Questions, Answers & Tips - 2

Ballast profile

Q.

My flex track is mounted on cork ballast but the slope

doesn’t look like it does in train pictures I find on the web.

Did I get the wrong product?

– Ernie G.

A.

Cork roadbed is a perfectly acceptable material for model

track, but your work doesn’t end there. The next step is to

apply ballast, available from companies like Woodland Scenics

and Arizona Rock & Mineral.

There are dozens of how-to articles on the Internet. Search

for “model railroad ballast tutorial” and take your pick.

What the videos and articles rarely tell you is how much bal-

last to apply, and what sort of slope the edges of the finished

roadbed should have. Railroad historians and historical societ-

ies have made this kind of information available, and the pro-

totypical slope is more gradual than what’s usually seen on

model railroads.

2

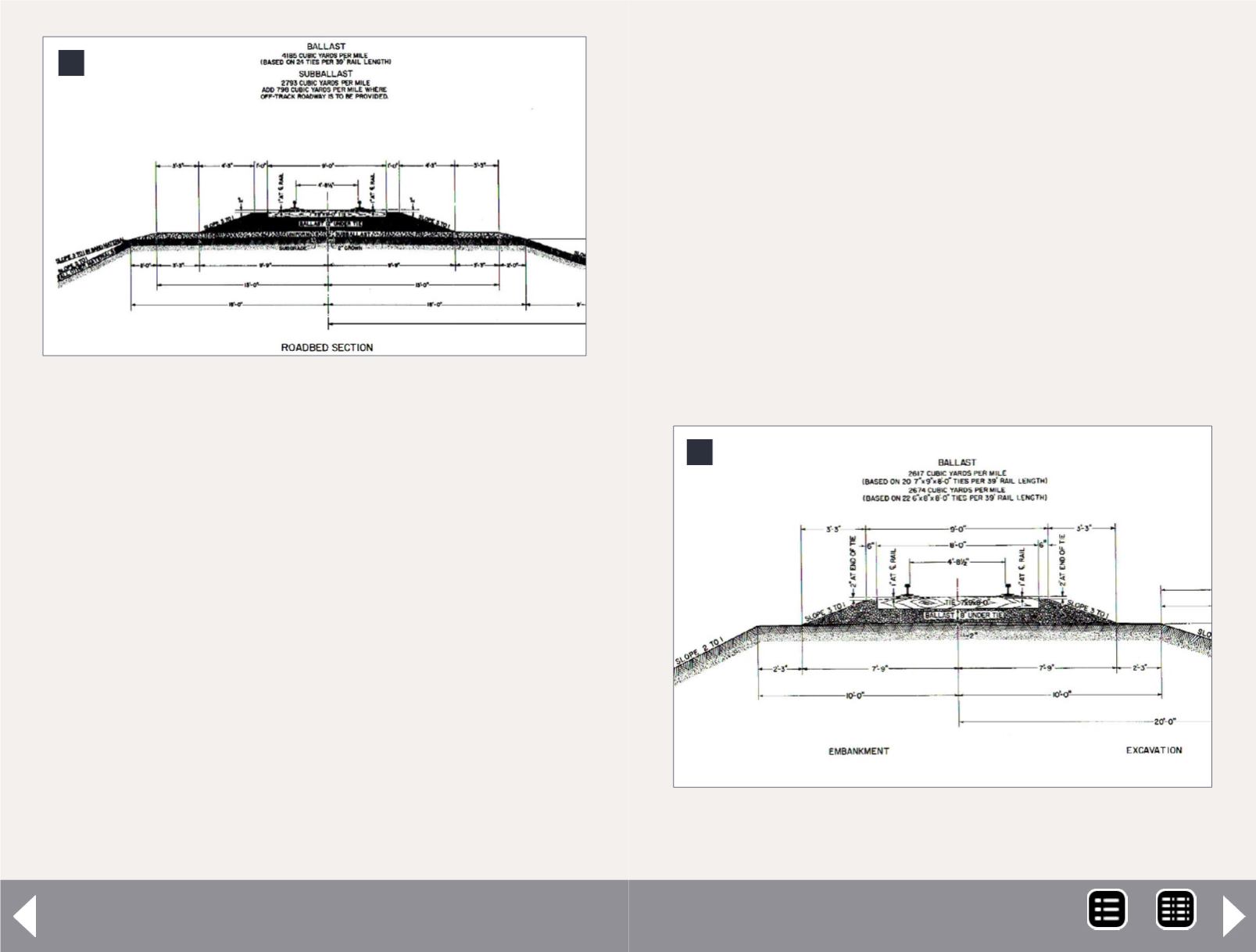

2: A mainline track profile is wide and deep.

