Just one more step – scale it to the desired size. Select the

entire crate and with the Scale tool move one of the handles

to make it smaller and type “0.01148” (that’s 1/87.1, but

SketchUp doesn’t understand fractions) to reduce it to HO

scale. It will reduce to a tiny speck on the screen so use the

“Zoom Extents” tool to see it. I like to move it so the sides line

up with the drawing axes. Some older software requires that

the model be positioned in this way or it tries to print it out in

space. With it at the origin, there won’t be any problems.

Now we can play with one of the cool tools, the Section Plane.

Pick it up and click one of the surfaces of the crate. The green

tool will turn into an orange rectangle that creates a cut-

away section of the crate. Select it (it turns blue) and use the

move tool to move it through the crate to see any section

you like. This is useful to check that you meet minimum wall

thicknesses.

Now just go to the File menu, Select “Export Model/Collada

File. Say OK to the defaults. All software packages accept

ASCII data

and it must be

exported in the

same units as

you drew it, in

this case inches,

or it will change

size. E-mail the

Collada file to

Shapeways and

in a few days

you’ll have the

physical part.

You can use the

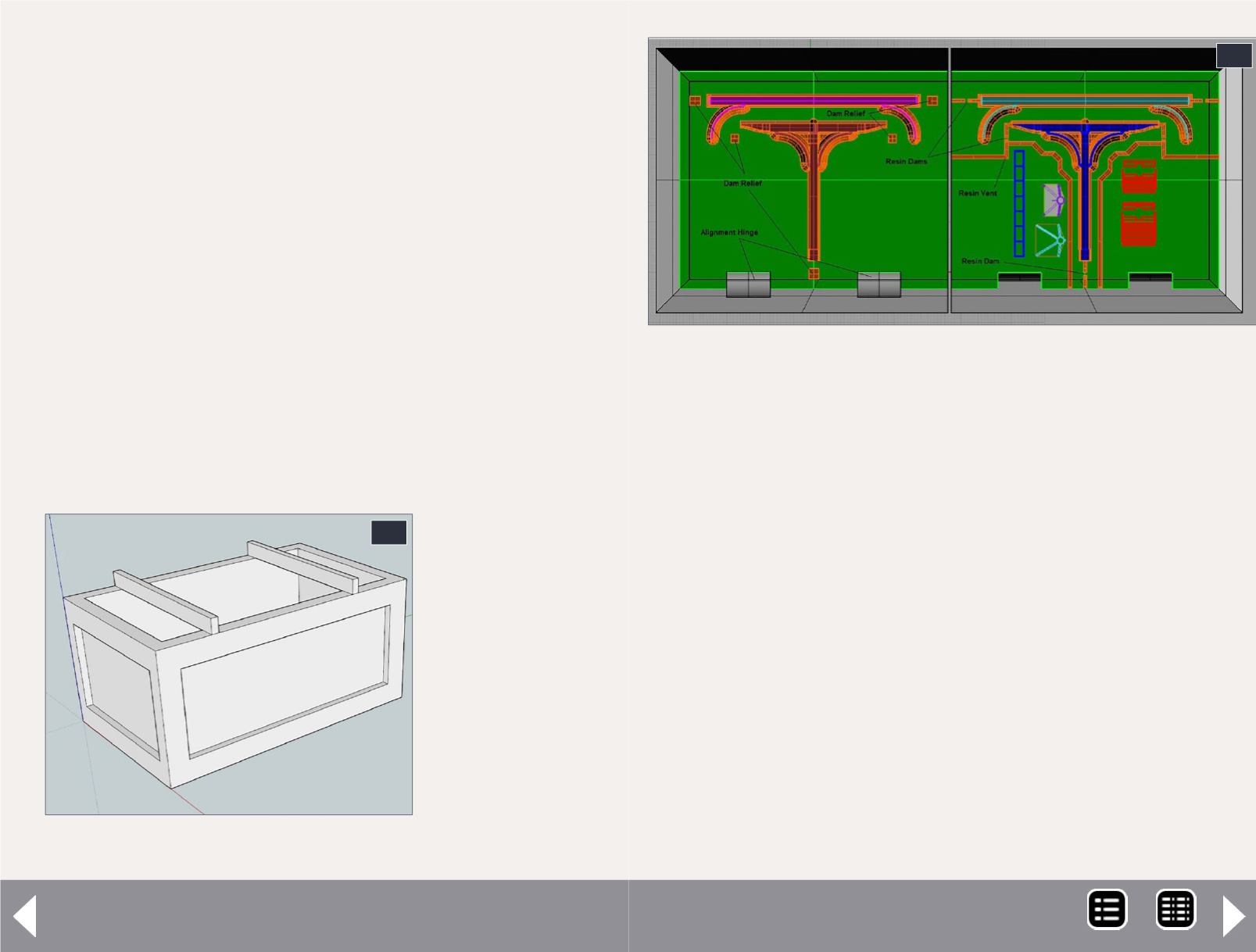

11. Crate with 2x4 spacers.

11

Intro to 3D modeling - 8

part directly on your layout or you can use it to make a mold

and make bunches of parts. To use this model as a master, fill

it with epoxy resin and then continue with conventional clay

mold-making techniques.

