminating end wraps around the side of the car and is bolted

or welded to the sides [45, 46]. Non-terminating ends are recessed

flush with the corner of the car and are either bolted or welded to

the corner post [48].

MRH-Oct 2014