the coal movement would

be from right to left. A

conveyor originating in

an underground mine

is a new addition. I kept

the run-of-mine coal rail

delivery operation from

coal tipples located on the

layout, as well as trucked-

in coal from nearby strip

mines. Another important

addition was increased rail

capacity for inbound run-

of-mine coal, and sepa-

rate trackage for loading

unit trains. The previous

track arrangement had

two tracks for run-of-mine

coal unloading and unit

train loading. There was

not enough room for either operation, plus the two operations

could not be accomplished at the same time.

I begin a coal load-out project, or any other aggregate opera-

tion, at the rail loading point, and work back toward the main

complex. For starters, I use some basic clearance dimensions

for the type of railcars that will be loaded/unloaded. 100-ton

hoppers are 12.5’ high from the top of the rails while 55-ton/

70-ton hoppers are 11’ high from the top of the rails. Peaked

ends generally bring the height of these cars to 12.5’. These

dimensions determine the height from the top of the rails to

loading chutes or other equipment that may be over the rails.

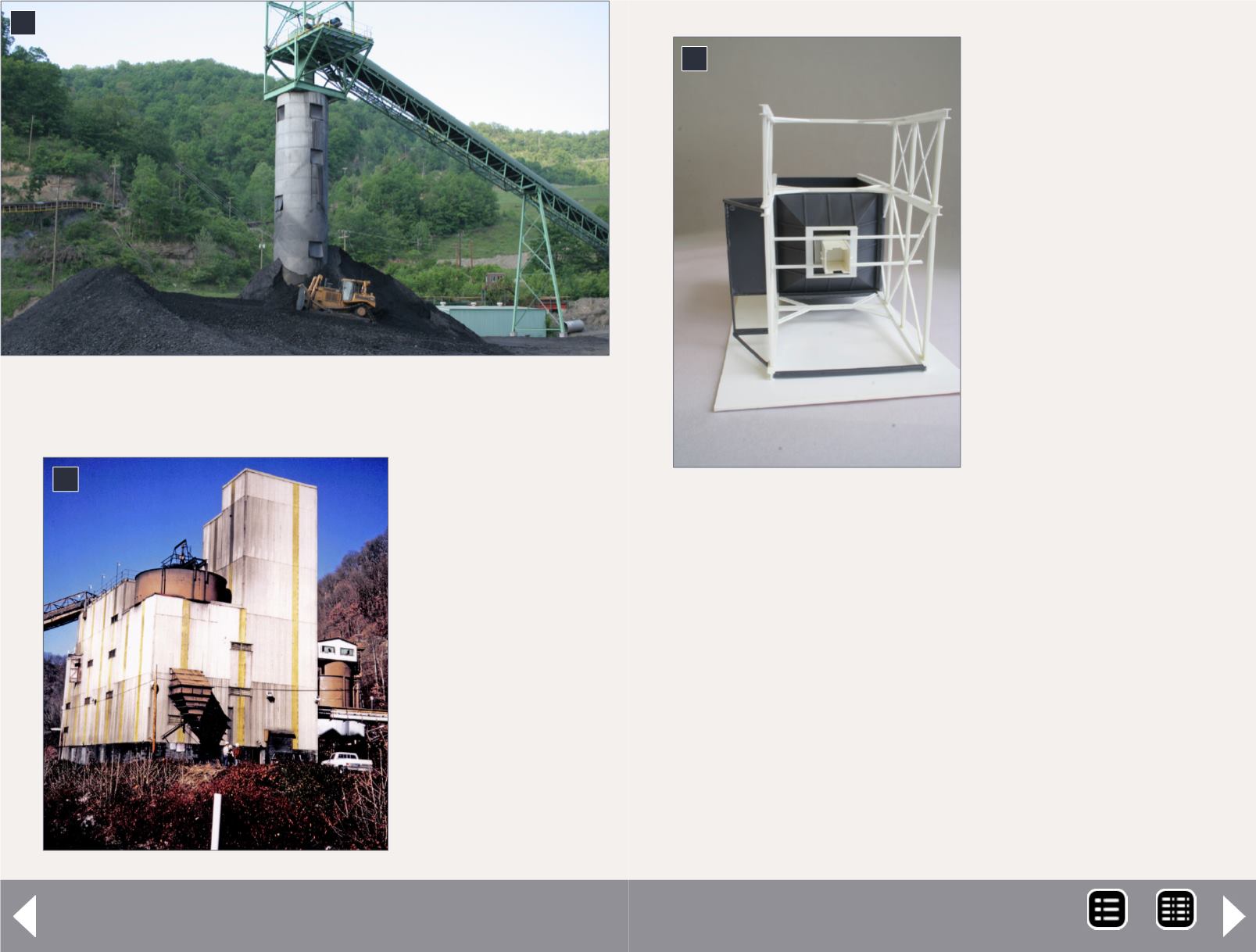

4. Bulldozer working ICG’s coal stacker preparation

plant near Raven, KY.

