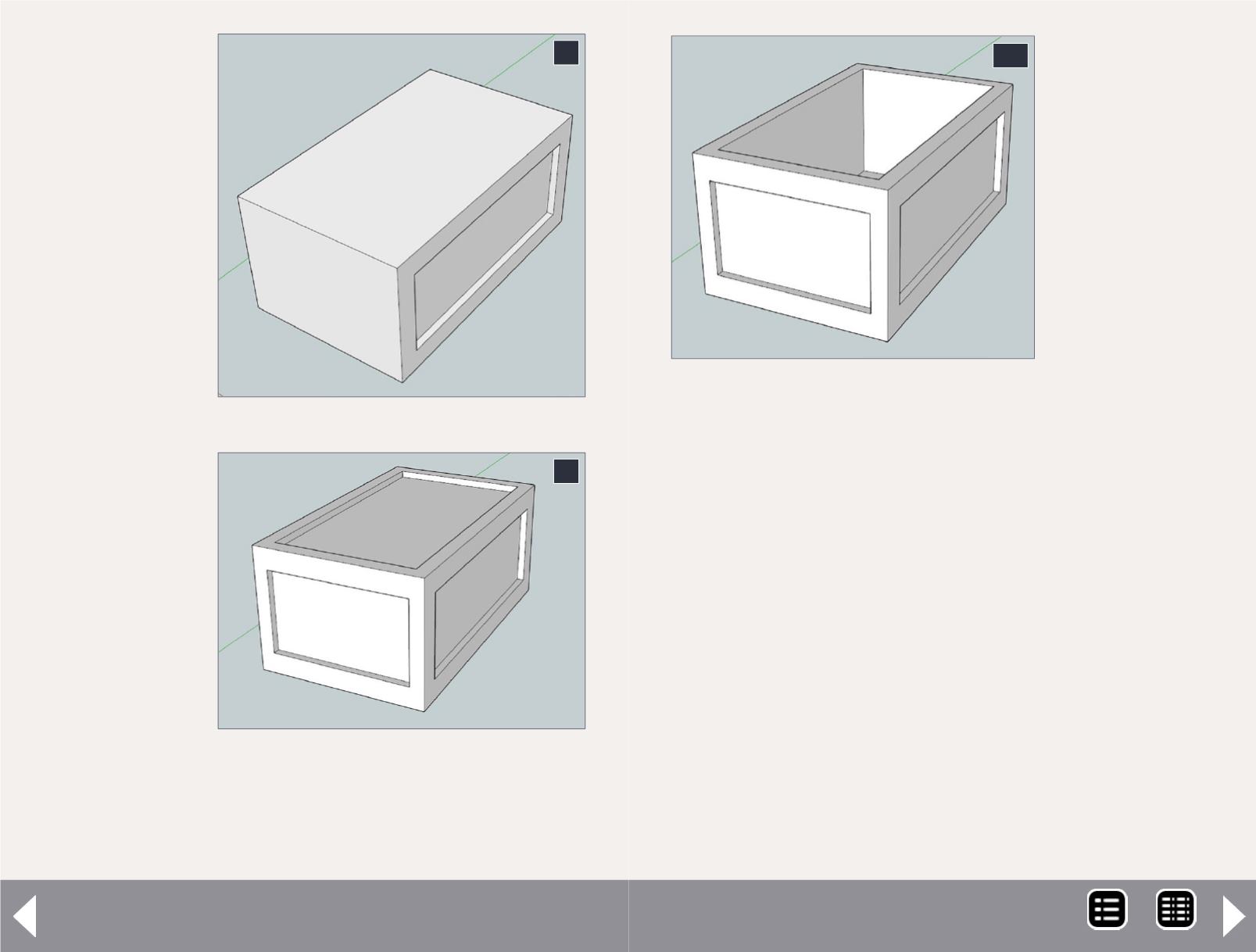

Repeat for the

opposing side

and top using

appropriate off-

set distances.

The ends are a

bit different. The

top and bottom

stiffeners should

be 6” wide, but

the sides should

be 4” wide. To do

this use the offset

tool and create

a rectangle with

a 6” offset. Take

the Move tool,

click the right

side of the inner

rectangle, move

it slightly to the

right, and type “2

Enter.” Similarly

move the left

side 2” to the left.

Push it in 2” and

you have as seen

in [9]

Repeat on the

other end to fin-

ish the model.

