Up the Creek Column - 7

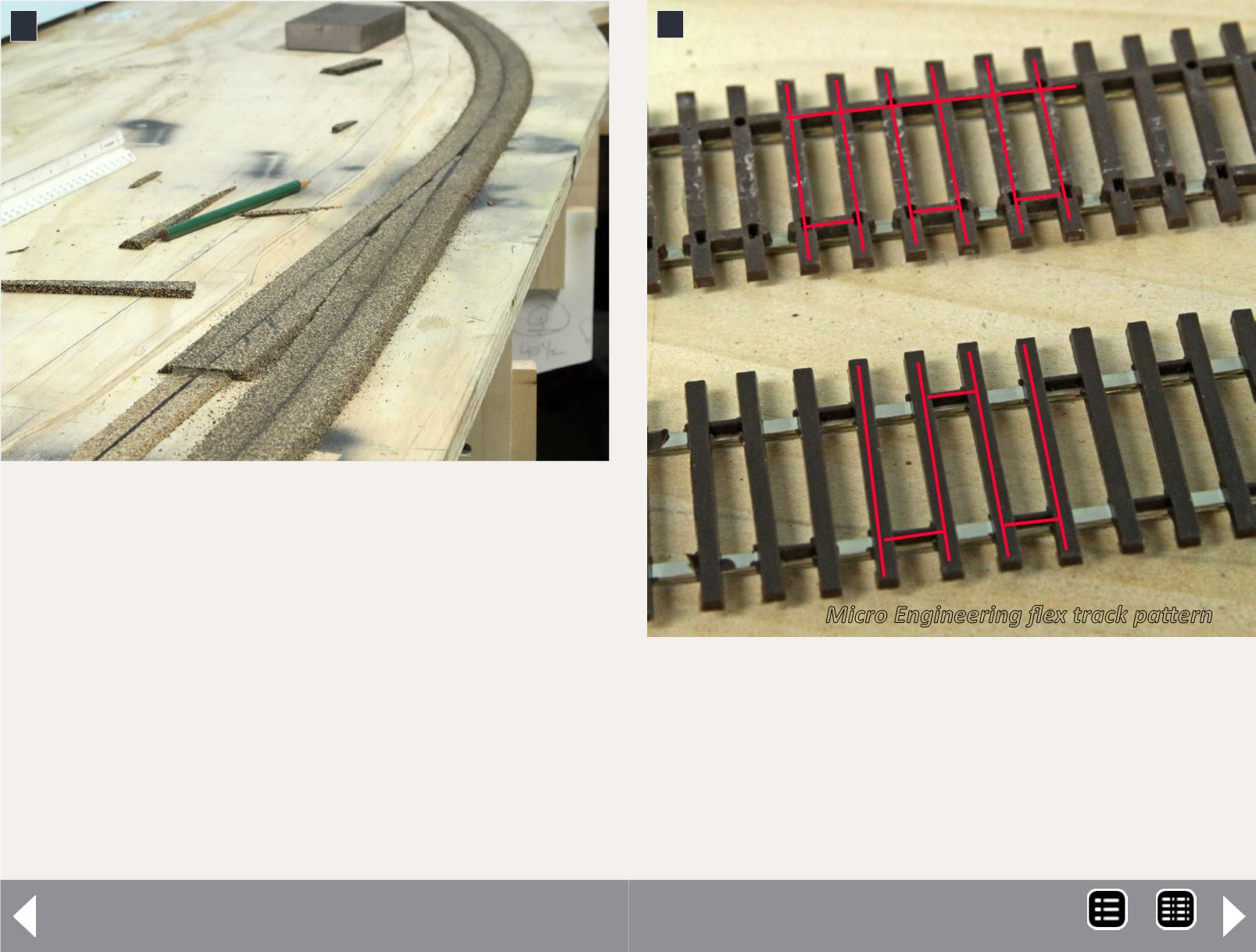

8. The center seam in the cork roadbed is clearly visible

even after the cork has been sanded.

8

I like to solder two pieces of flex track two pieces of flex track

together – 6’ long double pieces reduce the number of unsol-

dered rail joints. I work on a 6’ piece until I get it curved to

approximate shape. Then I put it in position and use the center

seam or a track center line as a guide and tweak it into shape.

I line up the new track with any previously laid pieces and work

on getting the rail ends to mate smoothly. I almost always need

to do some trimming. I use flush cutting nippers to cut the rail.

