With the silos completed, I temporarily placed each one in

place so that I could lay out the main auger trunk line running

the length of the silo base, and the locations of the chutes

that connected each silo to the main auger. The augers them-

selves were assembled from ¼” styrene tubing with a piece of

.020” thick by .40” wide piece of strip styrene attached to the

tubing lengthwise. Two pieces of .030” by .040” styrene were

placed on either side of the tube, and a strip of .010” styrene

was wrapped around the tubing in a U-shape [20 and 21]. The

wrapped styrene required several applications of body putty

and sanding to get a smooth seam, but ultimately I wasn’t wor-

ried about being perfect, since the detail was hidden beneath

the silos and bracing.

Once the main auger was complete, I followed the same pro-

cess, with slightly smaller .219”

tubing for the chutes that run

perpendicular to the main auger

Agway Feed Mill - 13

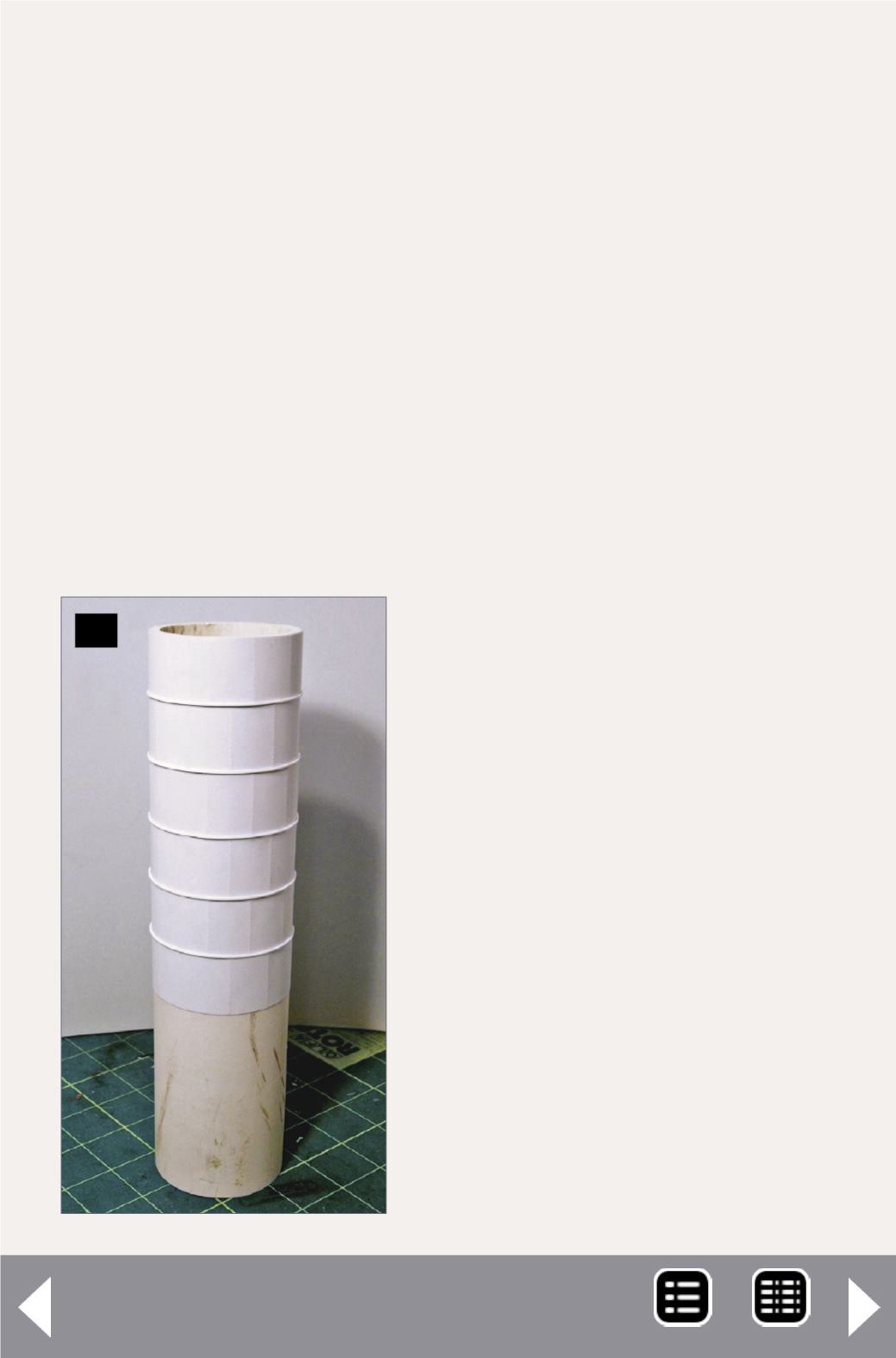

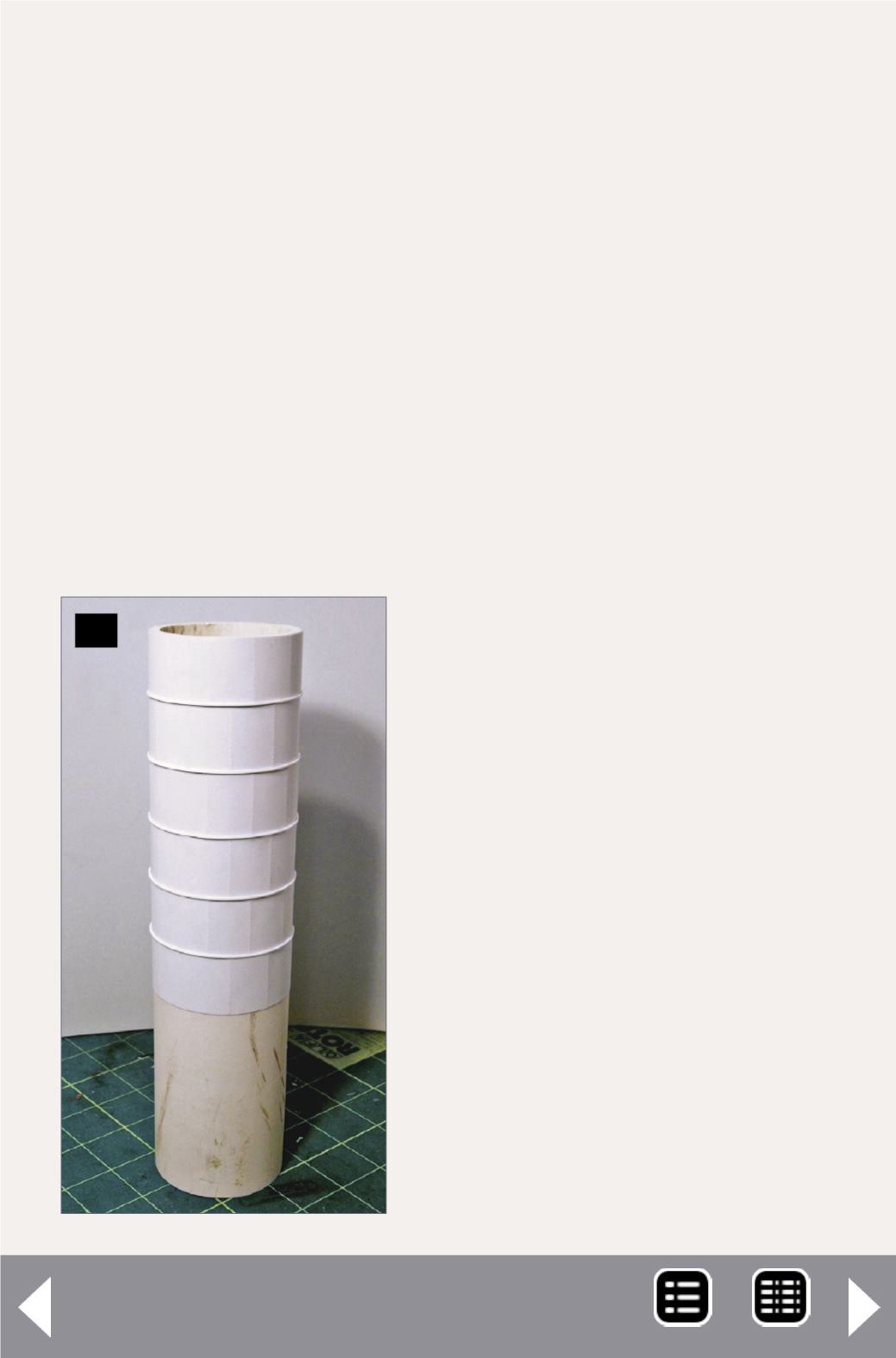

24. In this view, the styrene

panels are being applied to

the end silo. The end silo

construction differed than

the other silos as each panel

was separately wrapped with

styrene. The panels were

seven scale feet in height with

rivets punched every five feet

with overall circumference of

54.2 scale feet. Between each

panel was a piece of .030”

by .030” piece of styrene to

match the prototype.

24

MRH-Sep 2014