9

9. My

diamond

sharpener

is 8" long by

2½" wide.

The Tool Shed - 5

absolutely flat resin body covered by an industrial diamond

sharpening surface with an “interrupted” polka-dot pattern

to collect the fines removed during use. While designed for

sharpening tools, they are wonderful tools for filing down

long surfaces such as the floor or underbody casting for a

resin freight car [10], filing the running board supports on

resin house cars so that they are all level [11], and sanding

the back of thin resin castings to remove flash. Rather than

holding a file to do these tasks, the sharpener is positioned

on the workbench and the part moved over it. One of the

advantages of a diamond sharpener is that, unlike a file, it

cuts when moving the part in any direction.

I bought my 8″ DMT diamond sharpener from Woodcraft

. They are available in different combinations

of grit. Mine has a Coarse grit on one side and Extra Coarse

on the opposite side. While these might seem too coarse for

model work, they are equivalent to 220 and 325 grit sandpa-

per respectively. These are made in the USA, and are high-

quality tools. They come with a non-skid mat, but mine works

without it on my self-healing cutting mat. Mine cost $103.00.

They are expensive tools, but really worthwhile if you build a

lot of resin kits.

Disclaimer – I love good tools and don’t hesitate to invest in them.

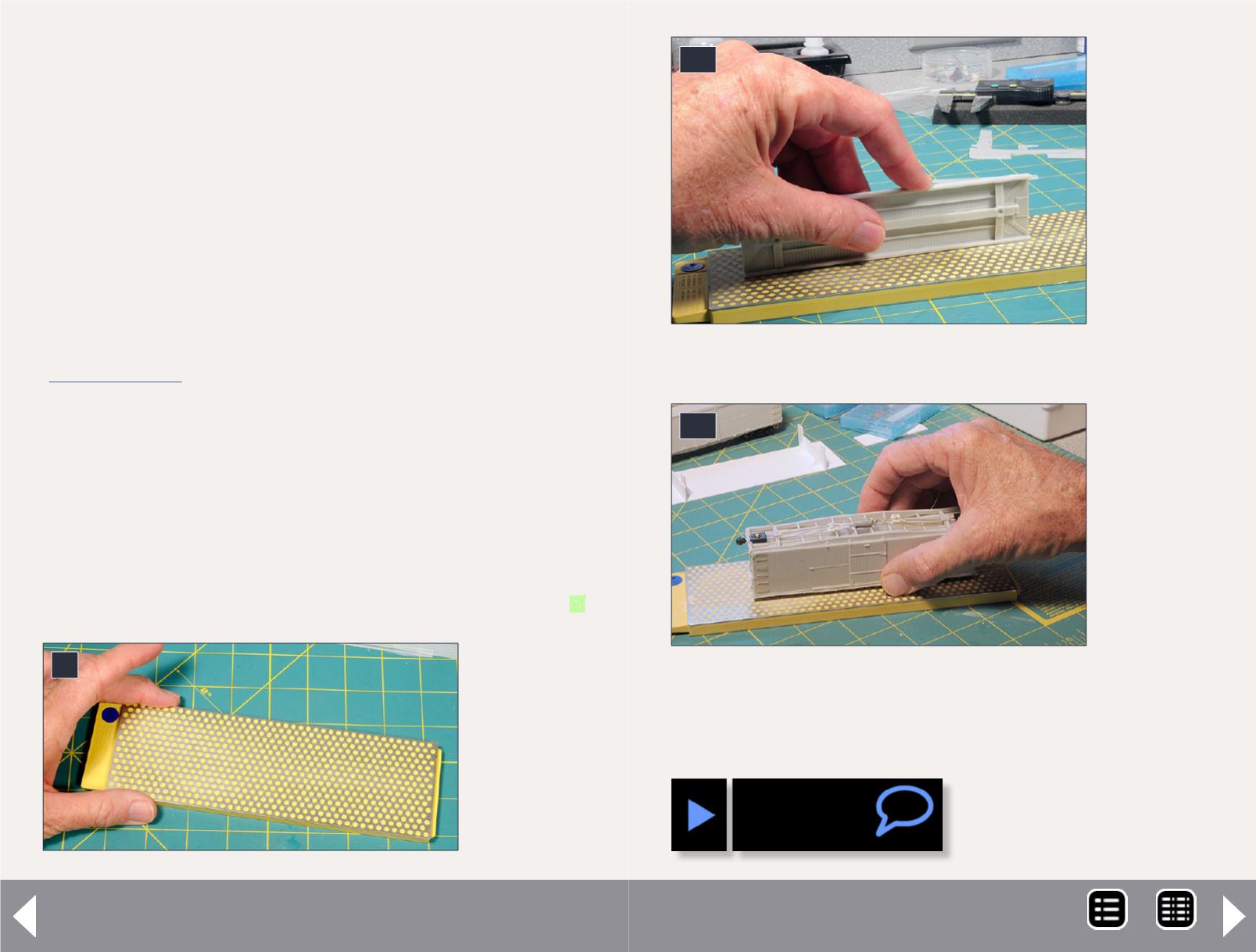

10

10. Sanding

a resin kit

floor using

a diamond

sharpener.

