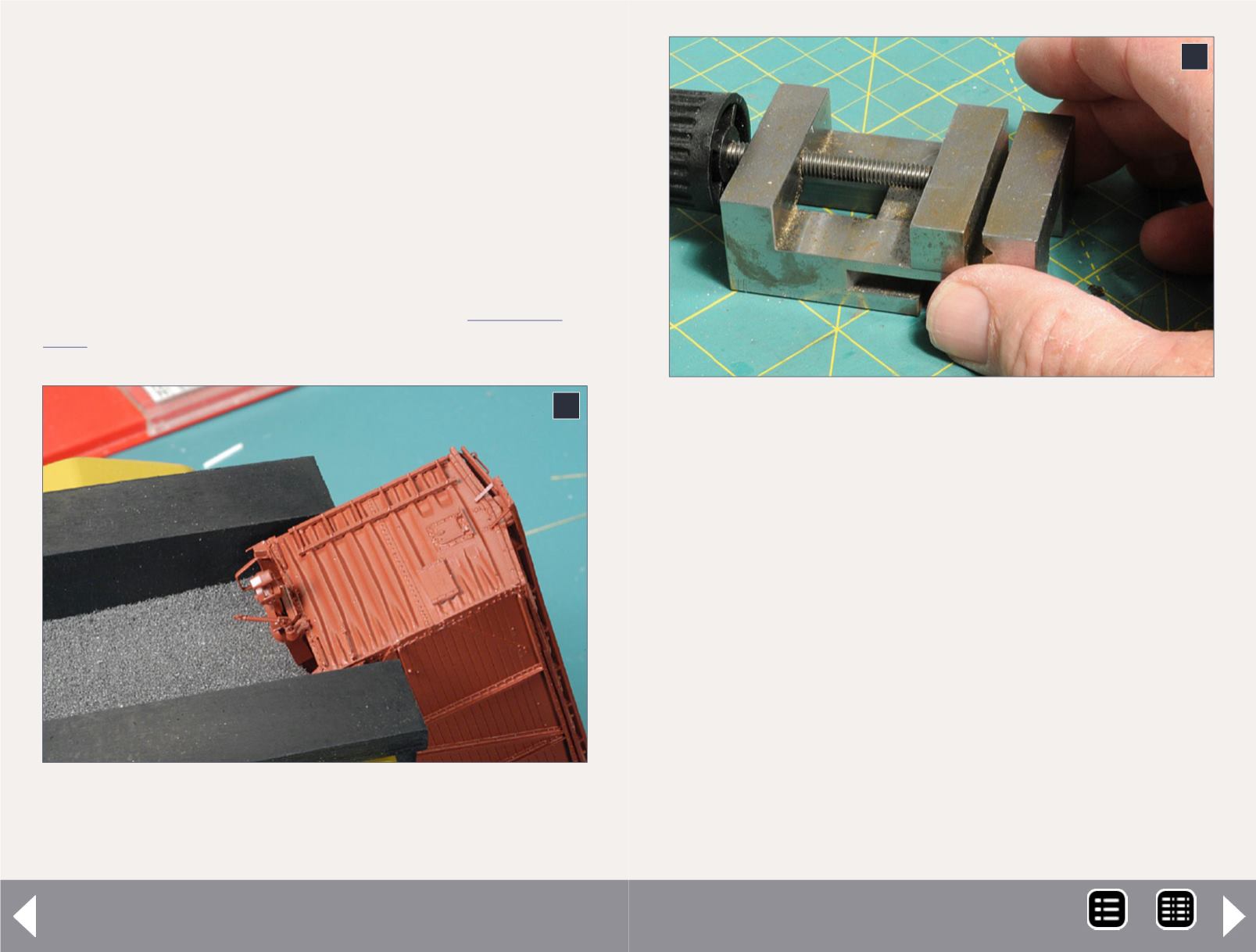

While the Unimat vise has both horizontal and vertical V

grooves for holding round rods, this vise only has a hori-

zontal V groove. However, the three sides of the vise are

square, which allows the vise to be positioned on one side

to hold a round rod vertically.

The finished top surface of this vise has another advantage.

If you need to place a part in this vise in order to drill a hole

in it, and you need to ensure the part is at a right angle to

the drill press, put the part upside-down on a flat surface

such as a glass plate, place the vise upside-down over the

part, and close the jaws. The part will then be parallel to the

top of the vise.

Clamps

Clamps seem to be a favorite modeling tool. I suspect

the first “Reader’s Tip” involving using wood clothespins

(reversed to result in the long flat ends being used for

5: This is my Proxxon Precision Machine Vise.

