Batch-building freight cars - 6

kit (hopefully with different car numbers) from your hobby

shop or by searching on eBay. Highly detailed kits include

Intermountain, Red Caboose, Proto 2000, Walthers Goldline,

and Branchline Blueprint series kits. Most of these kits were/

are sold in sets of up to 12 different car numbers.

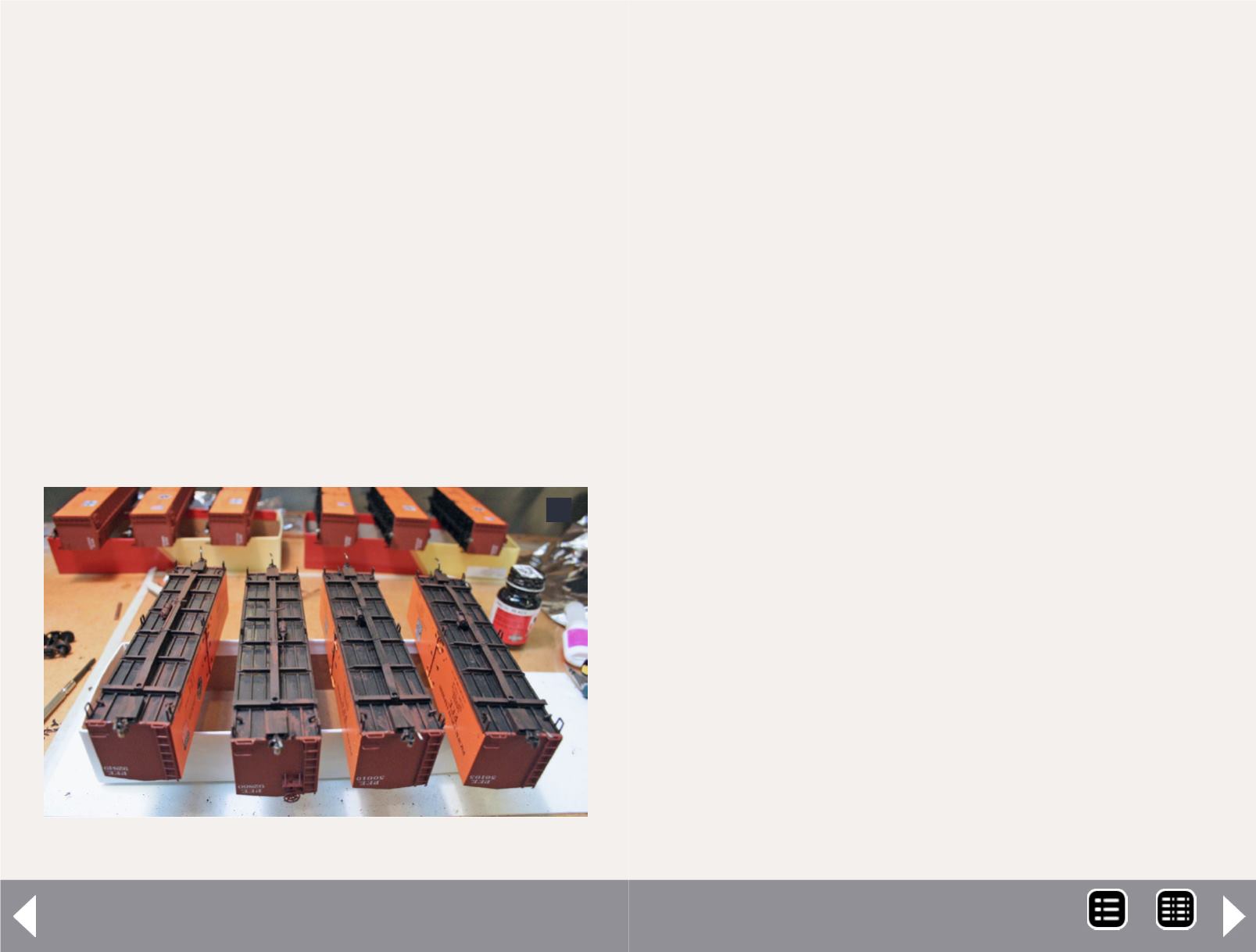

To start, Proto 2000 (P2K) kits stand out as a good choice for

batch-building. They are well-designed, highly detailed kits that

flooded the market in the early runs. They build up into crafts-

man-quality models. They have great metal wheelsets, and the

proper amount of weight is included in the kit. Look for tank

cars, stock cars, boxcars. gondolas, flats, war-emergency hop-

pers and PS II CD hoppers from the early runs. A good starter

batch might be a set of four P2K cars, or perhaps a set of four

Branchline Yardmaster series boxcars if you want to start out

with something easier. For the first attempt at batch-building, I

recommend staying away from unpainted kits.

Batch-building steps

First I will outline the basic steps of a batch-build and then I’ll

take you through a build of four Proto 2000 Stock cars.

