Up the Creek Column - 3

After a week of doodling tracks and industries on plywood and

collecting mostly constructive criticism, the track plan was as

complete as it would get until track laying commenced. During

a work night we double checked that turnouts weren’t located

with their points directly above joists – a problem when install-

ing switch machinery under the track. After a clean bill of

health, we glued the 3/4" plywood joist risers in place, then

screwed down the roadbed.

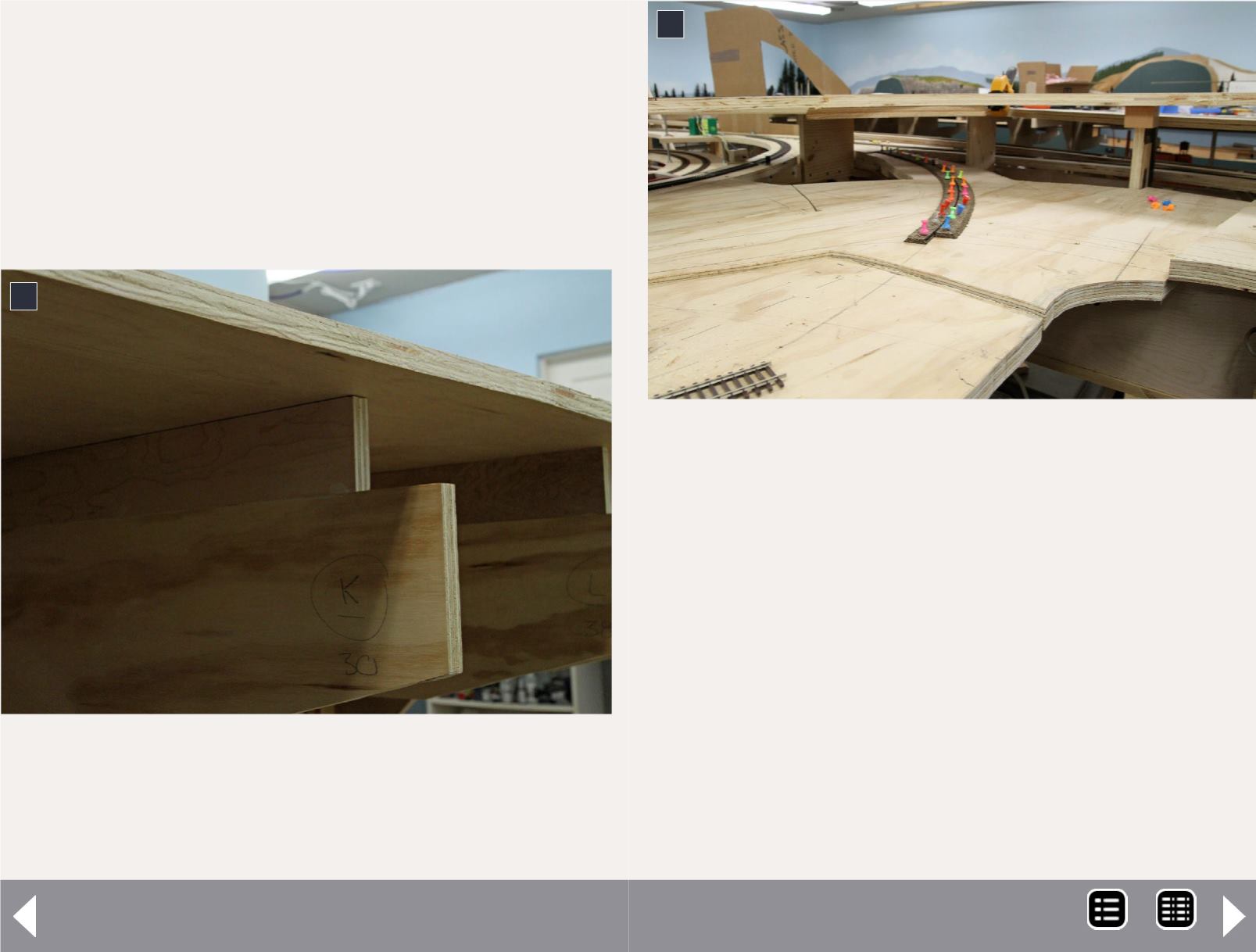

3. 2-3/4” auxiliary joists riding on top of the Browning

supports raise the plywood sub-roadbed to the correct

height. They’re attached with Liquid Nails. I set the aux-

iliary joists back from the edge to make room for a creek

which will border the fascia in places.

