Intro to 3D modeling - 3

The positional accuracy of the system is quite good, about 0.2%

or 0.002” per inch. So rather than make a master from which I

would create a mold, I decided to make a mold box that would

produce the mold directly. I asked the Shapeways technical

people if anyone had ever done this and the answer was “No,

never.” It would be an inexpensive experiment so I went ahead

and gave it a try.

Overall, it worked pretty well, but there a couple of things to

watch. First, contrary to advertising claims, the surface is not

smooth. It feels smooth, but there are little grooves between

the rows of deposited plastic. Silicone rubber won’t stick to the

plastic, but it gets trapped in these grooves and is very difficult

to remove. I broke part

of the mold box prying

the RTV silicon from the

bottom of the box. The

surface finish on parts

from this mold made

them essentially useless.

Things couldn’t get any

worse so I applied a coat

of gloss finish to the mold

to fill these grooves, and

the second attempt at

making a silicone mold

worked well. Two coats of

gloss finish would prob-

ably be better, but you

have to be careful not to

obliterate the detail.

4

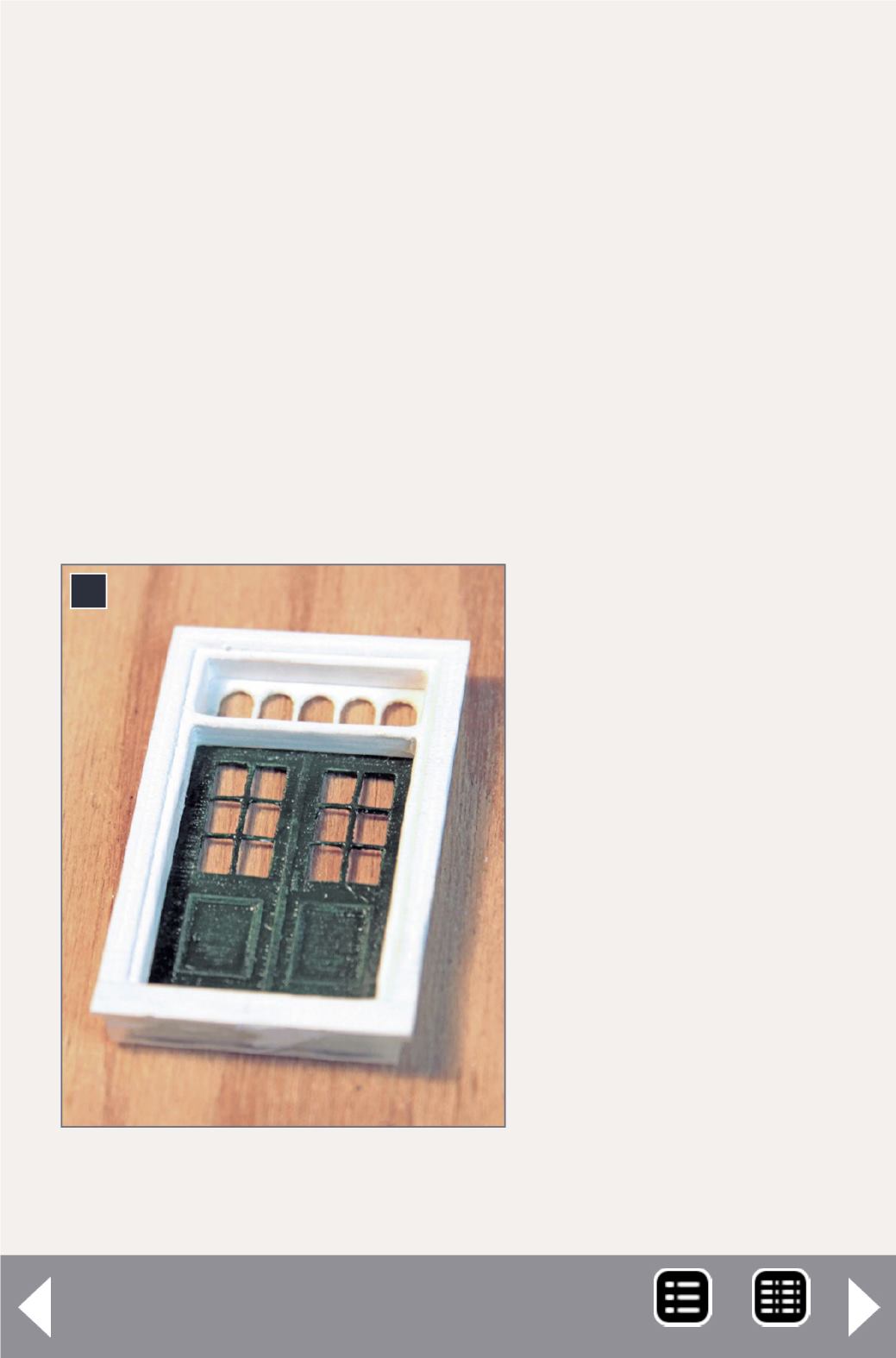

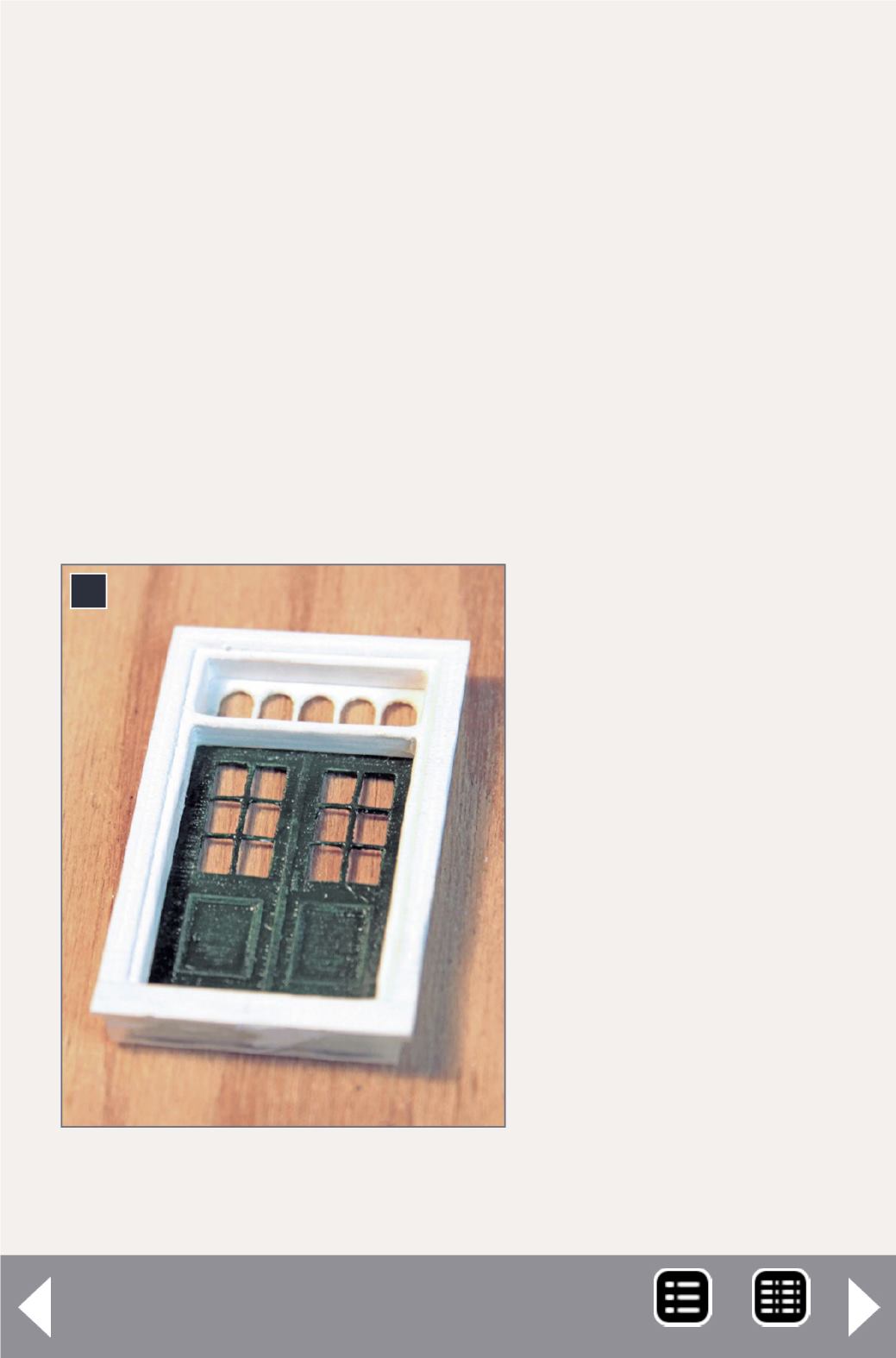

4. The door, painted and

assembled.

MRH-Aug 2014