The steps can be summarized as follows:

1. Study the directions and identify the subassemblies

2. Assess the trucks, wheels trucks, and couplers

3. Sort and unpack

4. Cut out and assemble

5. Road test and adjust

6. Add a little weathering

Now for a closer look at the various construction steps:

Step one: Study directions and identify

subassemblies

Study the instructions to familiarize yourself with the specifics

of the kit construction. Typically kits are put together in sub-

assemblies: The roof, the underbody, the car ends, and then

usually the body. I generally build one kit first, or build up the

subassemblies ahead of the batch, just to make sure there

are no surprises. It’s far better to make an error once, instead

of four times (or 12 times, if the batch is big)! This also elimi-

nates mistakes in the directions about the order of assembly.

Plan to include weathering as part of the construction process,

since it is easier to weather certain parts of the cars as they are

put together as opposed to taking them apart after assembly

(especially wheels and trucks).

Step two: Trucks, wheels and couplers

Now is the time to assess the quality and reliability of the

trucks and couplers, if they are supplied with the kit. Since the

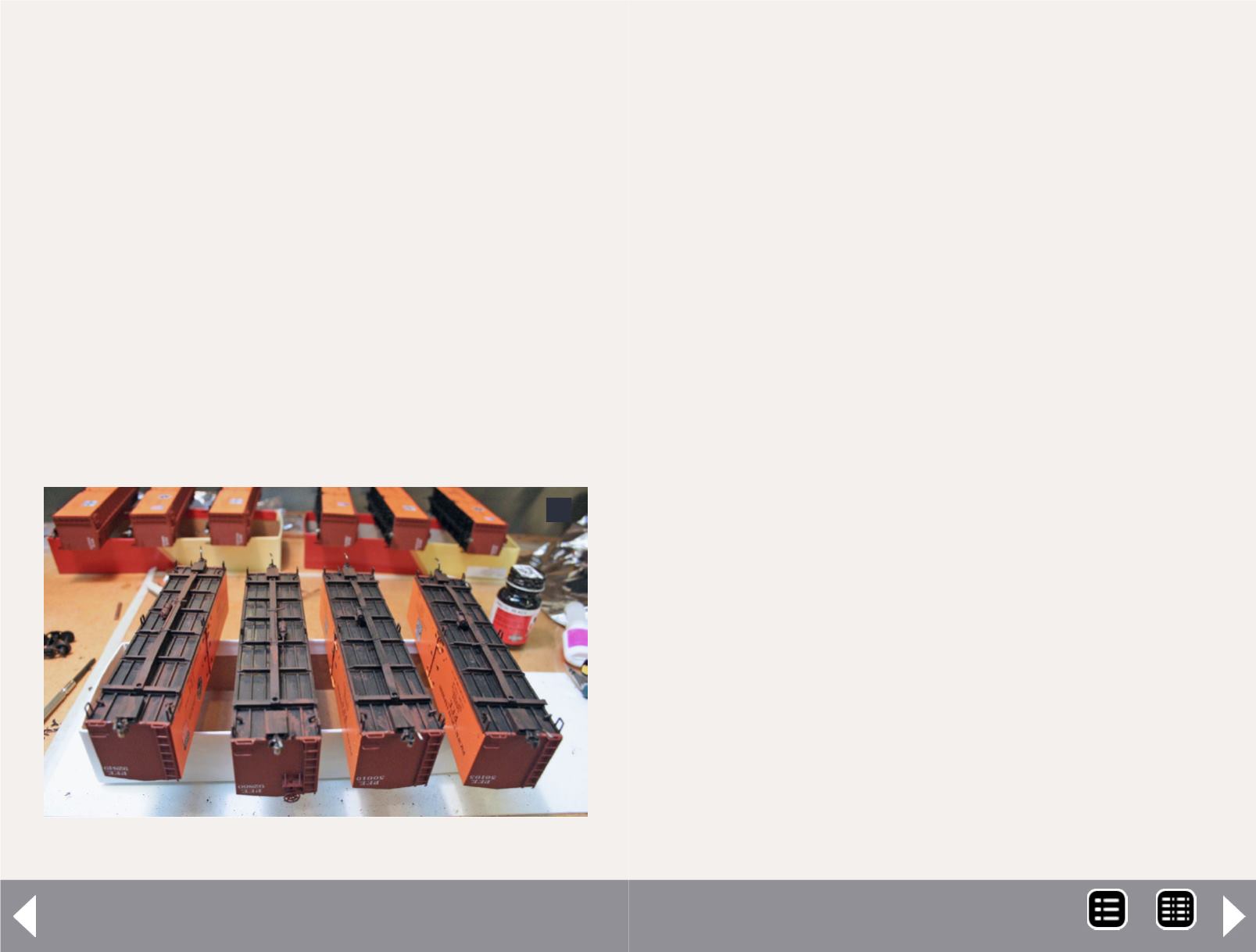

9: A few reefer body assemblies await roofs.

9

MRH-Mar 2014