beneath each silo, and cut each chute into lengths 1.15” long.

The assembled auger and chutes were then placed on the silo

base so I could construct the supports using .100” I-beams.

Three pieces of .100” I-beams were used to support each chute

assembly while .125” I-beams were used for the main auger

assembly, one on either side of the chutes [20].

Once the entire assembly was completed, I went ahead with

painting and weathering, since doing this after the silos were in

place wouldn’t be possible.

After the auger assembly was complete and permanently glued

in place, the last step was adding .020” by .060” diagonal brac-

ing between each silo support, and horizontal .060” angle at

the base of each column.

25

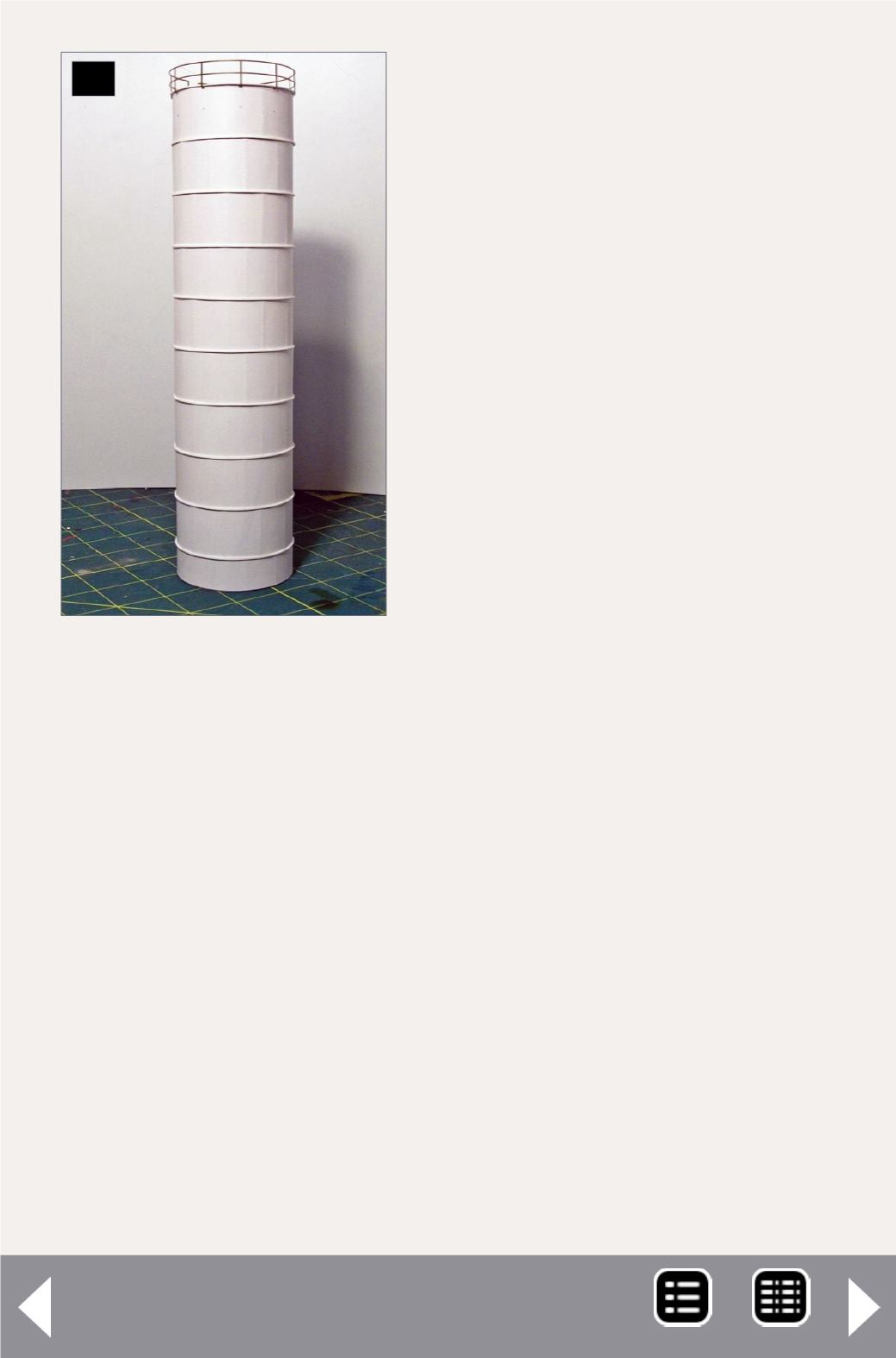

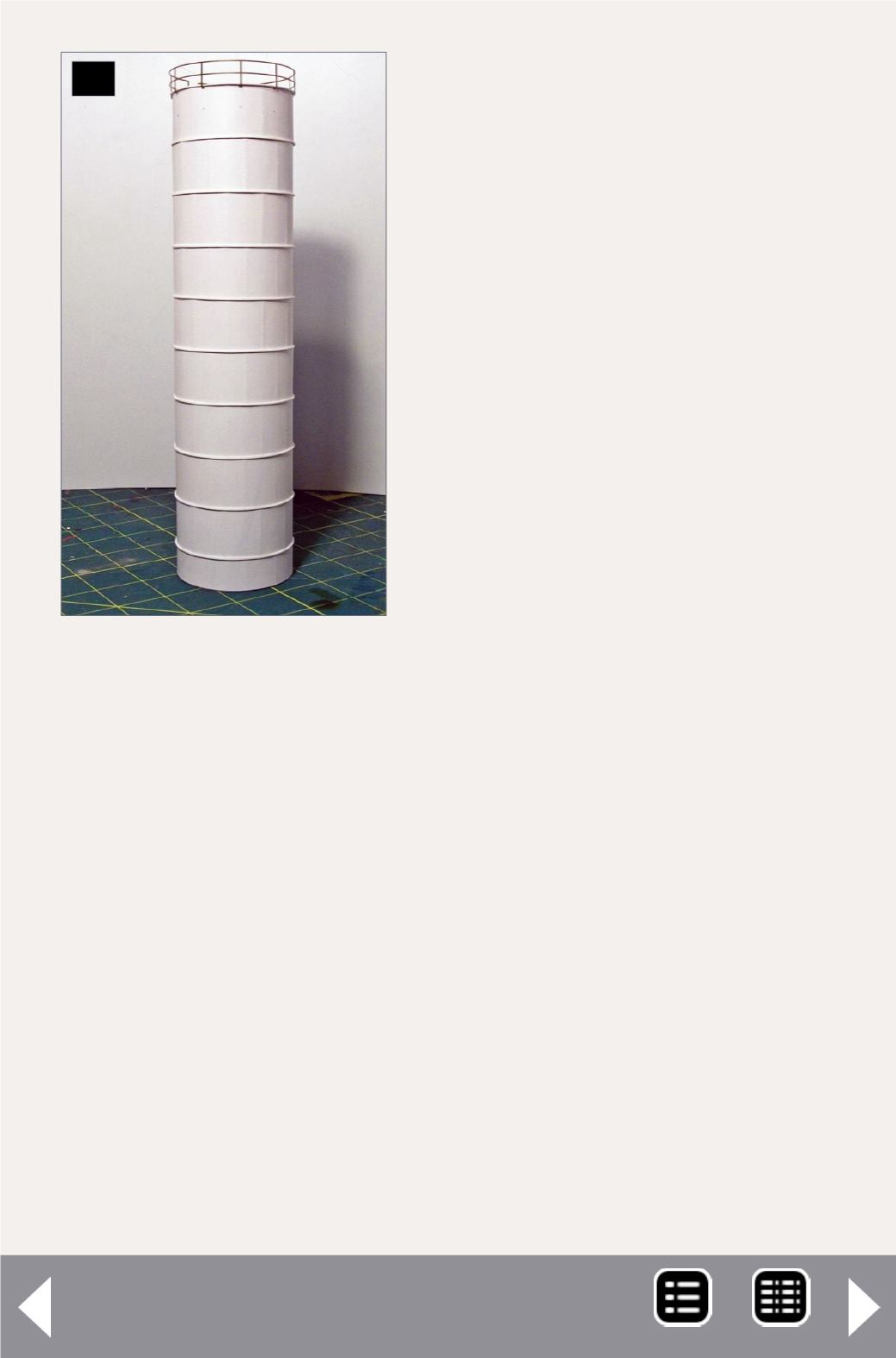

25. This view shows the

completed silo with the

vertical rivets visible on each

silo and the brass handrails

from Mike Rose Hobbies.

Note the panels were offset

so that the vertical rivet lines

alternated between each

panel.