You could export a Collada file and have a model made, but

you pay for volume and a solid model costs more. So we want

Intro to 3D modeling - 7

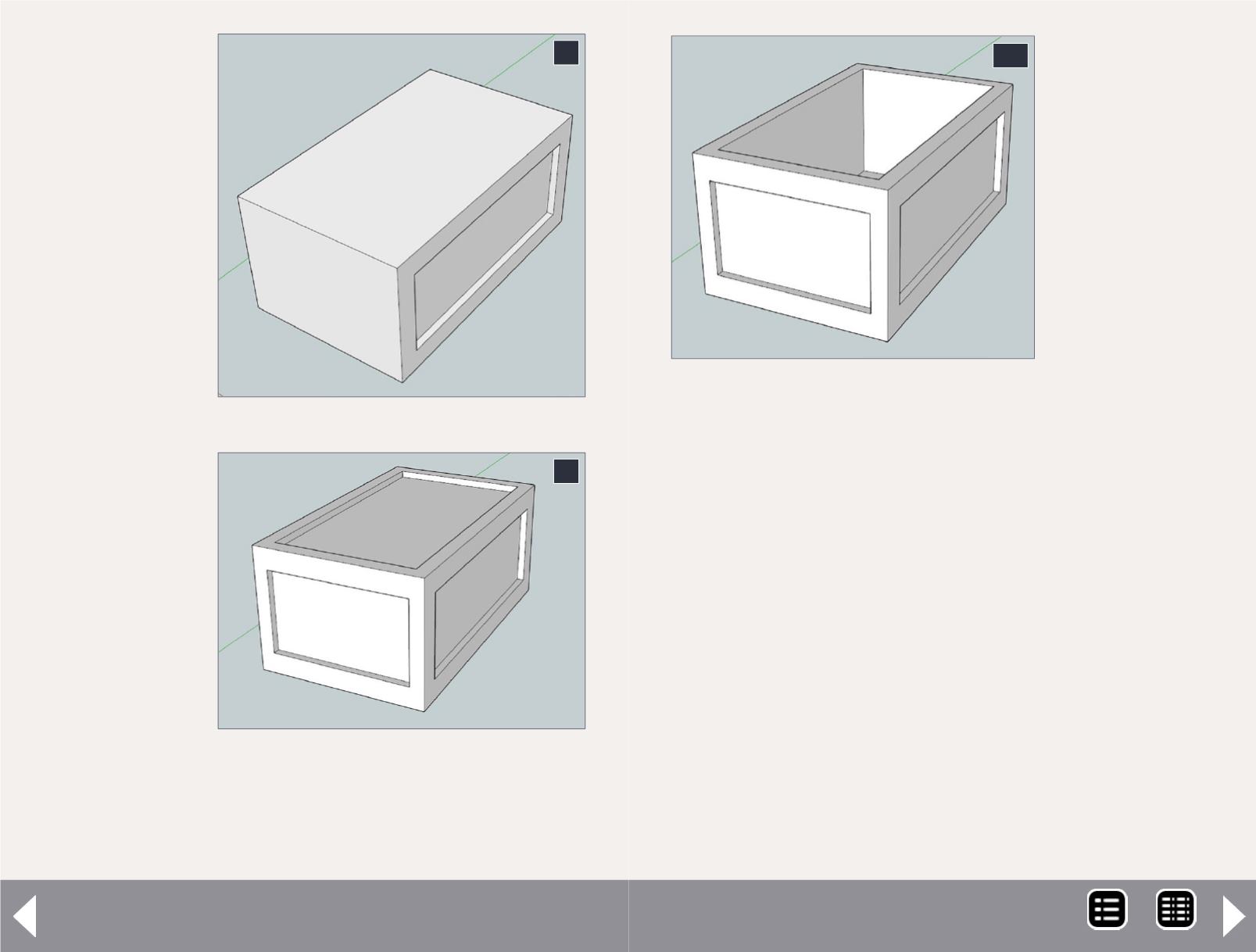

8. Crate with one side done.

8

9. The finished crate.

9

to make it hollow.

I use Shapeways

“Frosted Ultra

Detail” resin that

requires a minimum

wall thickness of

0.5 mm, about 2”

in HO scale. In this

case it’s easy. The

edges of the top

recessed rectangle

are 2” inboard from

the side recesses.

The overall height

of the crate is 36”

so the top and bot-

tom recesses are 32” apart. So just push the top recess down

another 30”.

Let’s put a couple of 2x4s on the bottom to stabilize the sides

and so a fork lift can get its forks under it. Construct a 2x48x4

box away from the crate. Select the entire 2x4 by making a

rectangle around it and with the Move tool, pick a corner and

move it so “On Edge” appears. There are a number of position-

ing aids available. They automatically appear when the align-

ment is close. I tried to capture them, but they do not appear

in the screen shots. The select tool is a bit different; once the

part is in the right location hold down the shift key to lock it in

place until you pick another tool. Otherwise the part just keeps

following the Move tool. Use the Select tool to select the 2x4

and copy it using “<ctrl> c”. Move it around until “On Edge”

appears (make sure it’s the right edge) and release it. You want

something that looks like [11].

10

10. A hollow crate.

MRH-Aug 2014