We have been working in the default perspective view.

Things are getting more complex, and I prefer to select

Parallel Projection in the Camera menu. Well, that’s it for the

SketchUp tutorial. You’re on your own to explore all the vari-

ous SketchUp tools.

Conclusion

What I have shown is just a basic outline of 3D modeling.

Although this not a perfect solution to building custom models,

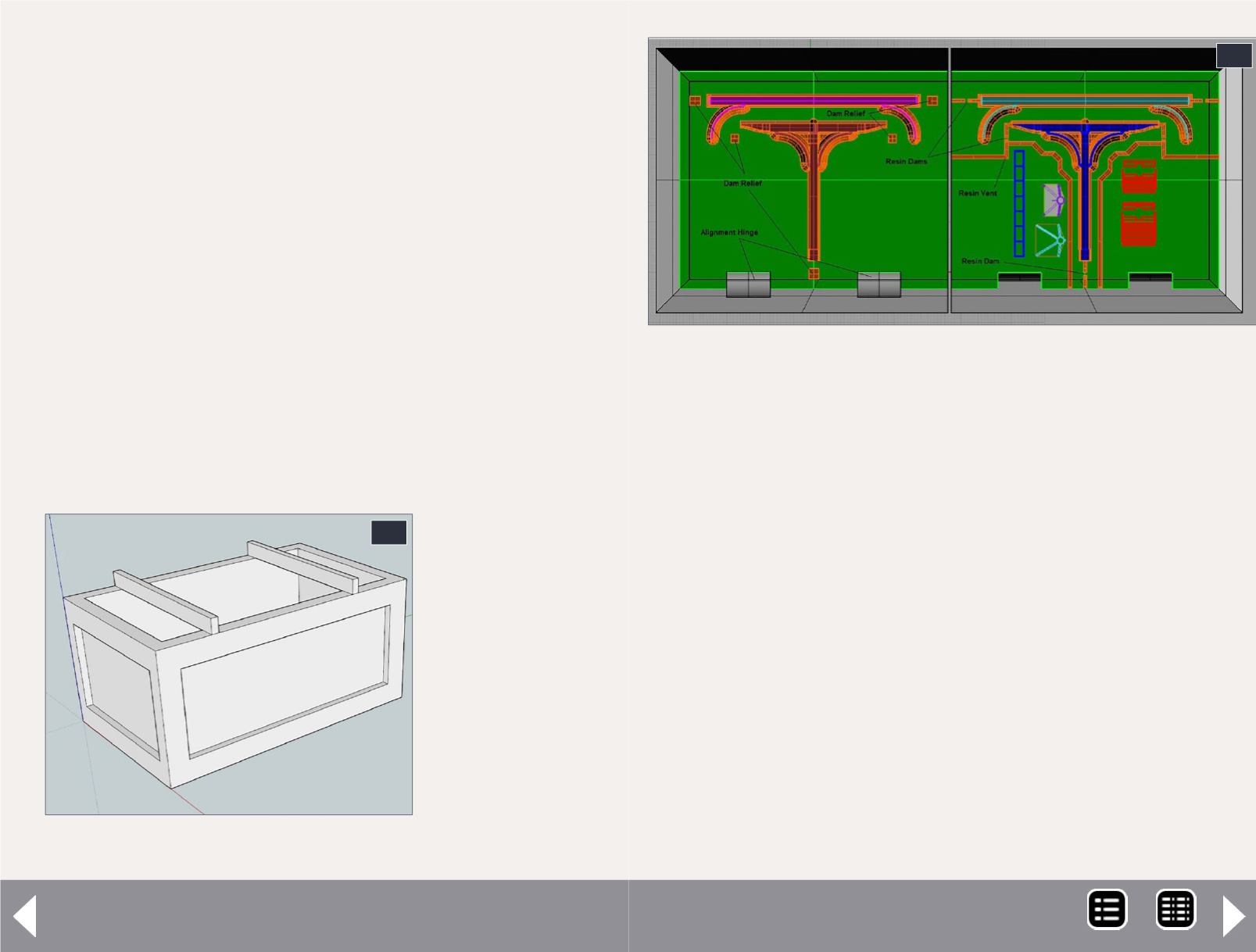

12. This is an example of a mold I made using Rhino.

Once the box is printed, I apply a gloss finish to

smooth out the mold. I then pour mold material into

the box creating my mold as shown in [2]. This goes

beyond the scope of this article, but I have shown it so

you know it can be done.

12

MRH-Aug 2014