DCC Impulses Column - 3

heat in the amplifier. This added heat can damage or destroy

the decoder, depending upon the amplifier design.

Higher impedance (say 16 ohms) will reduce the load on the

amplifier, but the amplifier may not be able to push as much

power into the lower load: 3/4 watt into 16 ohms would be

a common result. Generally, higher impedance loads are not

harmful to the decoder; you just reach a point where the

diminished audio power isn't compensated by the increased

efficiency of adding more speakers.

I recommend checking with the decoder manufacturer before

you contemplate any impedance other than the rated load, be

it a single value or a range

of loads.

Heat

Be aware, as we make

smaller and more power-

ful (both electrically and

feature-wise) decoders,

heat generated inside the

decoders becomes more

of an issue. How the heat

will get out of the decoder

should be a design cri-

terion in every installa-

tion. With small sound

decoders, it becomes very

important. If you are con-

templating pushing the

envelope on load imped-

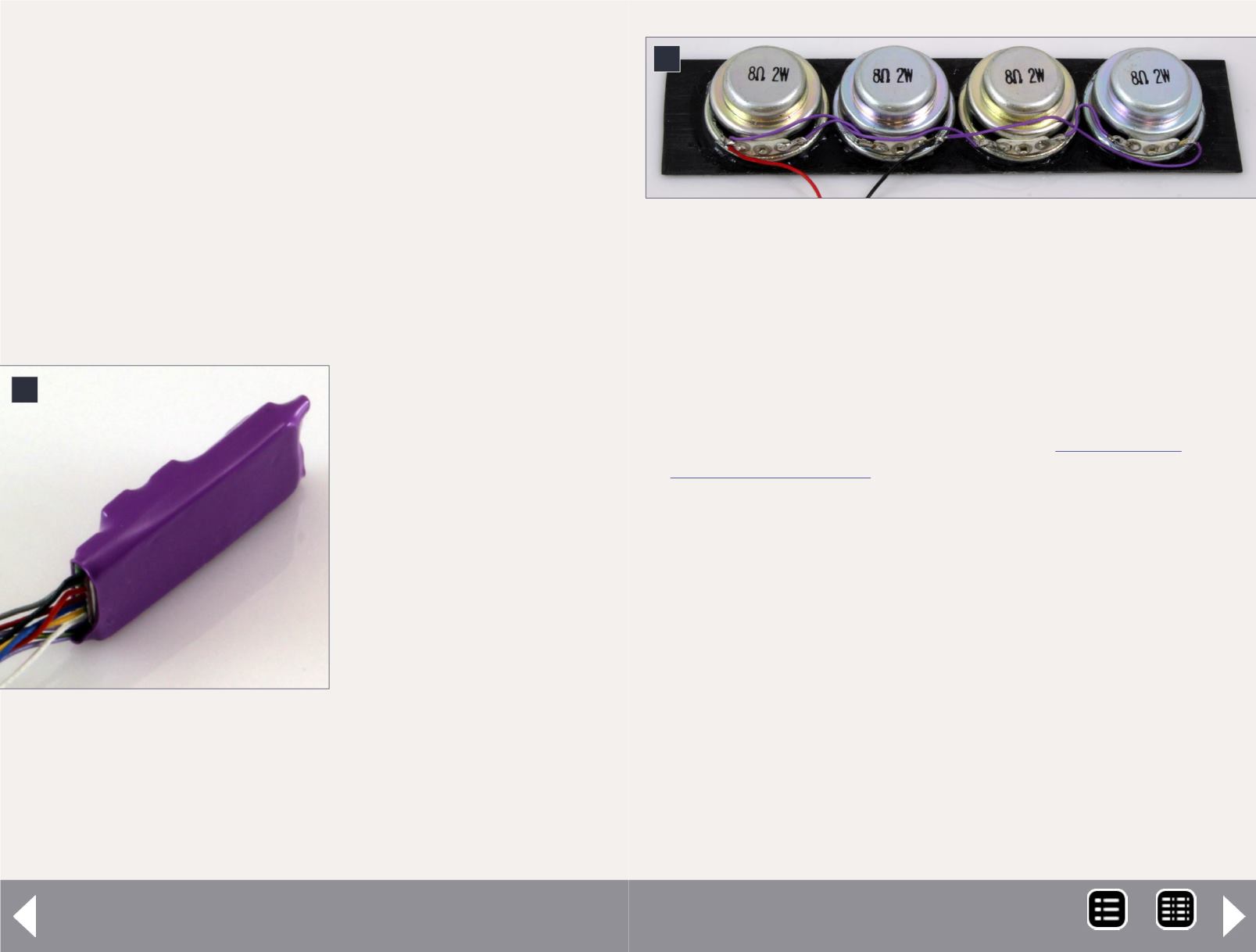

4: Line array of four identical speakers - wired in a series-

parallel combination, the resulting unit is rated at 8 ohms

and 8 watts.