3

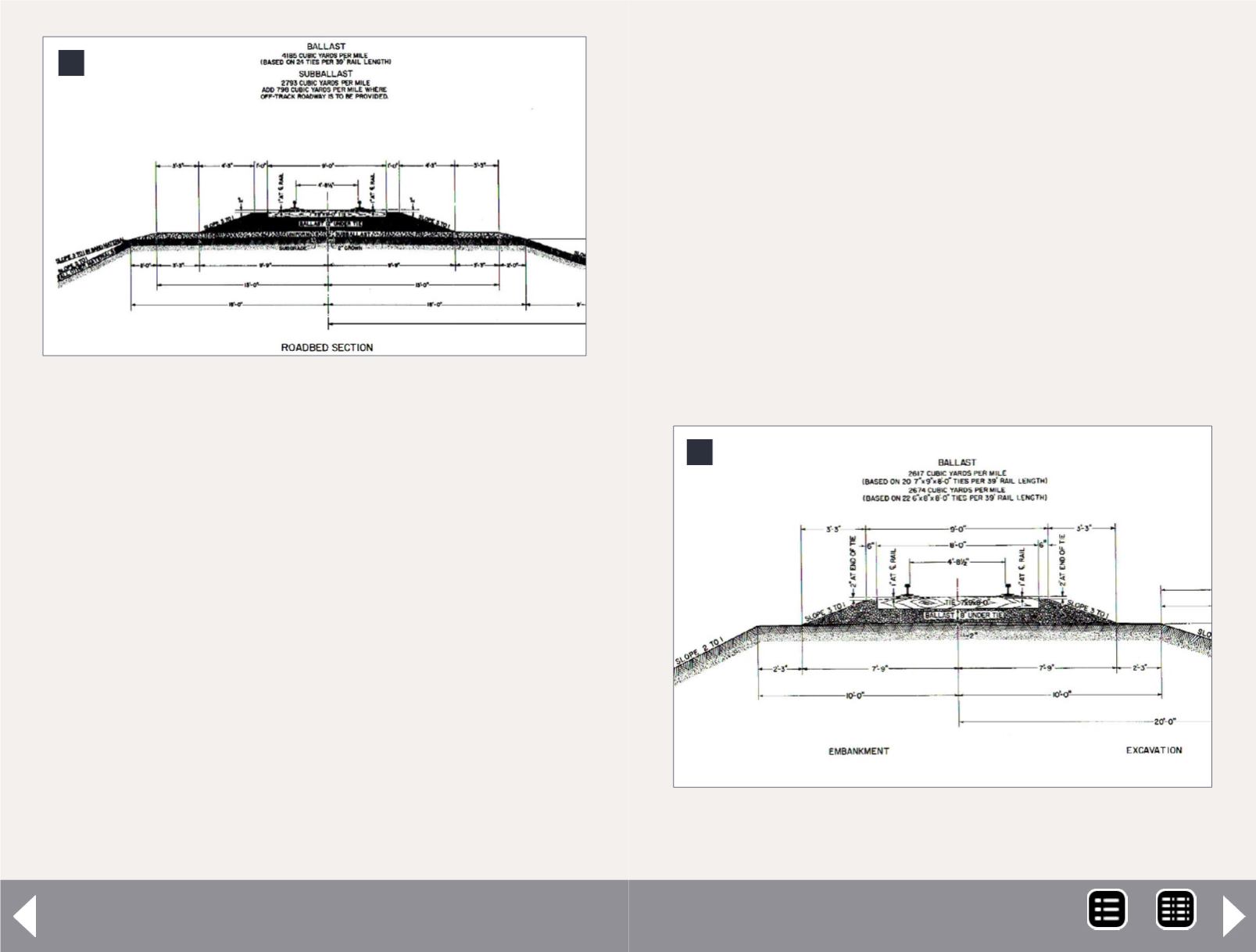

3: Branchline track uses less rock and is rated for lower

speeds.

There are a couple of key dimensions in the main line profile

(2). Note that the ballast should be about 2” lower than the

top of the cross ties, not level with them. The diagram shows

12” of ballast under the ties, and a uniform 6” of sub-ballast

below that. The sides are sloped at 3:1, and the roadbed

extends for a foot on either side of the ties before it slopes off.

Not too many modelers are going to work to those exact

dimensions, but it gives you the proportions of how main line

track would have looked at the time of this 1979 diagram.

A branch line profile (3) is a little different. There is only 8” of

ballast under the ties, and only 6” beyond the end of the ties.

The edge slope is the same, 3:1, and there is still a 2” layer of

larger crushed rock under the bed of ballast. For a point of

comparison, the mainline spec called for 4185 cubic yards of

MRH-Jan 2014