clamping) first appeared in

Model Railroader

magazine in the

1940s. I too made up some of these clamps back in the 1970s

when there weren’t many options, but we now have many bet-

ter alternatives.

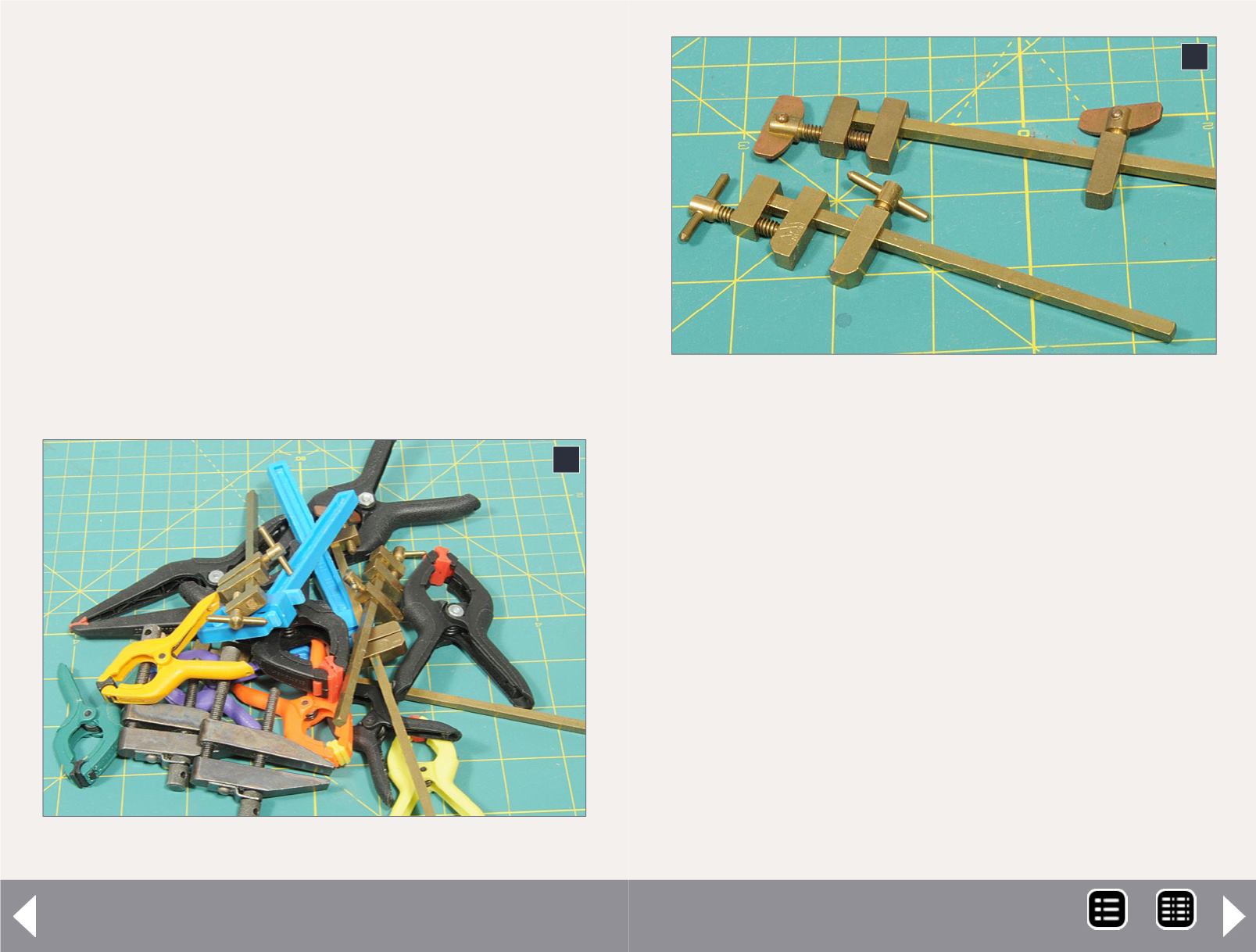

I’ve bought my share of different clamps over the years, all of

which I thought would be the last modeling clamps I would

ever “need” to purchase. Unfortunately, many of these didn’t

live up to their claims. You can see part of my current col-

lection of clamps in (6). Not shown are some small C clamps

and some small one-hand bar clamps; I even have some very

old small Delrin clamps which use rubber bands to provide

the clamping pressure; they actually work reasonably well,

although the rubber bands break at inappropriate times. I’m

sure they are no longer available.

Some clamps work fine and others don’t. Generally, once I

realize a clamp isn’t working out, I regulate it to a secondary

status. The box in my tool drawer for my clamps can actually

hold a lot more than I have, so there is no incentive to toss

out those clamps that don’t work. As long as I can quickly

find the clamp I want, the secondary ones get to stay for a

while longer.

