Switch machines on foam - 1

T

he introduction of using two-inch extruded foam as

the main foundation for track has certainly helped

lighten many a module, and also allowed the modeler

to more easily sculpt scenic contours below the track grade.

Foam has made things easier, but presented a new problem:

mounting electric switch machines.

The obvious and simple solution is to use small blocks of

Masonite and glue them to the underside of the foam. This

solution presents several pitfalls. First, when building mod-

ules, it's best to keep the switch machines recessed inside for

fold up legs, as well to minimize potential damage when being

moved. Second, depending on the adhesive, the likelihood of

Installing Electric Switch

Machines on Foamboard

A simple technique for

reliable installation ...

– Chris Palomarez

Photos by Harry Wong

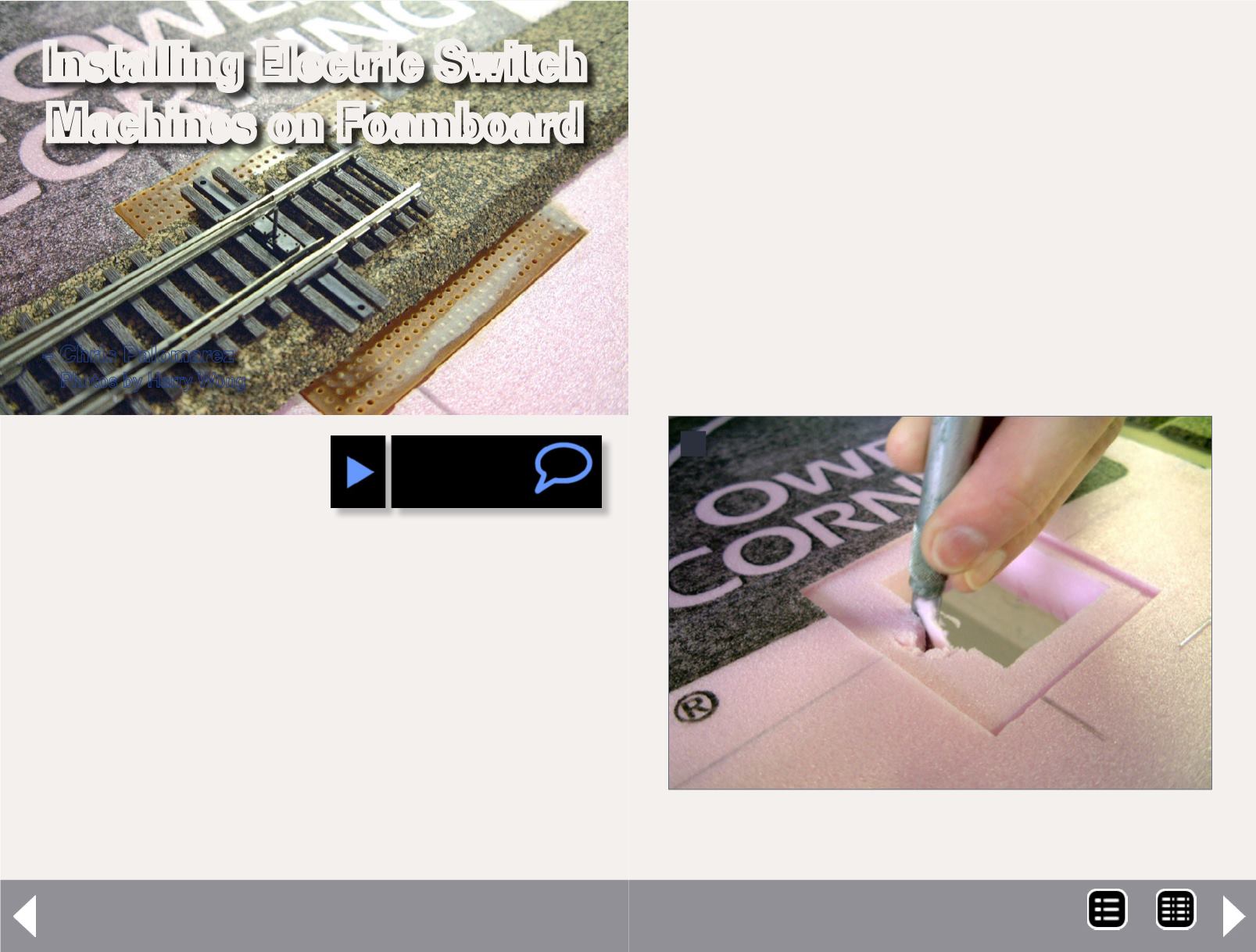

1: After turnout and the throwbar is located. A square

hole and recess is cut in the foam.

1

the bond failing increases the more the module is transported

and encounters heat/humidity fluctuations. Third, and a per-

sonal pet peeve, are excessively long actuator wires.

A different approach was required to account for these

potential pitfalls. In Free-mo, there was a lot of interest in

keeping the modules light and quick to setup. This meant

switch machine installations needed to be installed from the

"top down" rather then from the "bottom up" with plywood.

In early 2000, Brian Kreimendahl, and I developed this solu-

tion for a module set he was constructing. His modules were

substantially larger than 24", with a 42" total module width.

Foam module tops were a necessity to keep the weight of

each section manageable. We used initially single-sided cop-

per clad circuit board, but then graduated to using perfed/

MRH-Nov 2013