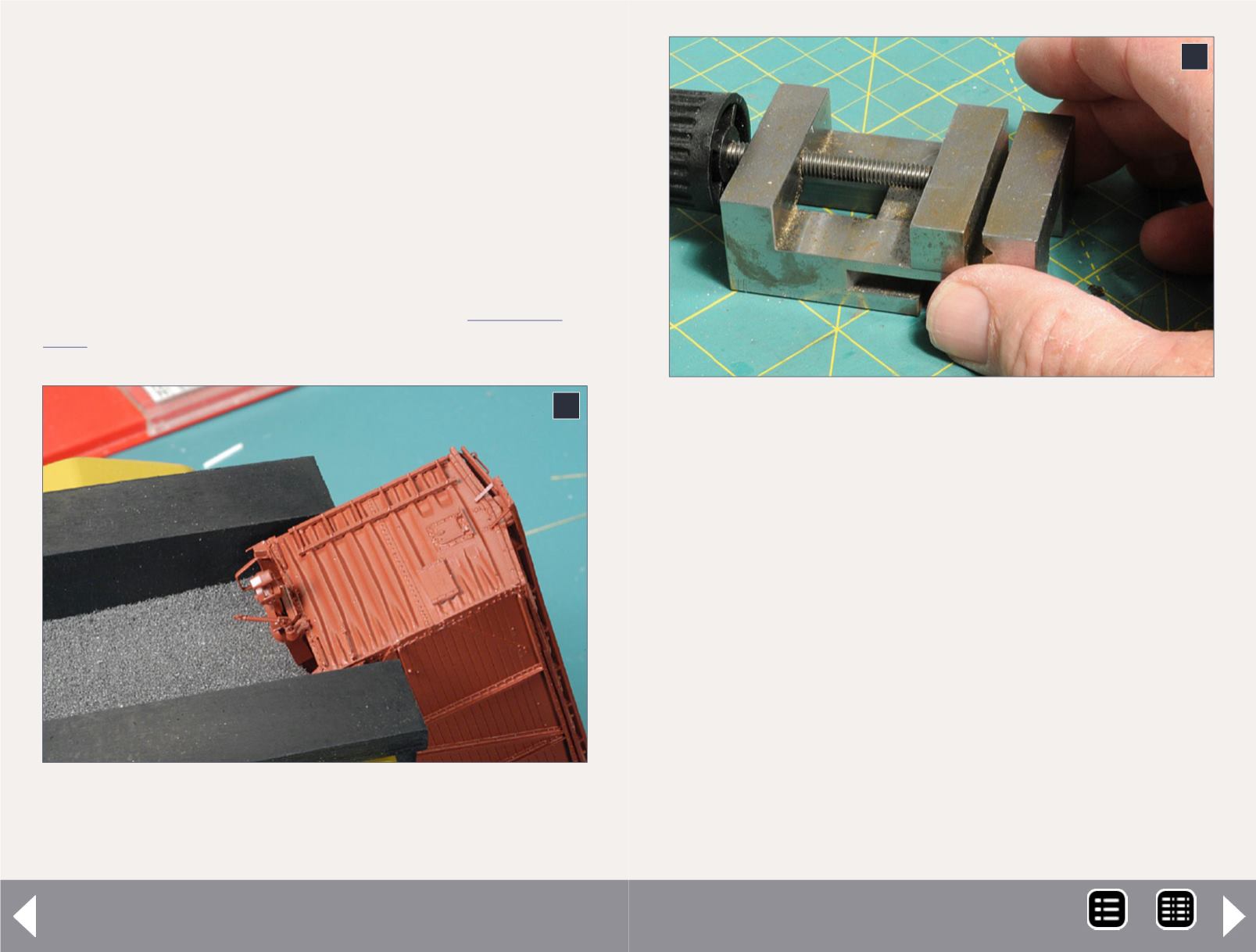

4: The top end of the car rests on a piece of soft foam

between the jaws. The jaws of the vise make just enough

contact with the car to keep it from rocking side-to-side.

5

4

to hold parts while drilling them. However, that Unimat

vise is fairly crude by today’s standards. After using it for

decades and having a “I need to buy a new tool” moment, I

decided to purchase a replacement vise. I chose a Proxxon

Precision Machine Vise which is shown in Photo 5. This is a

small, very nice vise with a smooth movement and a clamp-

ing capacity of just over 1¼″. It is not an inexpensive vise,

since the list price is more than even the Panavise. But while

I purchased it primarily to hold things while drilling them in

the drill press, I now find myself using it in a lot of different

situations, from supplementing my third hand

to holding parts for gluing or soldering.

The Tool Shed - 3

MRH-Mar 2014