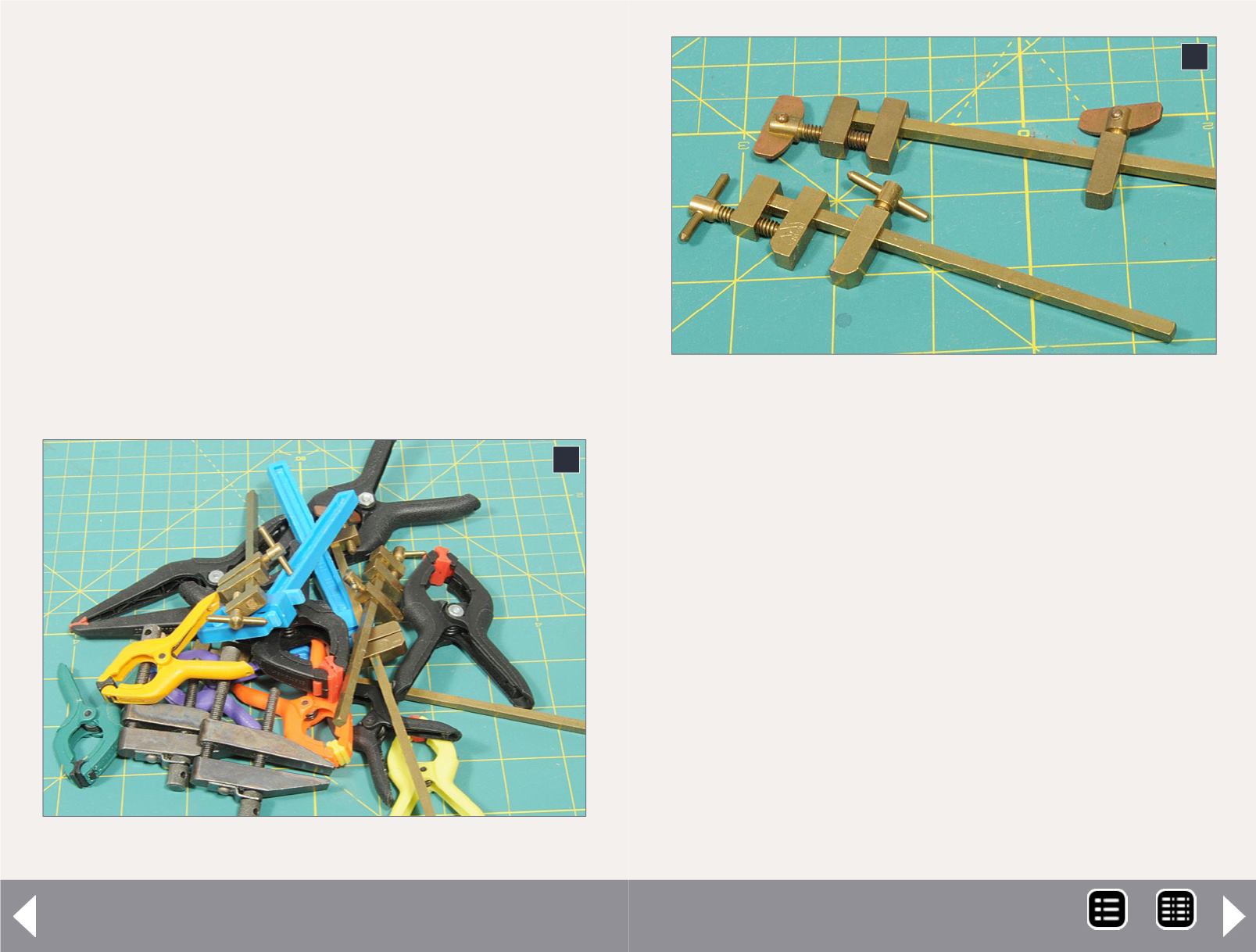

The brass bar clamps, as sold by Micro-Mark and shown in

(7), work as intended. These clamps might work well if you

build laser-cut wood structures and need to hold side/end

assemblies in place while the wood glue dries. To use one of

these clamps, you need to set the sliding jaw slightly wider

than the object being clamped before gluing the joints

together, but with the sliding jaw unlocked. Once the parts

are assembled, you can hold the assembly with one hand

7: Here are 3½" and 6" brass bar clamps. The wing head

thumb screw on top of the sliding jaw allows the jaw to be

locked in place, with final clamping provided by tightening the

end wing-head thumb screw.

6: I have over a dozen clamps. Here are just some of them.

7

6

The Tool Shed - 4

MRH-Mar 2014