A diamond

sharpener

makes it

easy to

reduce the

width of

the kit floor

evenly over

the length of the resin casting.

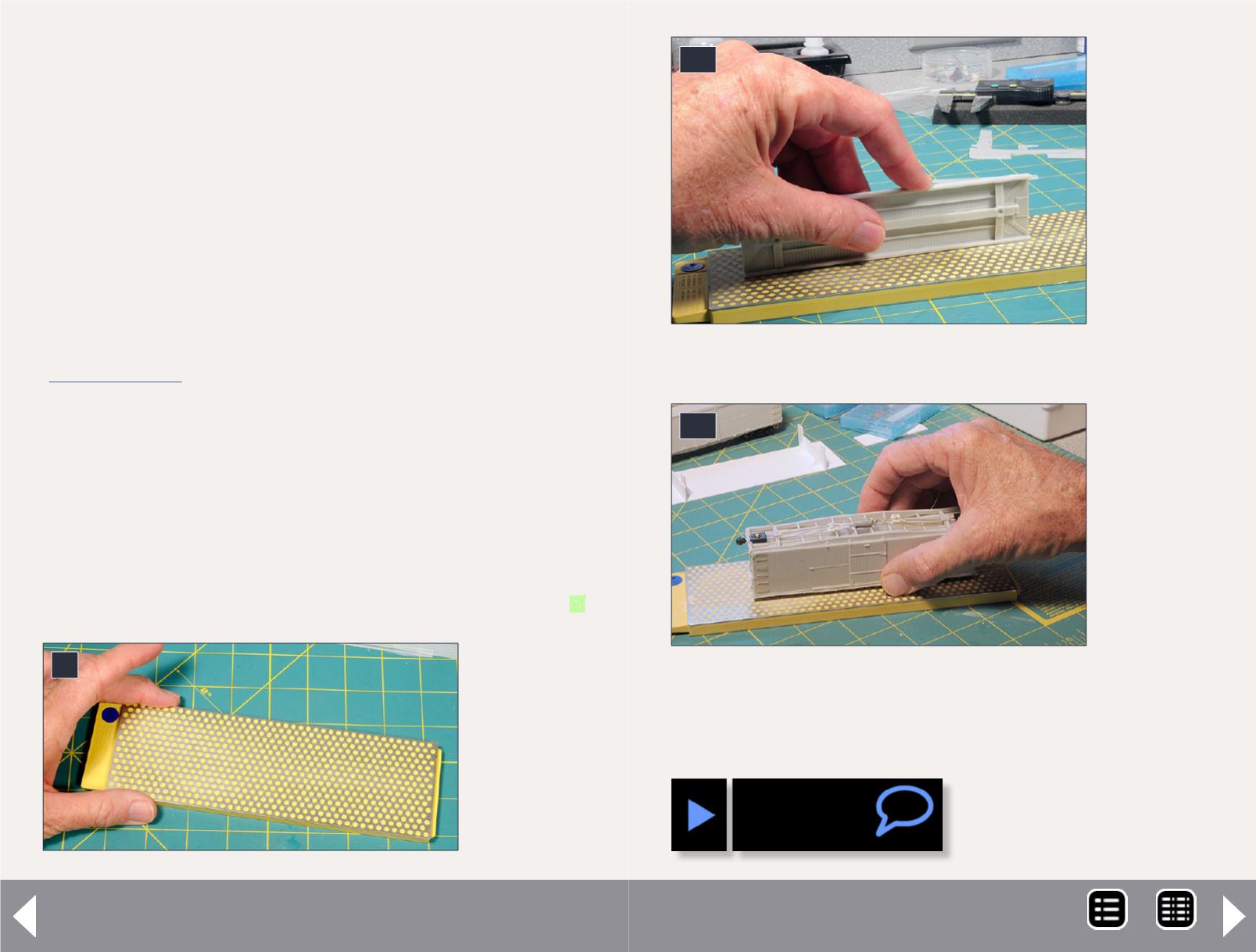

11

11. Making

sure all the

running

board

supports

on a resin

house car

are even

can be

difficult with

a standard

file, since it is hard to keep the car level and also at a right-

angle to the file. Using the diamond sharpener, I slide the car

back-and-forth and know that all of the running board supports

are even when there is resin dust next to each support.

MRH-Nov 2014