something. These didn’t last long in my tool drawer, and I

have basically found that the friction clamps don’t work very

well in the real world of modeling.

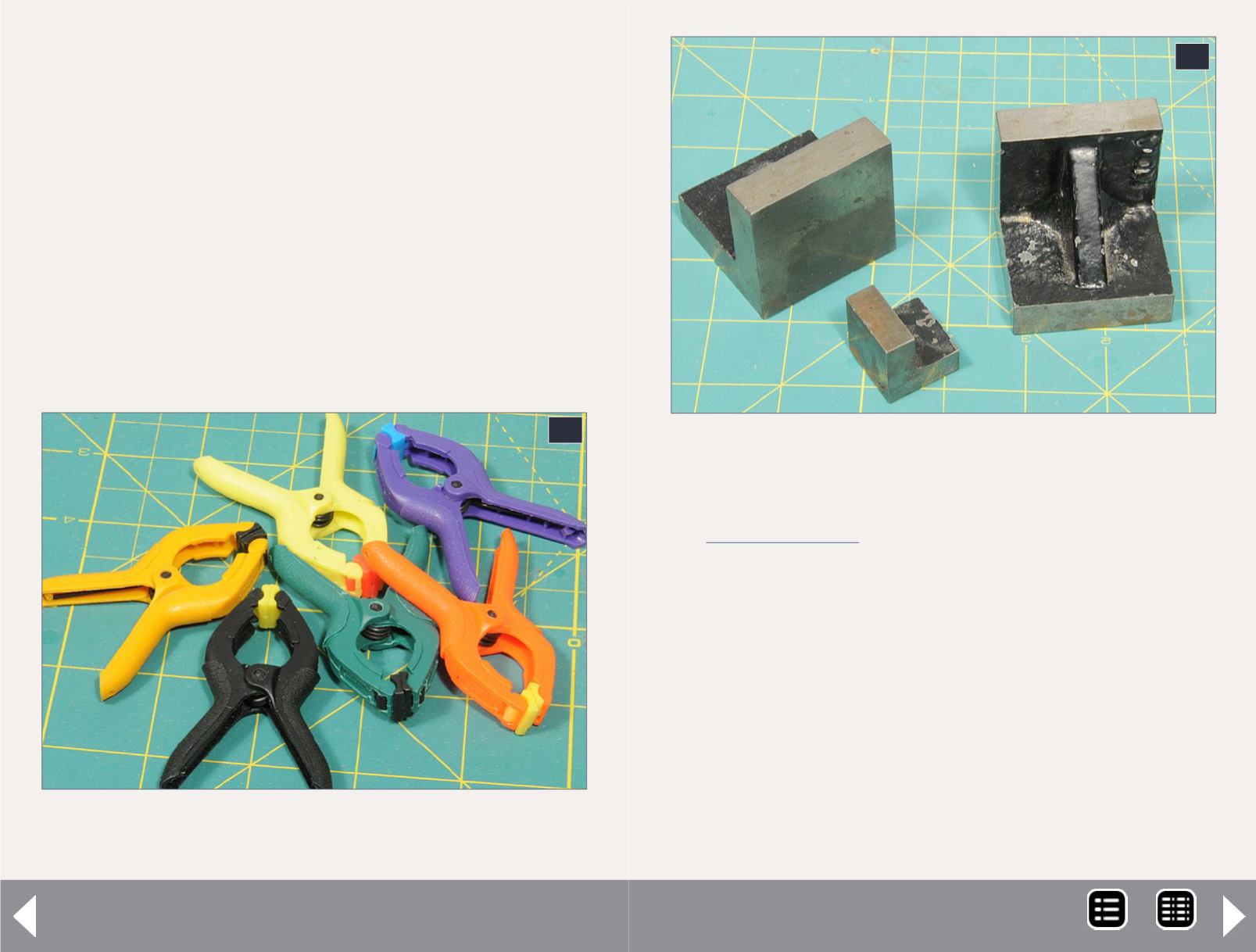

Spring clamps are the type of clamp I use most often, at

least when I need only a small clamping range. However it

is also important to make sure the clamp doesn’t apply too

much pressure to the modeling parts. As such, the clamps I

currently use most often are the clamps sold by Micro-Mark

called Miniature Spring Clamps (11). These clamps have a ¾″

capacity and don’t apply too much pressure for most jobs.

These are fairly common – I found a large bag of the same

clamps at my local ACE hardware store.

