approaching and moving on curves and where view is

obscured, looking out carefully at all points for track cars and

men working on track without flag protection ...

In other words, the section gang will be working somewhere,

and if your train is not on the timetable, they have no idea

you’re out there. The instruction also calls for frequent whis-

tling of the - 0 - grade crossing signal in the same situation.

As a help to crews, new instructions in each edition were set in

italic type to make them easy to see.

– MRH

TIPS

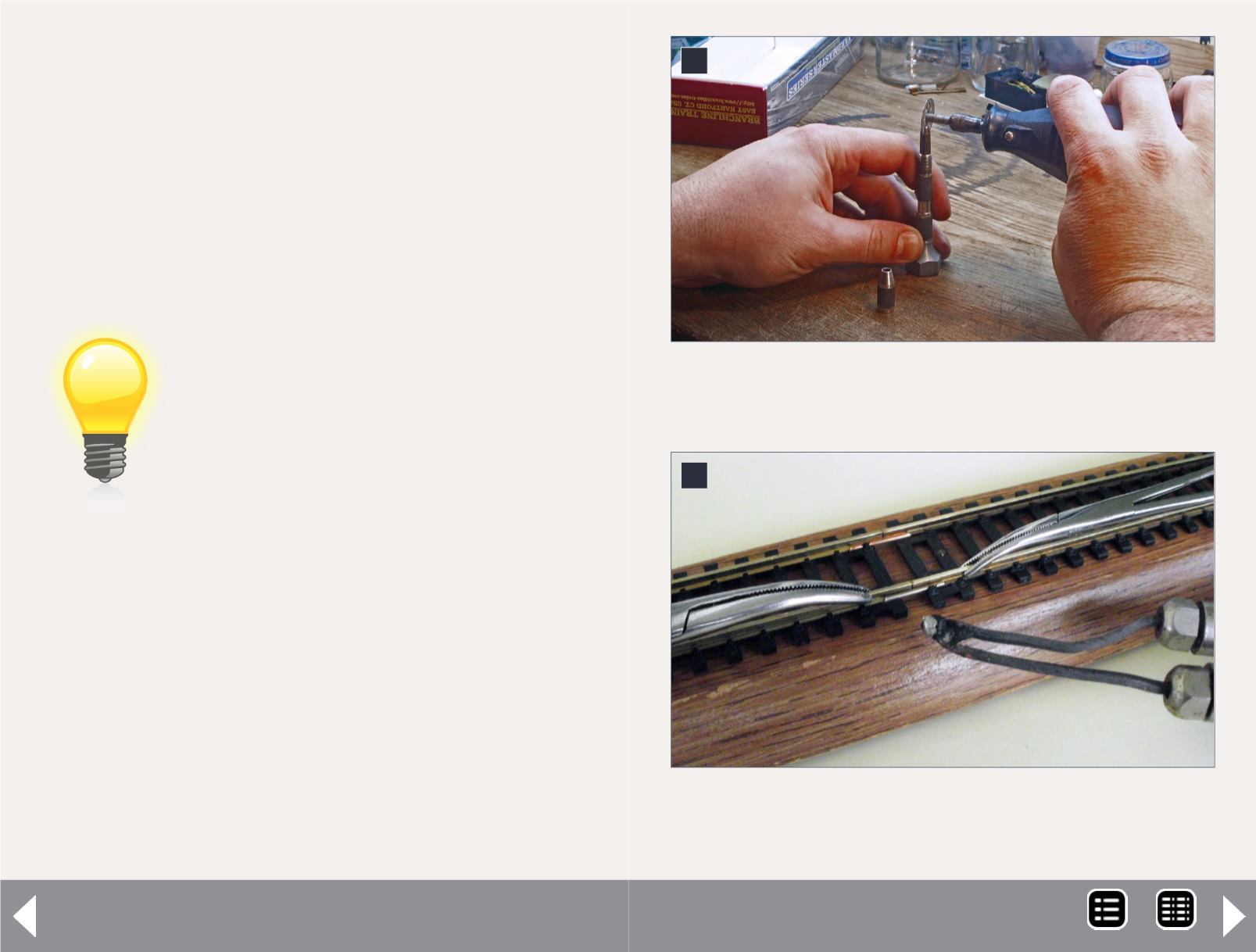

Revive a pin vise

After several years of use, my smallest pin vise chuck had worn to

the point that it would no longer close on very small bits. Rather

than replacing it, I renewed it by grinding away a little of the inside

faces of the jaws using a very thin diamond blade in a Dremel tool

[4 next page]. This restored the sharp corners of the jaws, allowing

them to close down to 0 again.