3

4

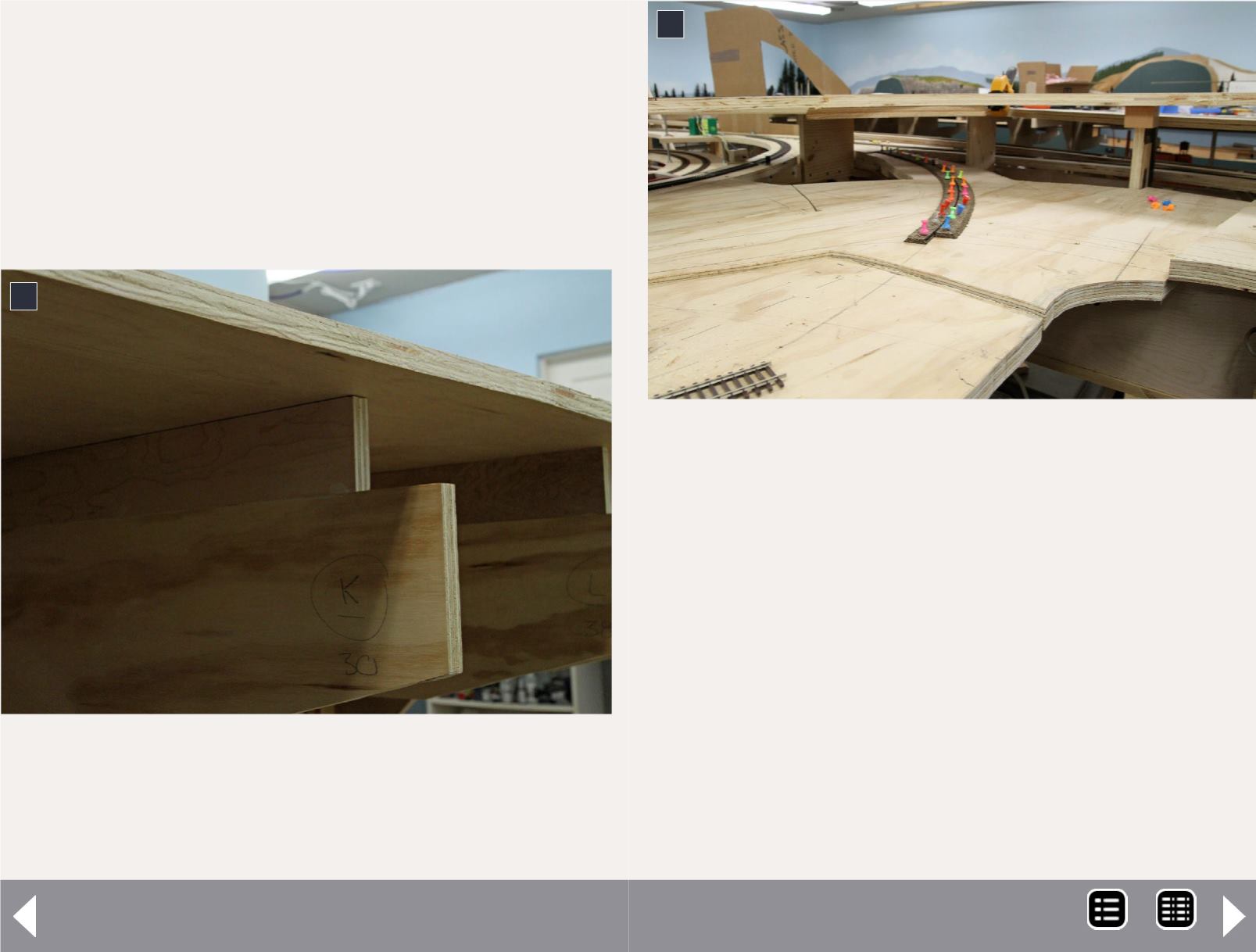

4. I dislike installing cork roadbed and track in a cave. So

I installed lower-level elements before installing the main

line between Bear Creek and Oakhill. This area looks a

lot different with the backdrop in place and painted.

I’d installed a couple of pieces of flex track leading from TOH

Junction (Top Of Helix) to Browning back in 2013. A month

later, this track was covered by the main line and Siskiyou

Branch roadbed and track. Now, in July 2014, it was time to

extend it into Browning.

I usually use 1/4" (actually 5mm) cork under the BC&SJ main-

line. I started laying it where the lead to TOH Junction poked

out of the backdrop [4]. In short order, this will be topped

with Micro Engineering track. I use code 83 for the mainline

and code 70 for the siding. In the past I would have used code

55 for spur tracks but those turkeys quit making the stuff! I

MRH-Sep 2014