What’s neat column - 3

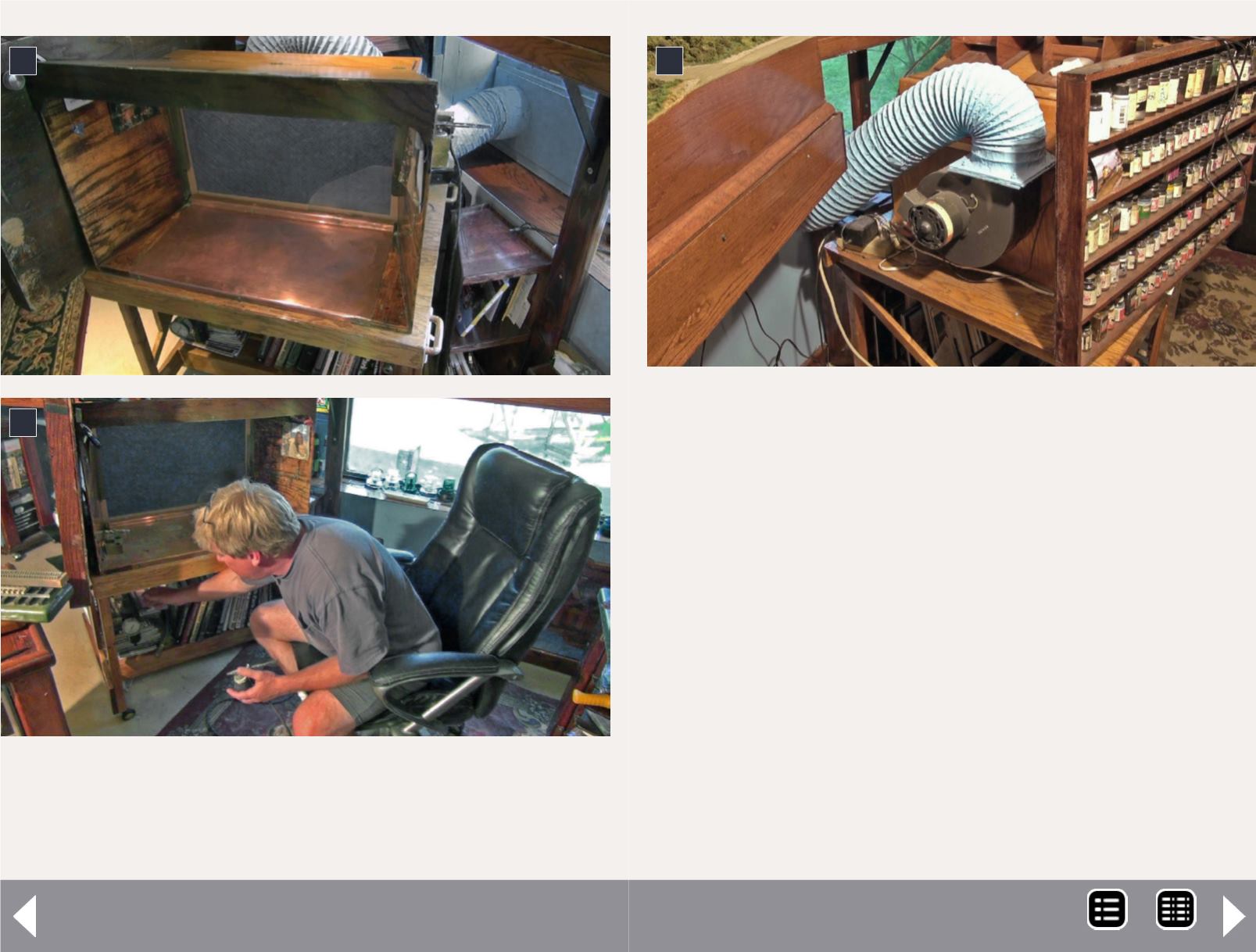

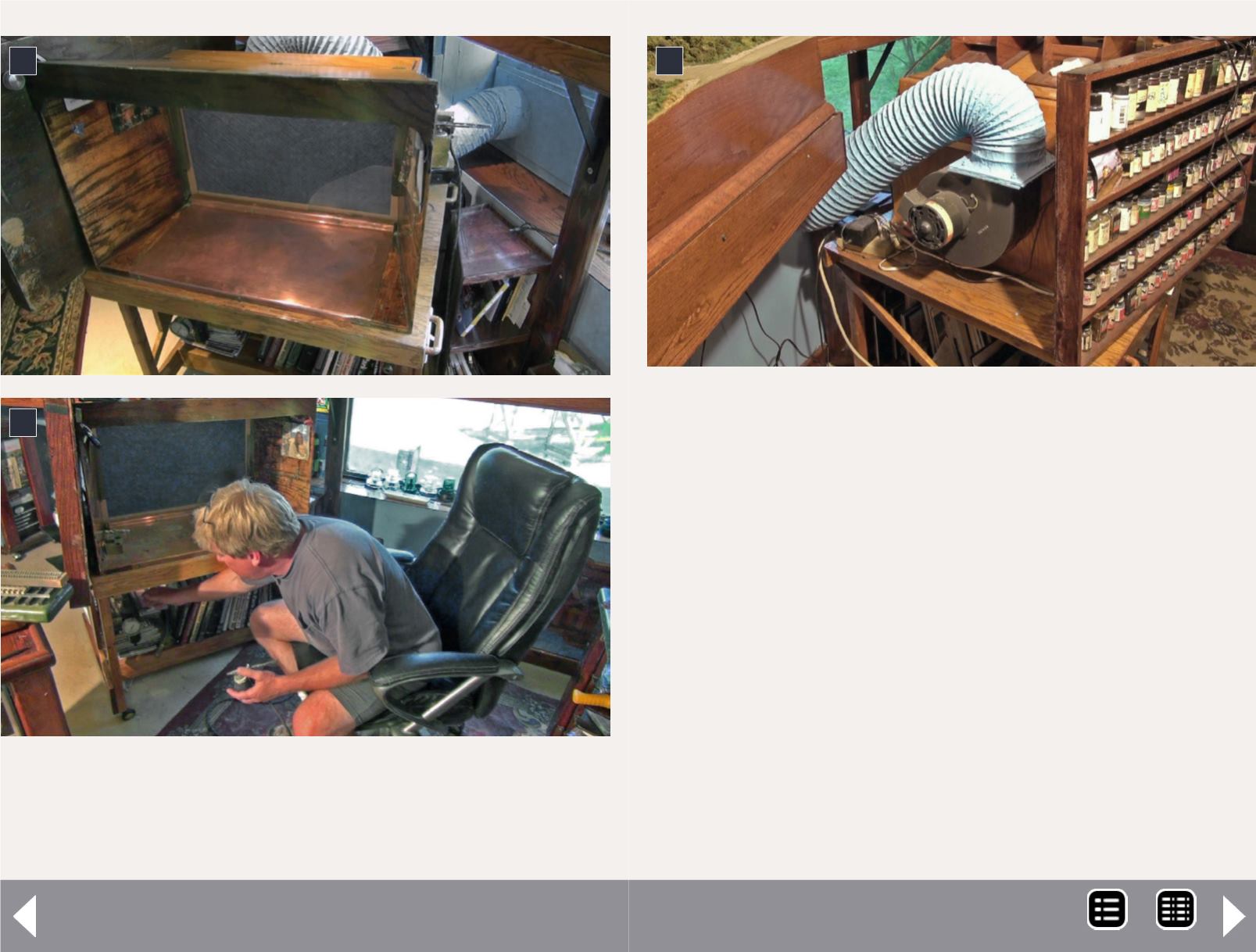

3-5. In another video segment, I discuss the design of my

airbrush painting booth. Using ¾” and ¼” oak plywood made

this booth strong. It is ventilated by a 500 cubic-foot-per-

minute blower motor and squirrel cage blower from Grainger.

3

4

5

This is the second motor. The first one wore out after 15 years

of daily use. Three air outlets are built into the base, with

shutoffs to run various air brushes. Roof-mounted lights cast

bright light on the paint project. A 16 x 24“ air filter slides

in from the top to catch paint particles that could clog the

blower fins and cause air flow to be lost. There is an air dryer

with a regulator and air pressure gauge. Copper ½” tube was

soldered together to run the air from this dryer to the three

outlets that supply air. It is a great painting tool that looks

good in the shop. The polyurethane finish matches the rest of

the decor in the studio. On the video you can actually see it

at work.

MRH-Nov 2014