70, 83, and 100 rail that holds ME rail ends in precise align-

ment. They’re also small – good if you care about the appear-

ance of your track.

I use Atlas joiners if I need to connect Atlas and ME rail.

Forcing wider Atlas code 83 rail into a ME joiner usually

causes the rail joiner to split. I carefully hold the ends of the

rail in horizontal and vertical alignment with tweezers when

soldering these joints.

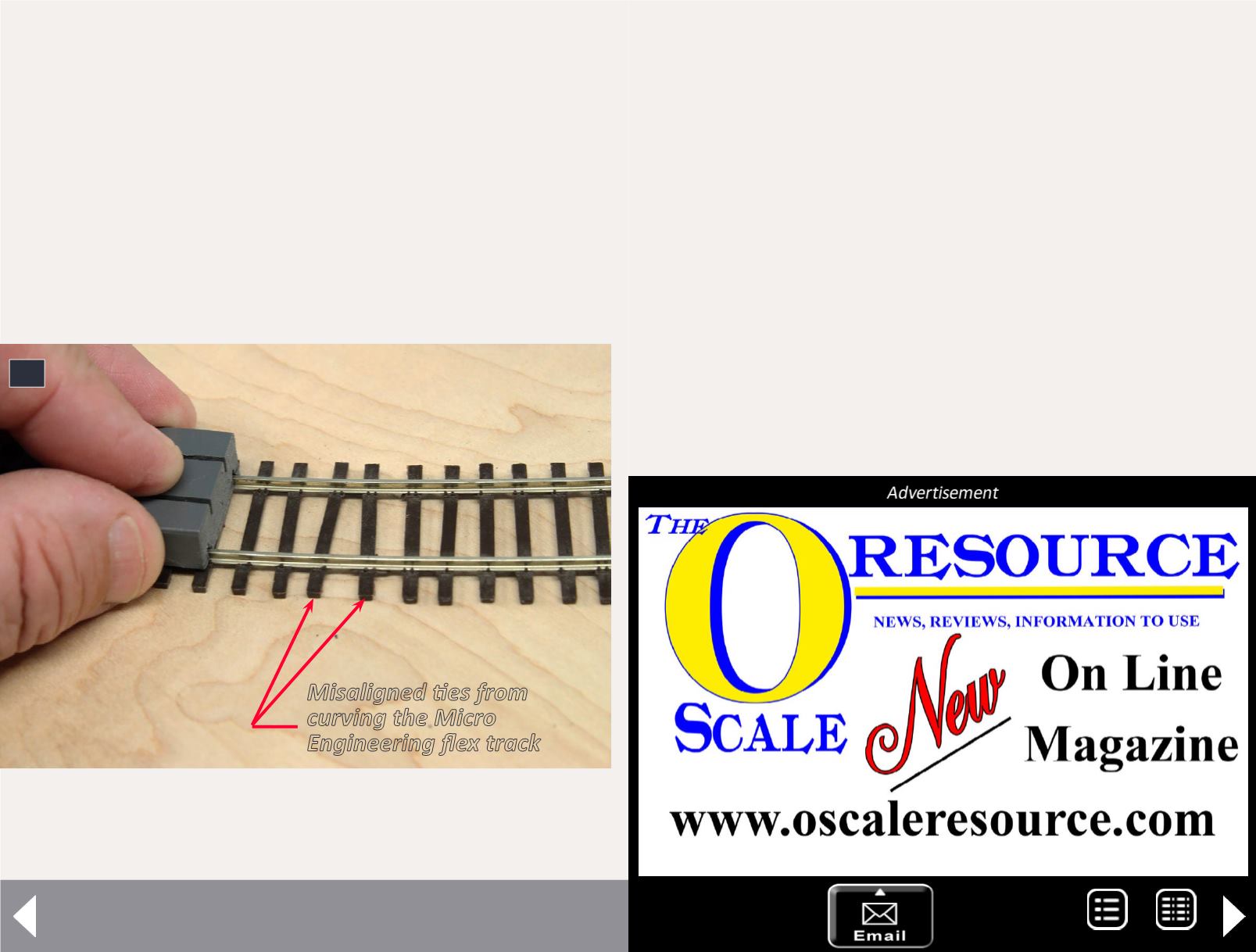

10. Curving ME track often results in the ties losing

position and becoming misaligned. I work the ties back

into alignment once the track is laid.

10

Misaligned ties from

curving the Micro

Engineering flex track

Up the Creek Column - 8

Dealing with out-of-place ties

Curving the flex track most likely left the ties spaced unevenly

[10]. I run a blunt instrument such as the non-working end of a

set of tweezers along the ties, snapping it over each one. This

gradually moves the ties towards the desired alignment. If a tie

doesn’t cooperate, I nudge it into position. This sounds harder

than it is. It doesn’t take long to get the hang of it.

With the rails trimmed and rail joiners holding the rails in

place, I mark the cork where the ties stop at both ends, and in

the middle. These marks let me know how far to spread the

caulk I use to hold the track in place until it’s ballasted.

Feeder wires

When installing a double piece of track, I mark the location of

the central rail joiners. If I’m not installing a 6’ double piece of

MRH-Sep 2014