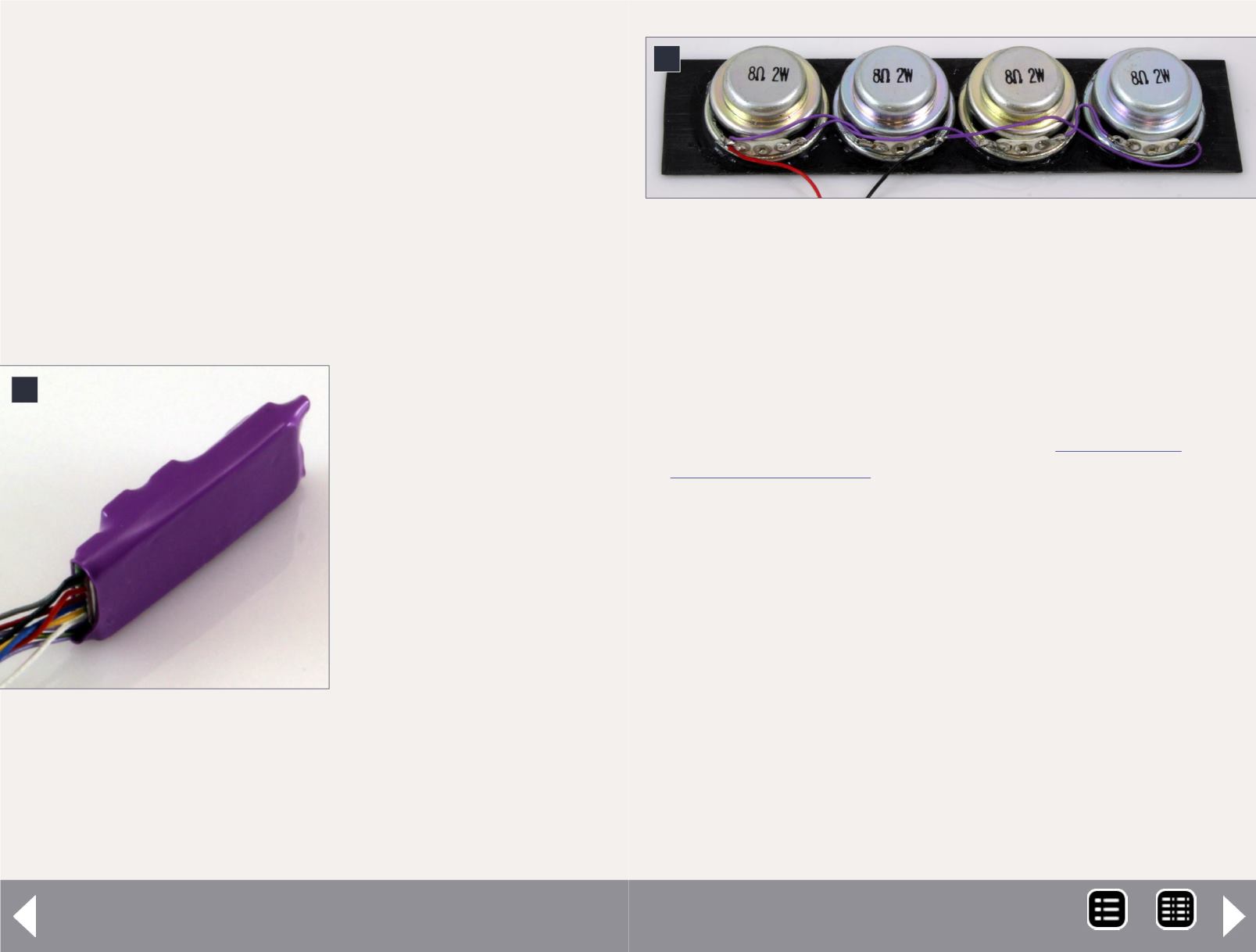

3: TSU-750 Micro Tsunami,

showing flat side where the in-

ternal heat sink is located. This

should be attached to a metal

surface to remove heat from

the decoder.

3

ance (4 ohms on a decoder rated for a nominal 8 ohms), then

heat may become an even bigger issue.

Figure 2 shows a mounting plate for a TSU-750 micro Tsunami I

built out of brass sheets held together with thermally conduc-

tive epoxy (see my December 2012 column -

. Brass sheets (0.032” thick) were cut

to the size of the top of the frame where the driveline went

between the motor and the front gear tower. They are stacked

up until they are tall enough to clear the gear tower at the

limits of its height when pivoting and swinging. Then a single

sheet is glued extending forward to provide a decoder mount-

ing location. In the photo, a bit of white epoxy is visible where

the decoder mounts. I had previously mounted a decoder on

this stack, and removed it by light prying. The Alumina Thermal

adhesive broke cleanly away from the decoder shrink tubing.

A dab of thermally conductive epoxy and the decoder will be

back in place – flat side against the brass plate.

So how does this work? The components inside the decoder

that need to be cooled are connected through thermally con-

ductive foam to a metal plate that is held in place with the

4

MRH-Jan 2014