prefer ME flex track for visible locations because of its superior

appearance.

Marking center lines

The MidWest Products cork roadbed I use needs to be split in

two along a pre-cut diagonal. Then, the two pieces are glued

in place back-to-back with their beveled edges (more or less)

simulating a ballast profile.

If care is taken to closely align the cork roadbed when gluing it,

the seam between the two pieces can be used to guide track

placement. But I always lightly sand the cork to smooth the top

surface and this makes it hard to see the center seam.

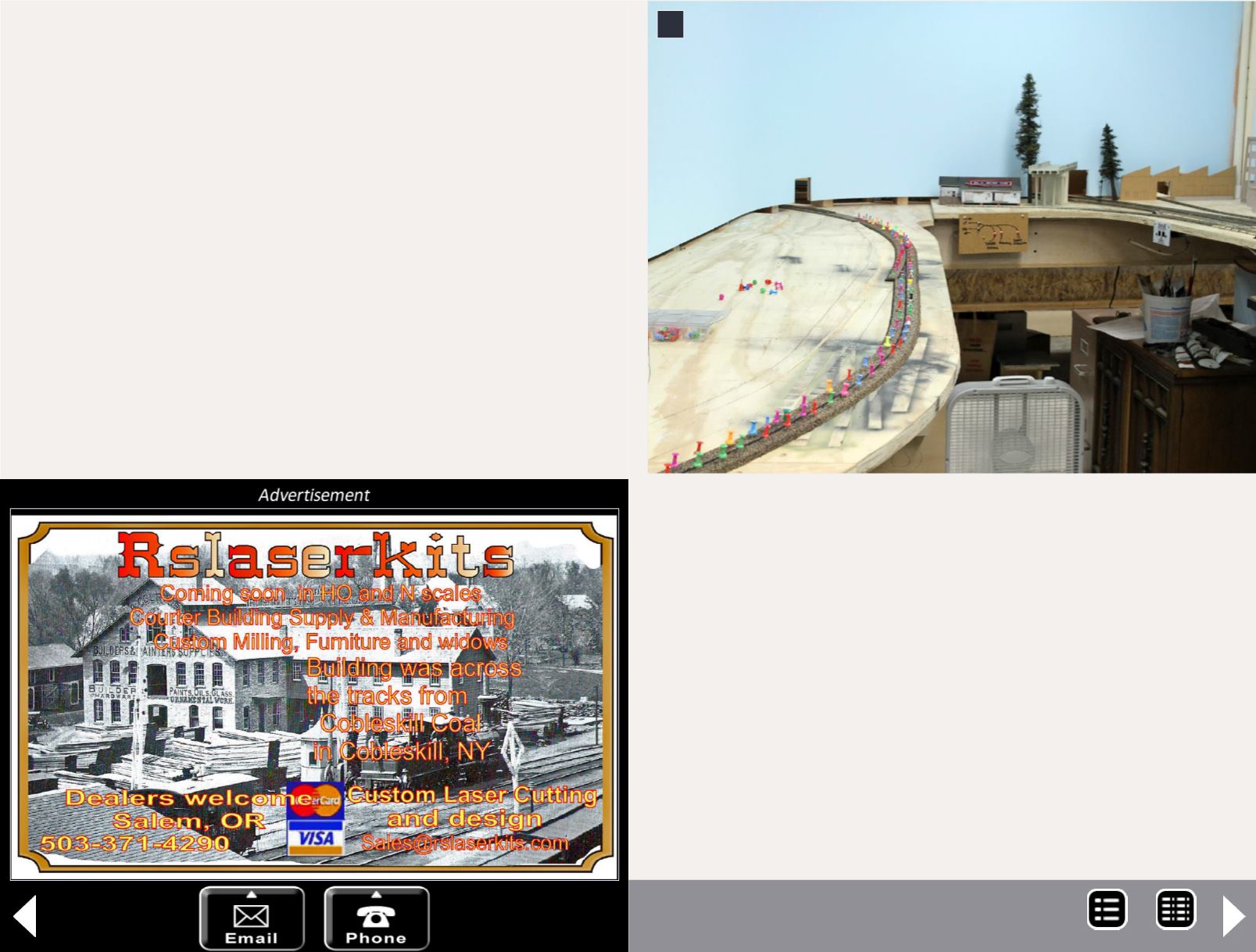

5. With the sub-roadbed in place, I started to glue

down cork roadbed. This area of Browning is on a 1%

grade, descending toward the backdrop.

5

For a year or two I’ve been marking the edge of each cork strip

with a Sharpie black marking pen. Now the center line is clearly

visible after sanding [6, 8].

I spread yellow glue, then smoosh the cork into the glue and

hold it in place with map tacks. After the glue dries I remove

the map tacks, and use a 16” long block of particle board

wrapped with 60 grit sandpaper to smooth the top [7]. Using

a long sanding block helps keep the cork’s surface flat. I also

lightly sand the outside edges of the cork to remove roughness

left when I split the cork into two pieces.

Up the Creek Column - 4

MRH-Sep 2014