Cutting with nippers always leaves sharp edges behind. I care-

fully file these smooth. If I don't, the tight-fitting ME rail joiners

hang up and refuse to slide over the rail ends. If this process is

hard to visualize, check out the video accompanying this article.

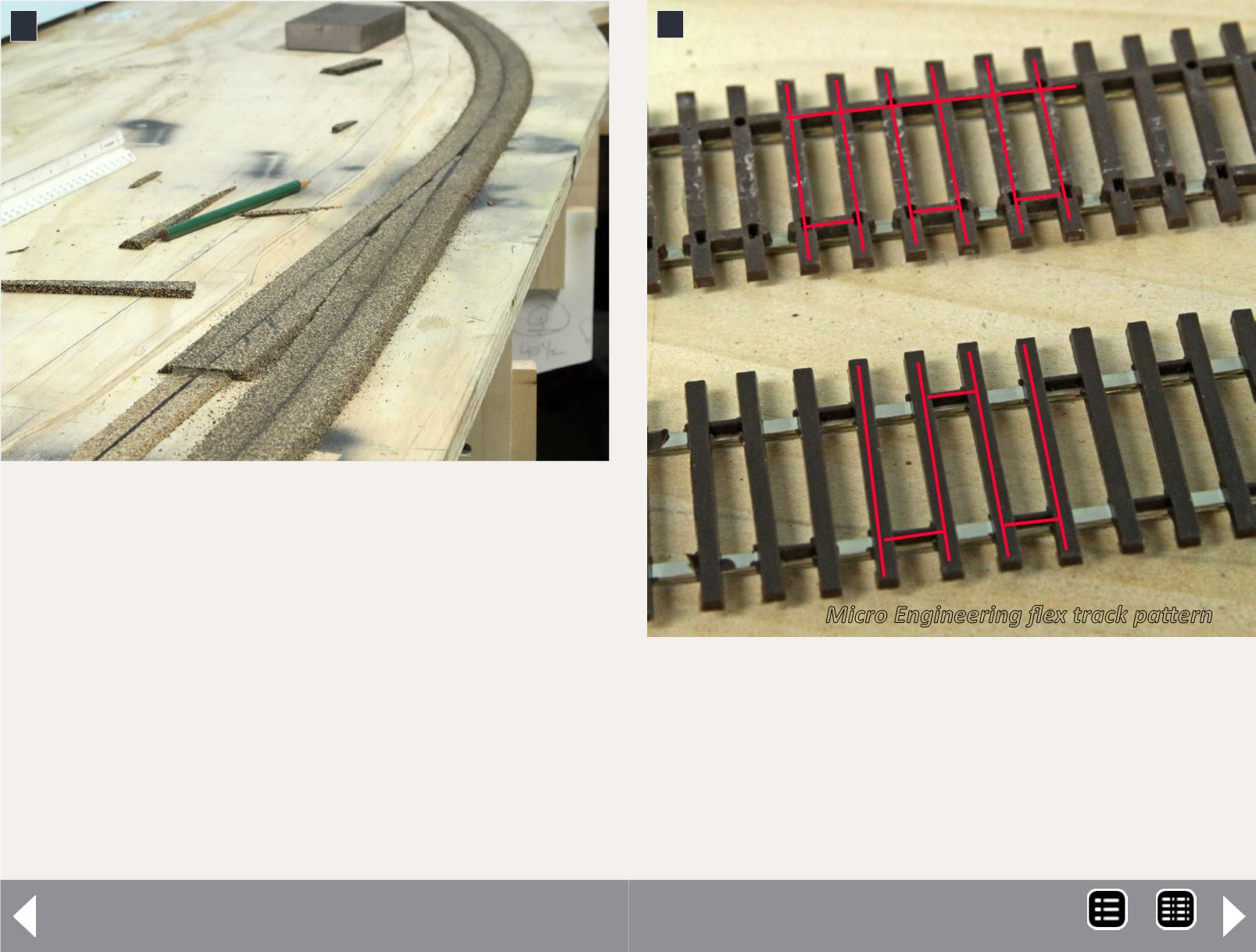

9. Note the different tie patterns of Atlas and ME flex

track. Atlas track is designed to curves smoothly but

won’t hold its shape. ME track is trickier to curve

smoothly but once curved holds its shape.

9

Atlas flex track tie pattern

Micro Engineering flex track pattern

ME rail has a thinner cross section than Atlas, one of the rea-

sons I like it. ME track tends to swim around inside Atlas join-

ers. Micro Engineering sells HO rail joiners sized for code 55,

MRH-Sep 2014