4

The Wheeling-

Pittsburg Steel

coal preparation

plant near Omar,

WV. This photo

was the basis

of the main

preparation plant

on my layout.

5

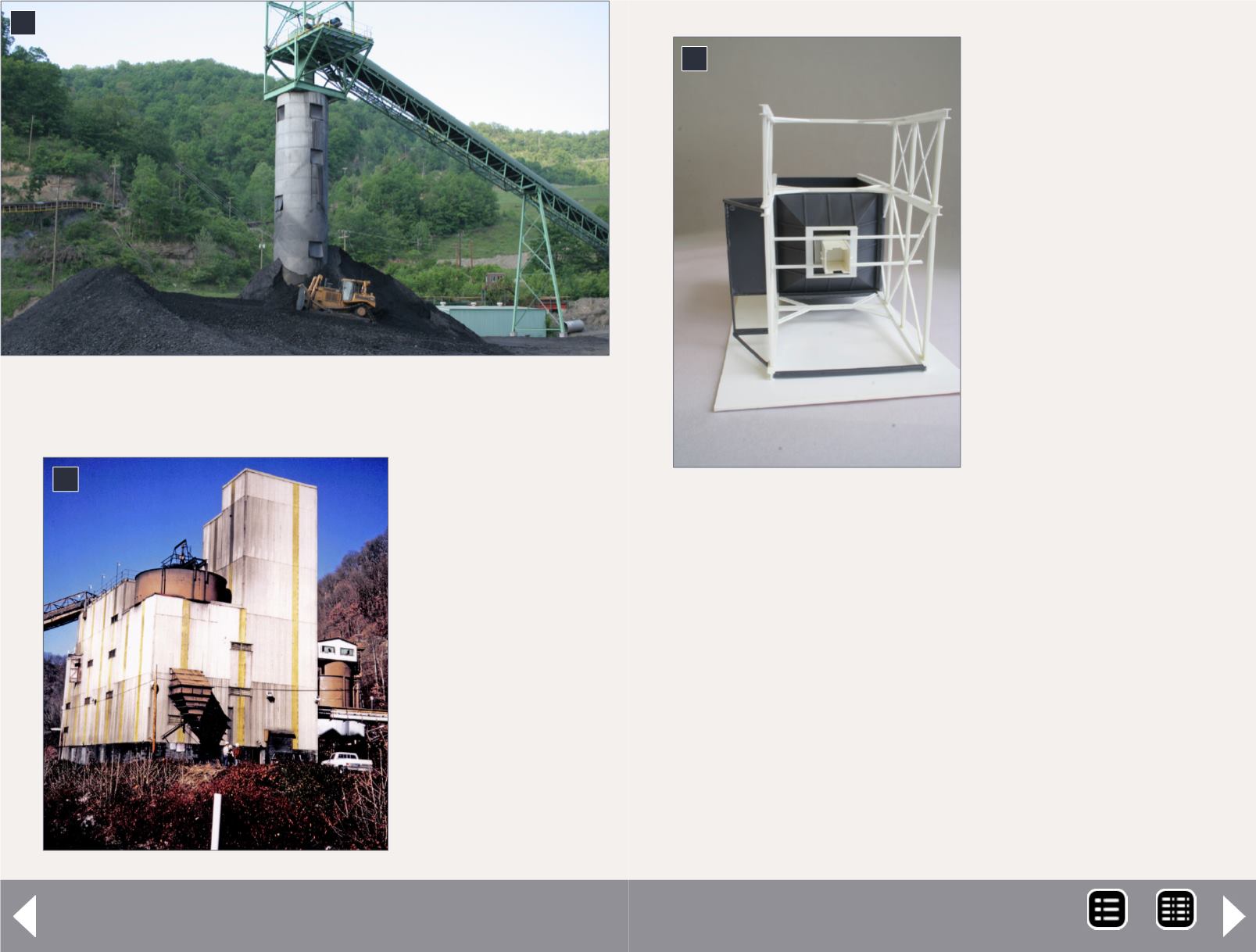

Fast loader - 3

6. Reworked Walthers Flood

Loader kit.

6

MRH-Dec 2014