STEP 11: Making Rubber Molds and Casting the Parts

Continued ...

The Erie Railroad Boxcars Part 3 - 12

48a: I have not

seen the Smooth

Cast products in

a big-box store

like Michael’s. If

you can’t find the

product locally,

it can be ordered

online. The

website is

In addition

to product

information, they

also have tutorials on the website.

I found what works best for me is to begin

pouring slowly in the center of the mold and

allow the casting liquid to migrate to the edges

of the mold. If there are any little gaps that have

not been filled, I pour a little more of the liquid

into the areas that needed to be filled. I also get

down and look across the mold to make sure

that I am not overfilling it. If I do, there are only a

few seconds to use the stir stick to pull away the

excess material.

While the instructions say you don’t have to

worry about air bubbles, I have found that

you occasionally get them. The first bubbles

I experienced, I tried to fill in with Squadron

Green filler. That was a bad idea! I quickly found

that it does not work with this product. There is

48a

STEP 12: Detailing the Sides and Ends

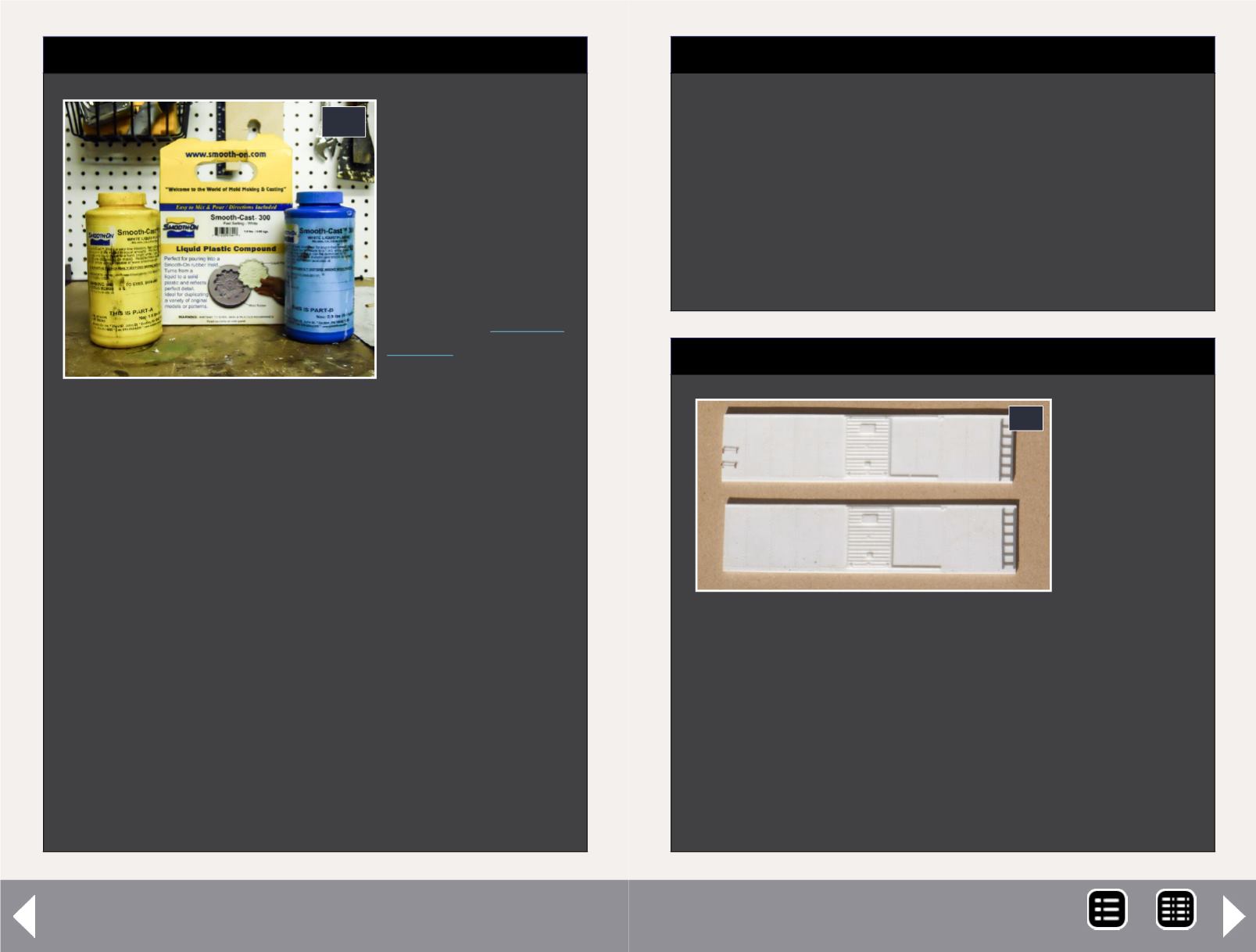

49: I had

one of those

“ah ha”

moments.

Why not

detail, paint

and decal

all of the

parts before

they were put together? It made sense, and I hate

masking cars. I wouldn’t have to worry about

damaging any of the detail that invariably seems

to get maimed when I pull the masking off.

It also would be easier to decal the cars with the

individual pieces lying flat. All I would have to do

is be careful assembling the cars. There are some

detail pieces would need to be added after painting,

but those could be touched up with a small brush.

49

STEP 11: Making Rubber Molds and Casting the Parts

Continued ...

a reaction that destroys the shape of the area

around the filled area.

The best method I found is to use small bits

of styrene held in place with a gap-filling ACC

cement. The other option is to cast a new piece.

My hat is off to those who make castings like this

on a regular basis.

MRH-Jun 2013