– Ken Rickman

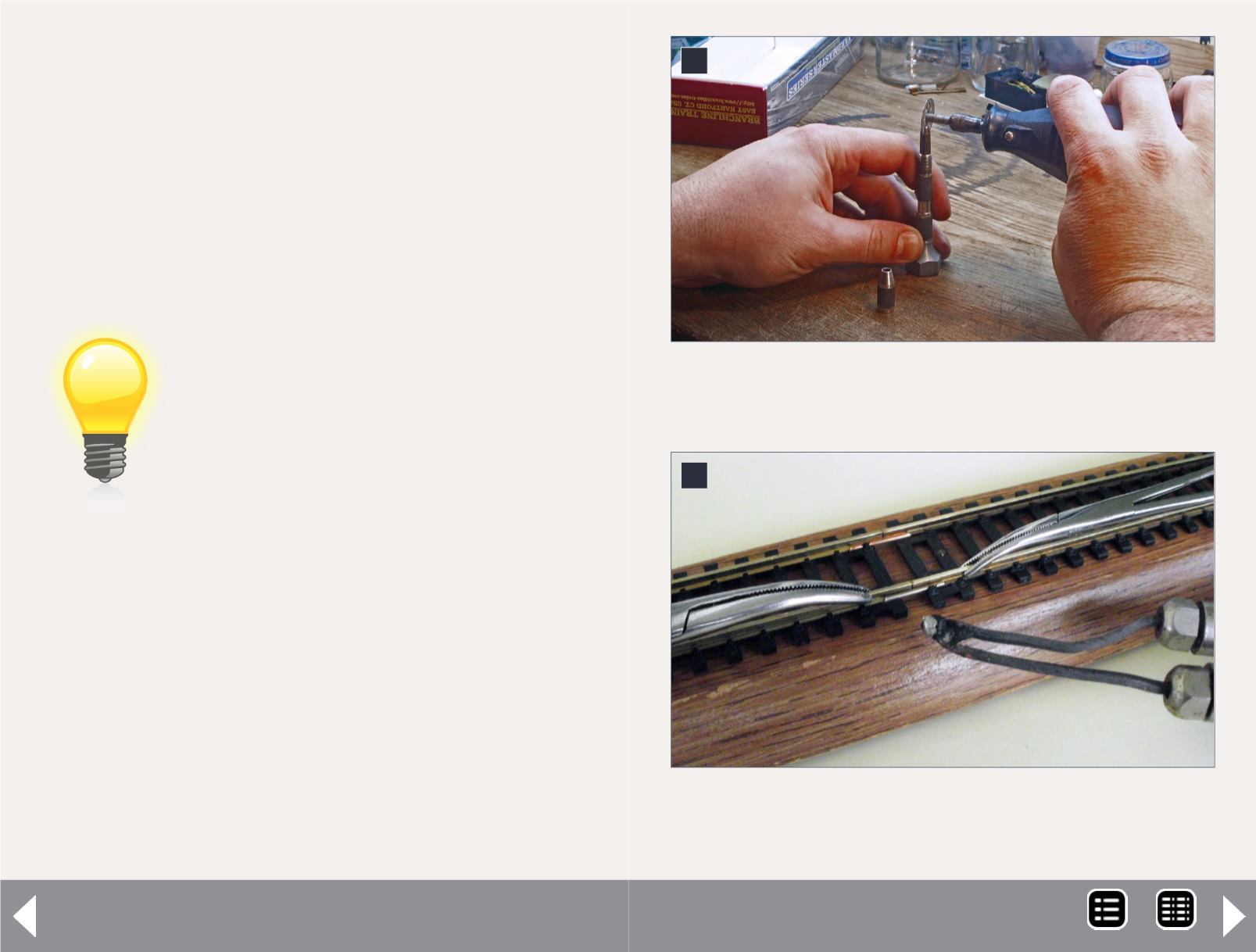

Soldering track joints

I don’t know if this is a new tip but it was shown to me by a mem-

ber of our Zephyrhills Railroad Museum club. When soldering a rail

Questions, Answers & Tips - 5

5. Clips on either side of a soldered rail joint draw heat

away from the work and keep plastic ties from melting.

Ronald D. Smith photo.

4

5

4. A thin diamond blade refaces worn pin vise collets.

Ken Rickman photo.

MRH-Sep 2014