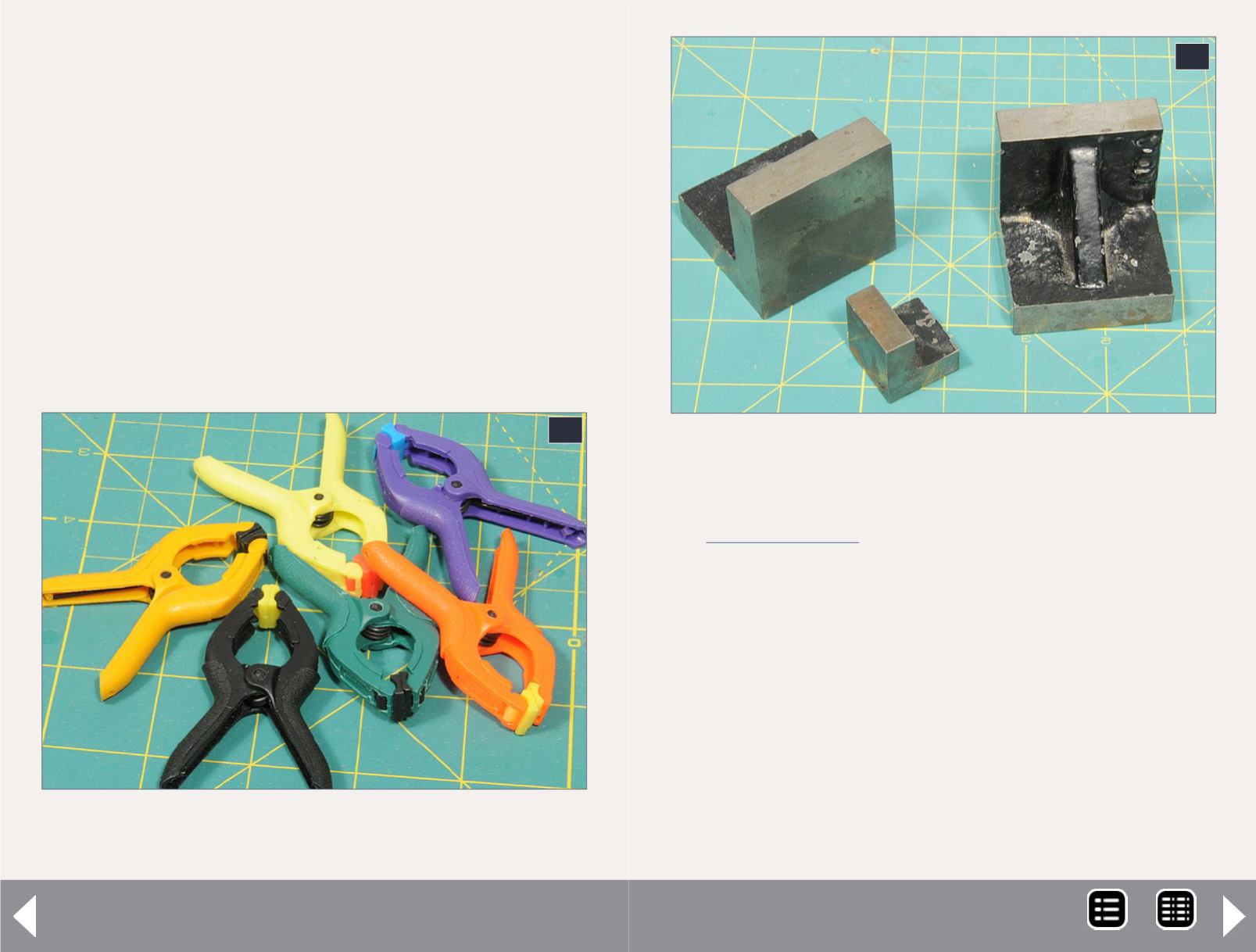

12: These angle plates were purchased from Micro-Mark.

11: Spring clamps like these are available from Micro-

Mark as well as some hardware stores.

My favorite clamps for building resin freight car kits are the

Coffman clamps that were discussed in a Tool Shed article in

the

Angle Plates

Angle plates are used with a milling machine to hold the

piece vertical while it being machined. Parts clamped to the

vertical surface can be held perpendicular to the table even

if they are not flat on the bottom. Angle plates normally

have T-slots so it can be securely fastened to a milling table.

I purchased my angle plates (12) from Micro-Mark. My large

ones are 2″ models, while my small one is 1″. They don’t

have T-slots or another way to hold them to a milling table

other than clamping them. While I don’t use them with my

milling machine, I do use them all the time when building

12

11

The Tool Shed - 6

MRH-Mar 2014